Winding device for uniformly winding enameled wire

A winding device, enameled wire technology, applied in the directions of transportation and packaging, transportation of filamentous materials, thin material handling, etc., can solve the problems of disordered wire, affecting the use of wire, and uneven winding of wire, and achieve orderly winding. , Improve the utilization of storage space, the effect of not easy to stagger and knot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

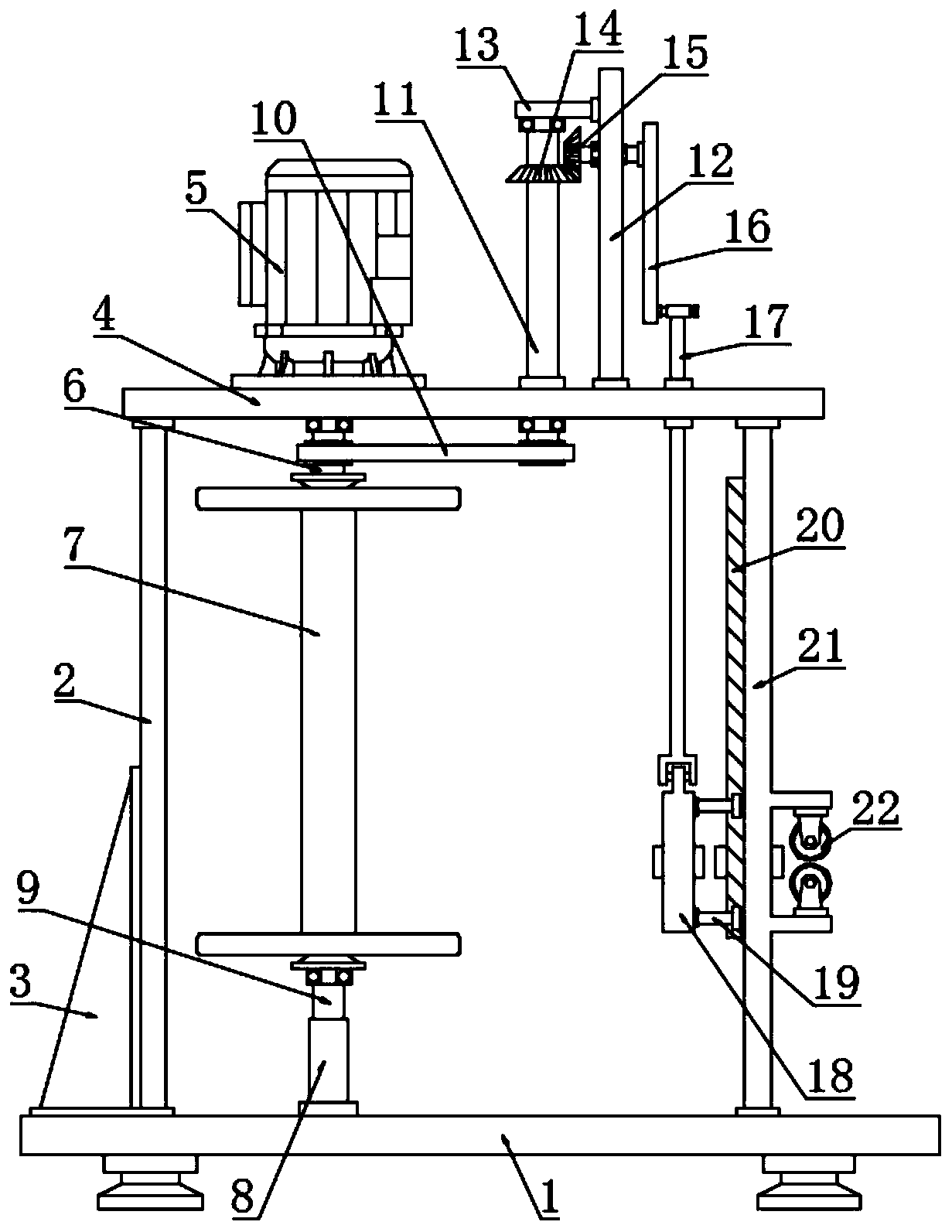

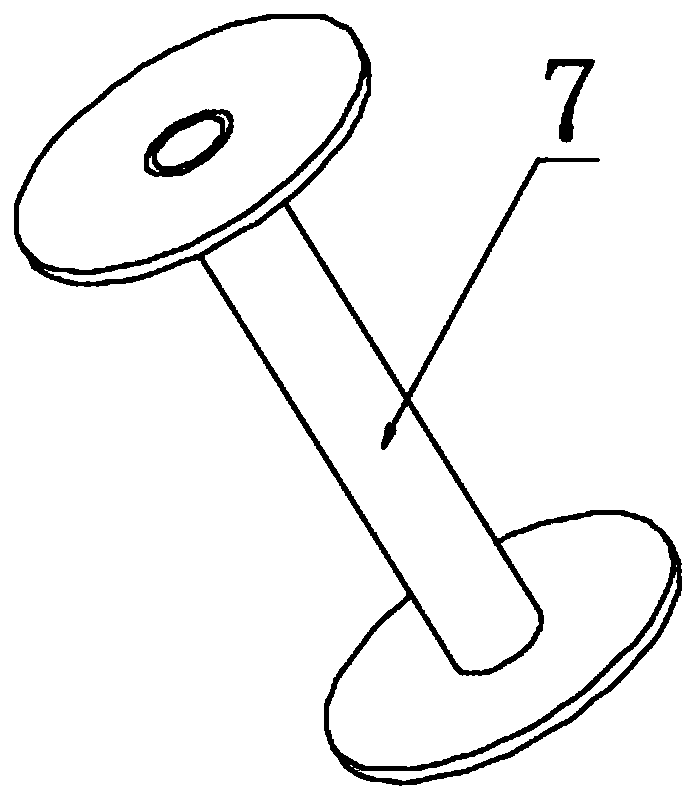

[0023] see Figure 1~3 , in an embodiment of the present invention, a winding device for uniform winding of enameled wire, including a supporting plate 1, a mounting plate 4, a wire roller 7, an eccentric disc 16 and a movable plate 18; the two sides above the supporting plate 1 are respectively fixed There are side boards 2 and fixing boards 21, the underside of the side boards 2 is fixed to the supporting board 1 through the ribs 3, the upper ends of the side boards 2 and the fixing board 21 are fixed through the mounting board 4, and the top of the mounting board 4 is fixedly connected to the driving motor 5 through the flange, and the driving The lower part of the motor 5 is rotatably connected with an output shaft 6, the output shaft 6 passes