Harmonic reducer with composite ball bearing and lower shell manufacturing method

A technology of harmonic reducer and compound ball, which is used in manufacturing tools, components with teeth, belts/chains/gears, etc., can solve the problems of small contact bearing area, easy damage and deformation of flexible bearings, etc., to achieve output The effect of increasing the load, prolonging the service time, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

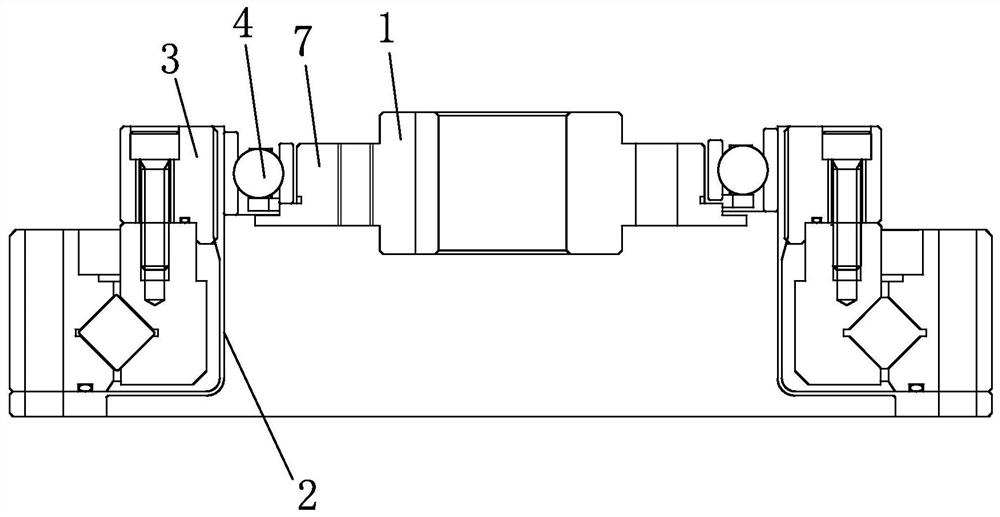

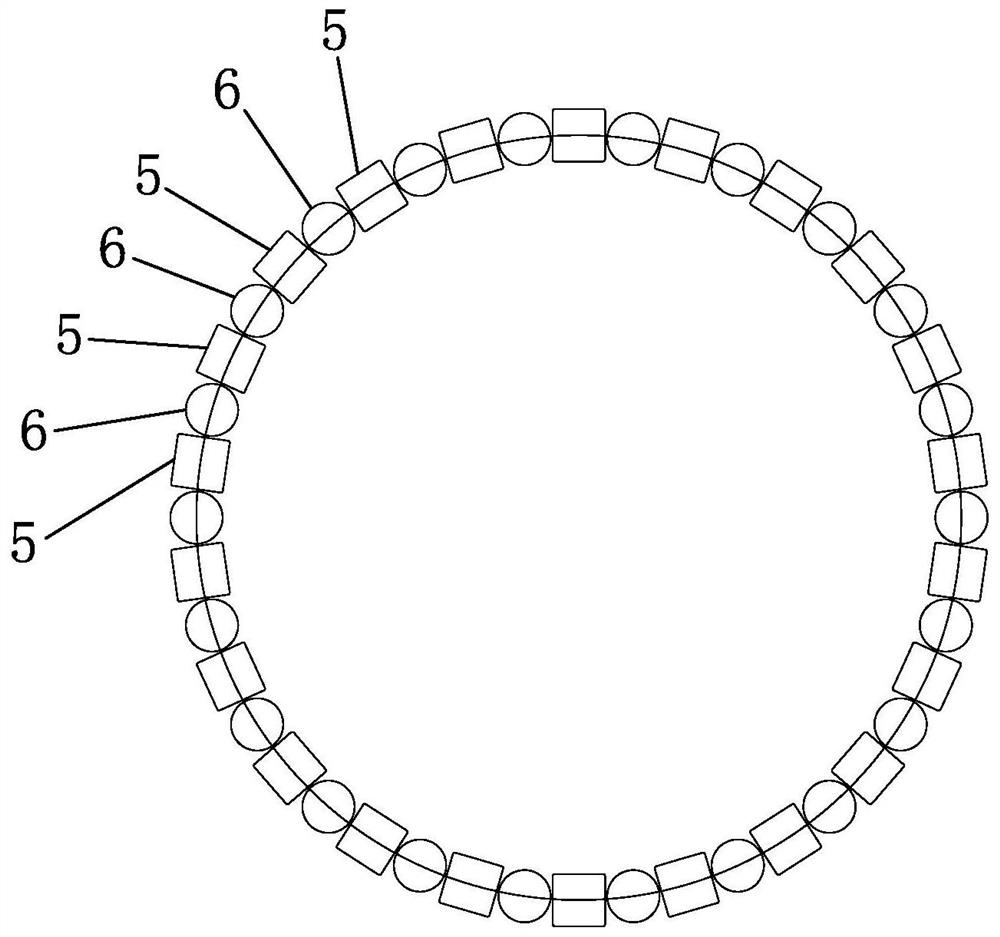

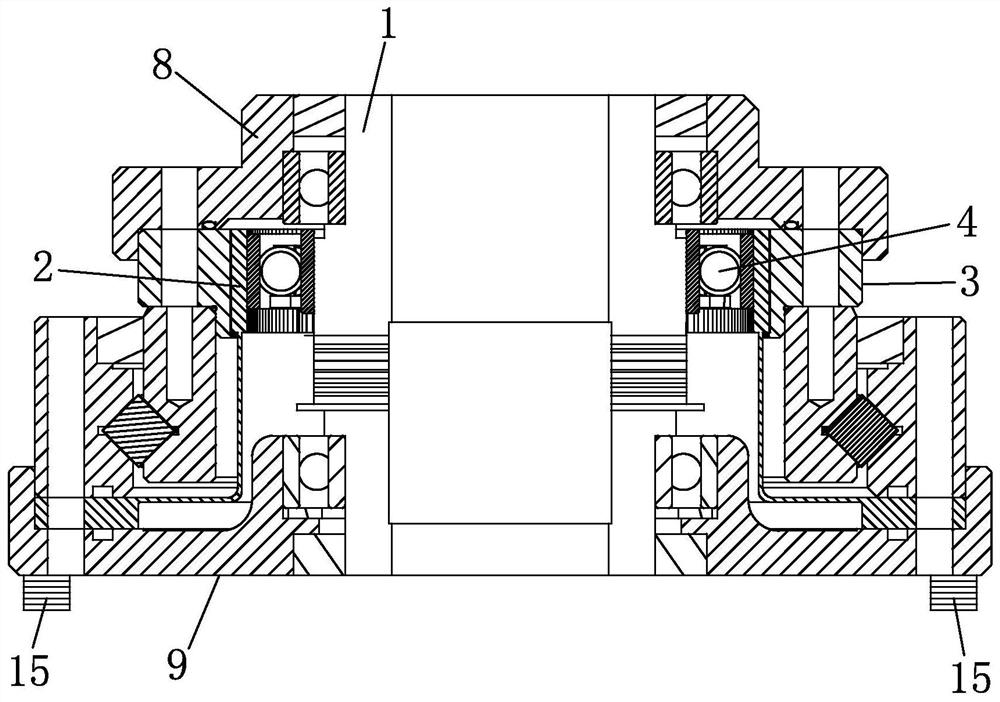

[0050] A harmonic reducer with composite ball bearings, including a wave generator 1, a flex spline 2 and a rigid spline 3, the wave generator 1 is built in the internal installation cavity of the flex spline 2, the wave generator 1 includes an input shaft end and cam7. A composite ball bearing 4 is arranged between the outer peripheral surface of the cam 7 and the inner peripheral surface of the flexible spline 2. The composite ball bearing 4 includes an inner ring and an outer ring, and a roller installation cavity is arranged between the inner ring and the outer ring. and a ball installation cavity, the roller installation cavity is provided with a roller 5, and the ball installation cavity is provided with a ball 6. It is equipped with a composite ball bearing 4, and the roller 5 and the ball 6 are used in combination, so that the composite ball bearing 4 can bear a greater load during the transmission process, which is suitable for high-speed and low-speed use scenarios a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com