Rotary piezoelectric driving device based on asymmetric triangular hinge mechanism

A hinge mechanism, piezoelectric drive technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of output load reduction, small pre-tightening force, piezoelectric The rigidity of the components is not fully utilized to achieve the effect of increasing the output load, high working efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

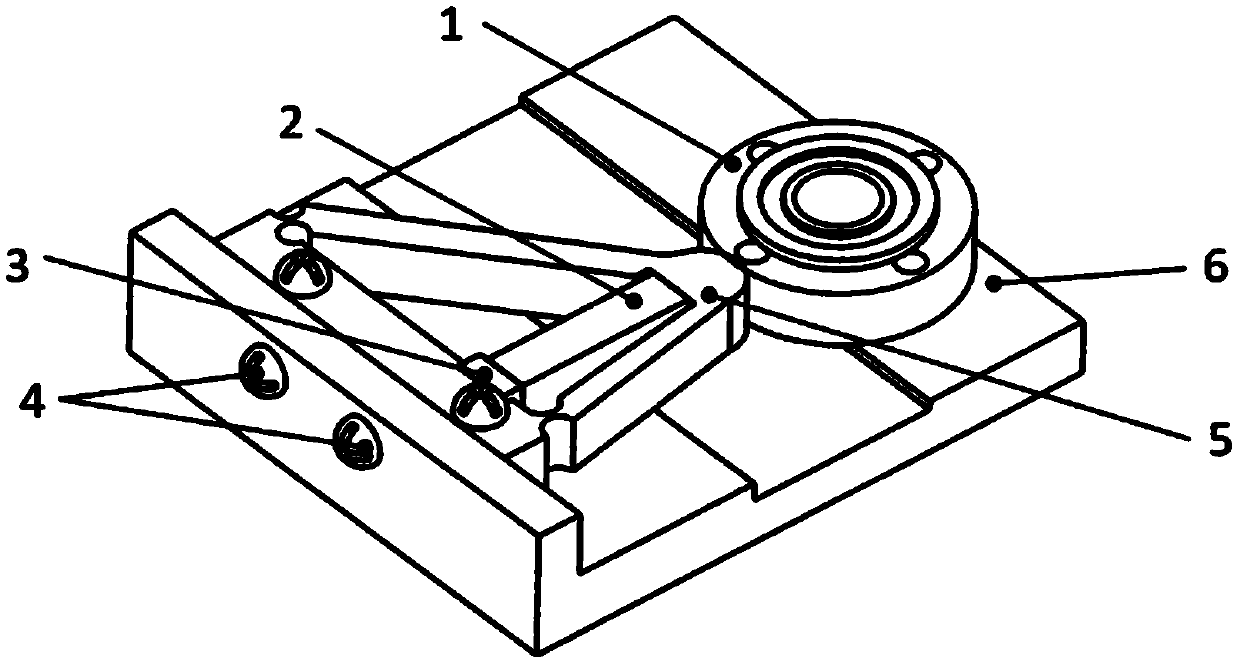

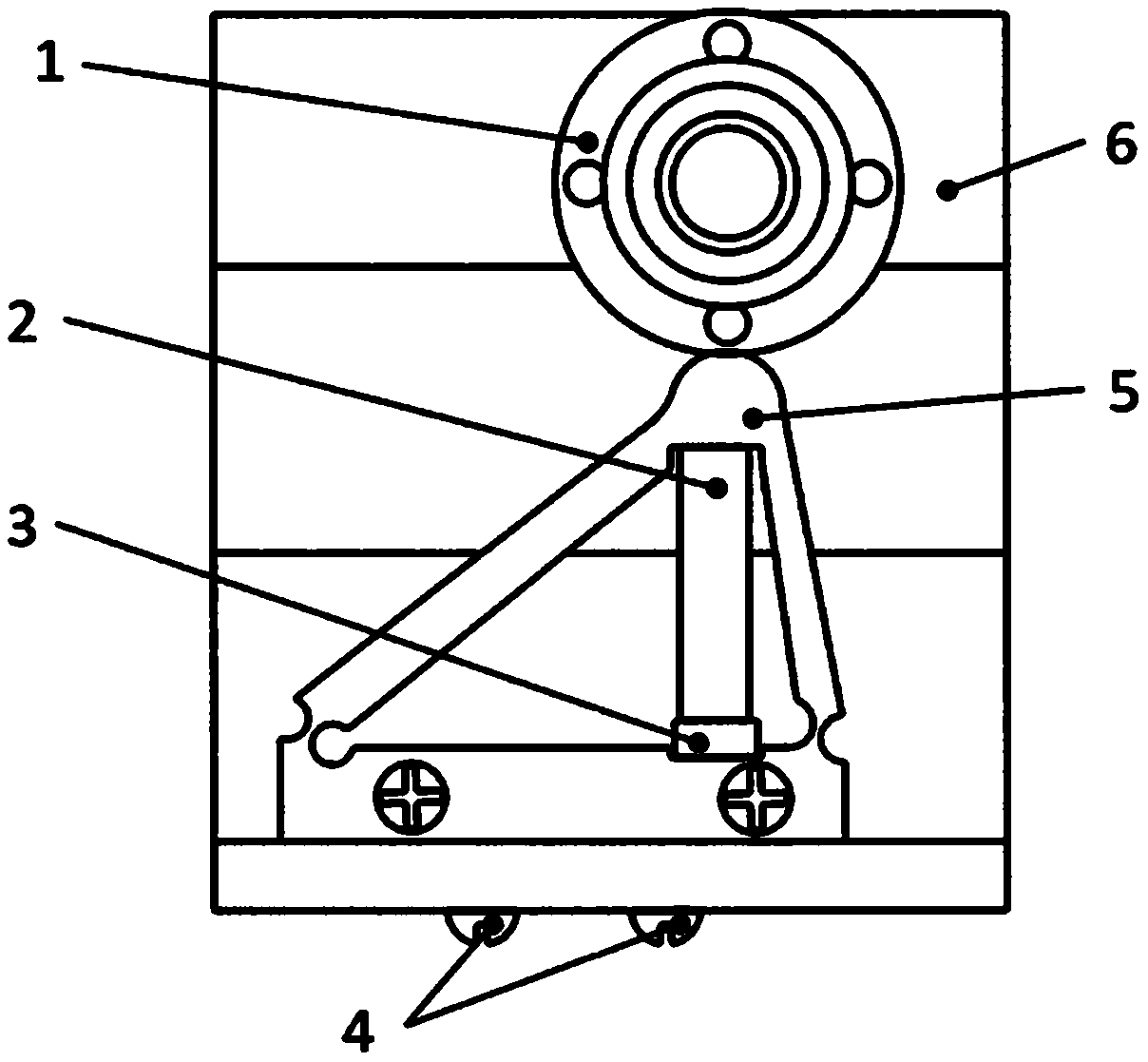

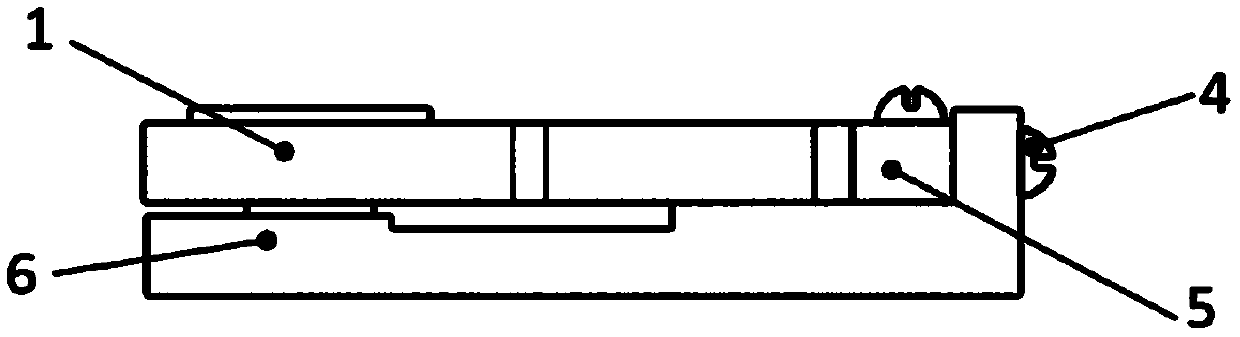

[0020] see Figure 1 to Figure 4 As shown, a rotary piezoelectric drive device based on an asymmetrical triangular hinge mechanism mainly includes a rotor (1), a piezoelectric stack (2), a pre-tightening wedge (3), a pre-tightening screw (4), non- A symmetrical triangular hinge mechanism (5) and a base (6), the driving device realizes precise driving of piezoelectric rotation through the principle of parasitic inertia. The rotor (1) includes a rotary table, a bearing, and a rotary shaft. The rotary table and the outer ring of the bearing, the rotary shaft and the inner ring of the bearing, and the rotary shaft and the base are interference fits; the structure of the rotor (1) uses high-precision bearings to reduce the Its friction loss, the bearing is connected with the base through the rotating shaft; the asymme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com