through the mounting plate 4 and is rotatably connected with the bearing, the drive motor 5 leads are connected to the power supply and the switch, and the switch is turned on so that the drive motor 5 is energized to drive the output...

Embodiment 2

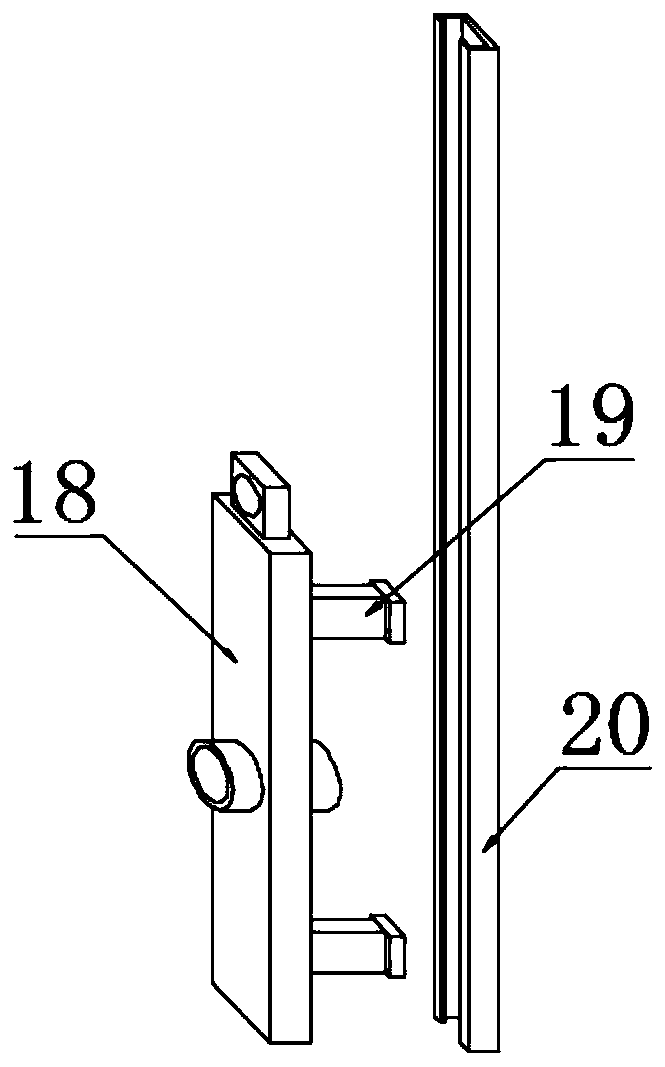

[0026] In order to further explain the above-mentioned winding device for uniform winding of enameled wire, the application provides another embodiment, the winding device for uniform winding of enameled wire in this embodiment has the following technical features: the fixed plate 21 The upper and lower parts of the outer edge of the fixed conduit are provided with straightening wheels 22, and the straightening wheels 22 are rotatably connected with the fixed plate 21. Preferably, the straightening wheels 22 are made of rubber material, and the four corners below the supporting plate 1 are fixedly connected with supporting legs. , the enameled wire passing through the conduit is straightened through the straightening wheels 22 located at the upper and lower parts of the conduit, and the straightening wheel made of rubber has a certain degree of elasticity to prevent damage to the enameled wire.

[0027] According to the specific description of the above embodiment, it is easy t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com