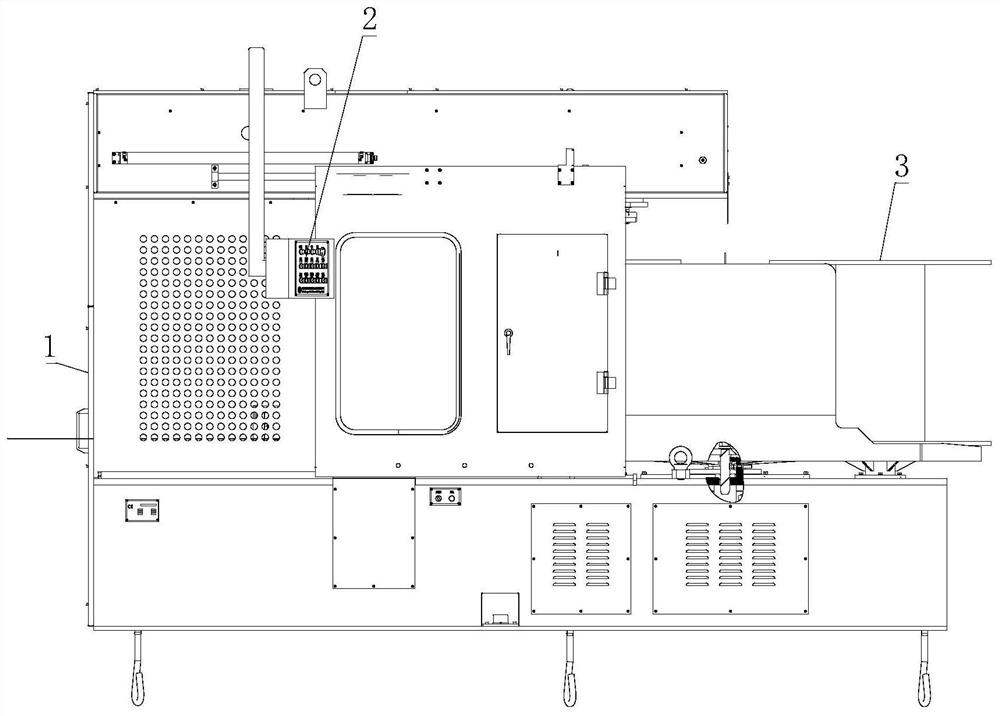

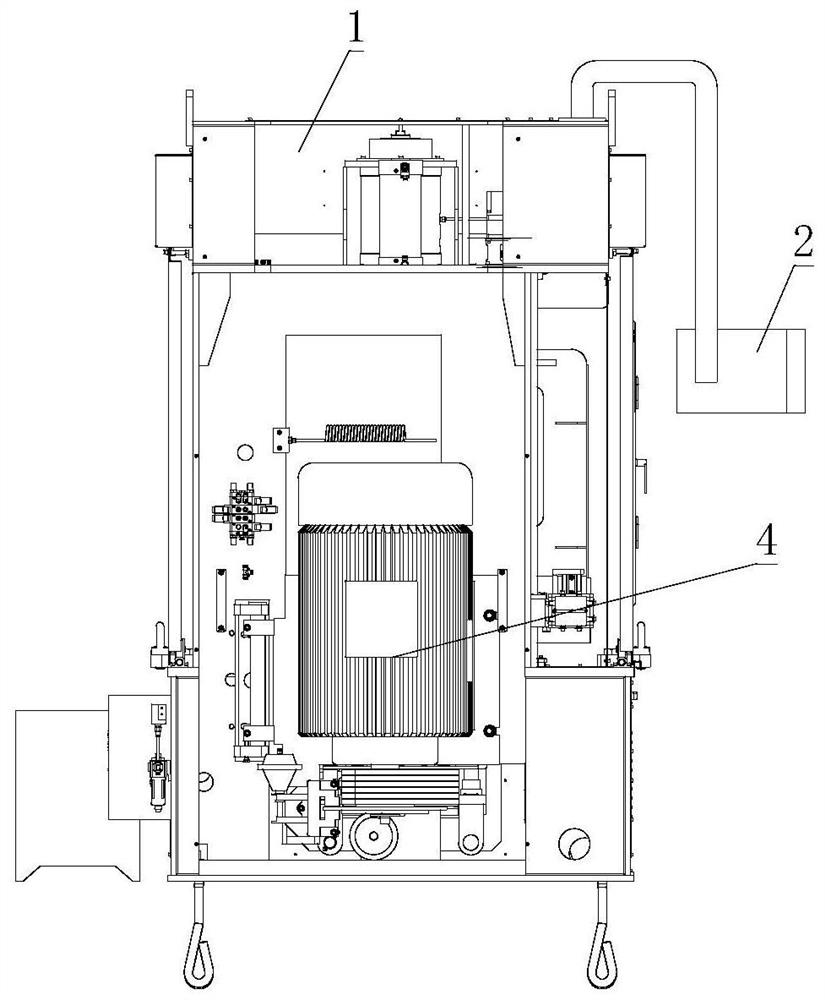

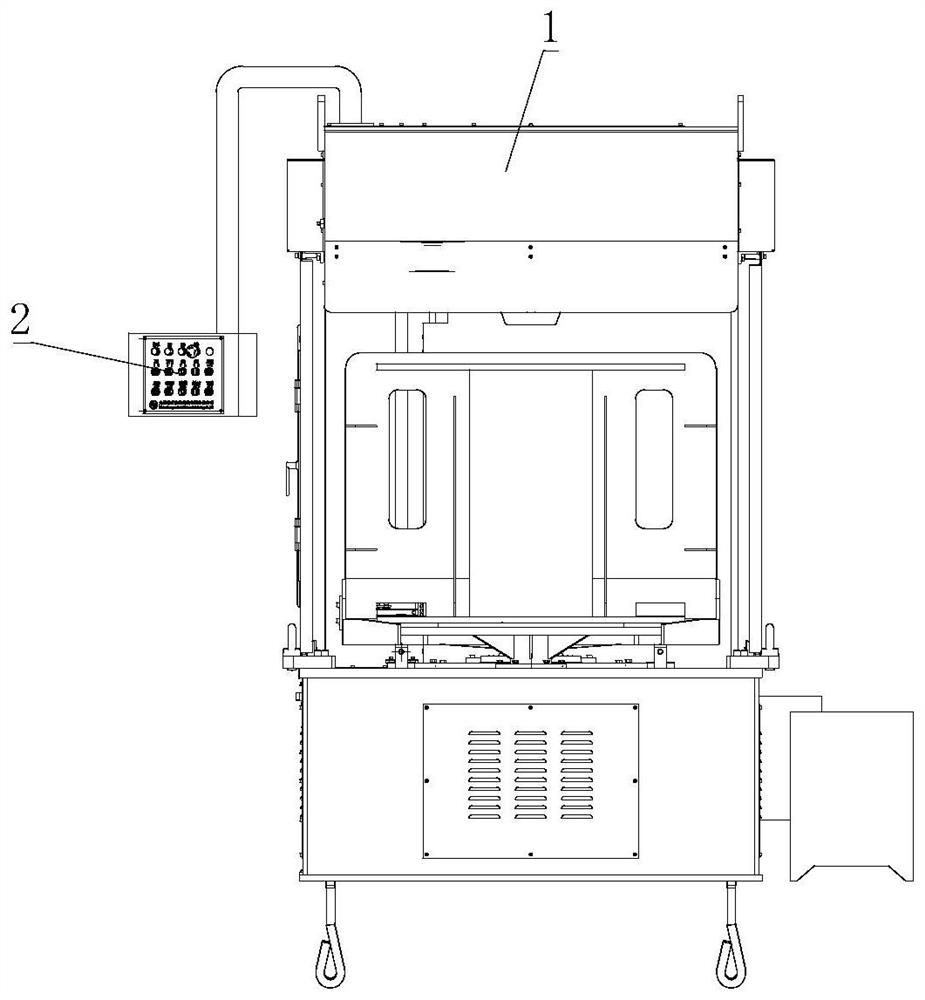

Vertical double-station wire winding machine

A dual-station and wire take-up technology, applied in the field of vertical double-station wire take-up, can solve the problems of slippage of the take-up disc and failure of wire take-up, and achieve the effects of reducing load, improving production efficiency and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

[0049] like Figure 1 to Figure 22 As shown, a vertical double-station wire take-up machine according to the present invention includes a frame 1, a wire take-up drive mechanism 4, a pallet assembly 6, an idle positioning mechanism 7 and a lifting and rotating mechanism 8, and the take-up drive Mechanism 4, the idle positioning mechanism 7 and the lifting and rotating mechanism 8 are all installed on the frame 1, the lifting and rotating mechanism 8 is located between the take-up drive mechanism 4 and the idle positioning mechanism 7, and the take-up drive mechanism 4 is equipped with an anti-skid assembly 11, the pallet assembly 6 is installed on the lifting and rotating mechanism 8, and the pallet assembly 6 is processed with avoidance at the positions corresponding to the take-up drive mechanism 4 and the idle positioning mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com