Three-dimensional circulating conveying line type dense container system

A three-dimensional circulation and line technology, applied in the directions of transportation, packaging, storage devices, etc., can solve the problems of large working space requirements, complex driving process, low volume loading rate, etc., and achieve high driving reliability, high volume loading rate, Simple drive structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. It should be noted that, in the case of no conflict, the embodiments and the features in the embodiments of the present invention can be combined with each other, and the described embodiments are only some of the embodiments of the present invention, but not all of the embodiments.

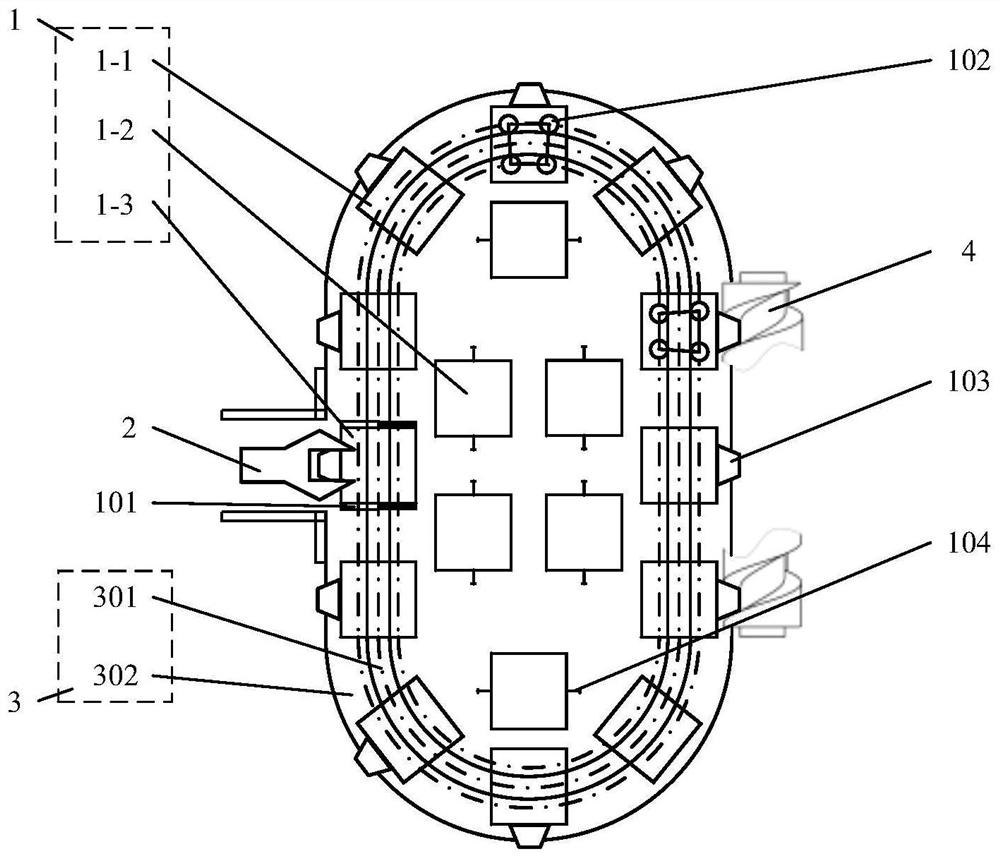

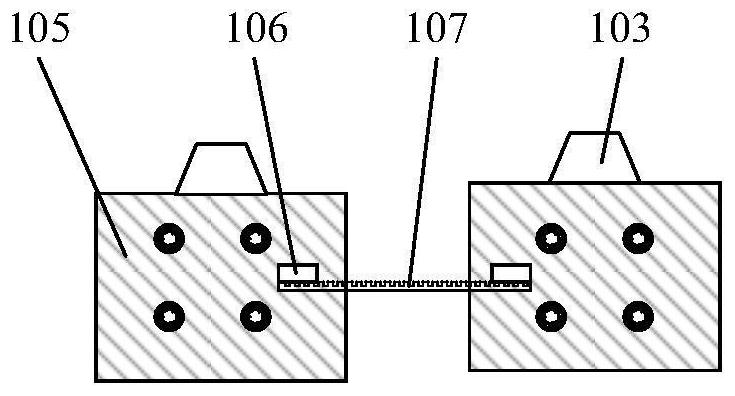

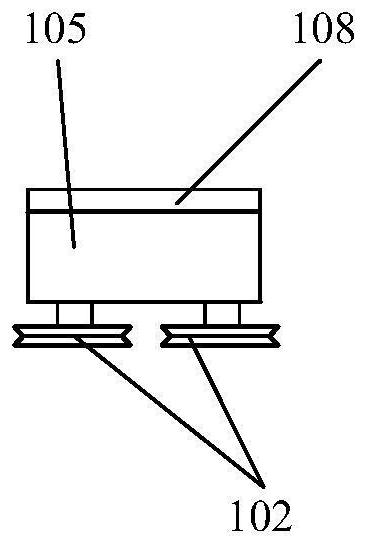

[0025] see Figure 1-4 Description of this embodiment, a three-dimensional circulating conveyor line-type dense container system, which includes a material conversion mechanism, the material conversion mechanism includes a loading platform 1, a mechanical claw mechanism 2, a material circulation track system 3 and a drive screw mechanism 4, and the loading platform 1 Including multiple mobile loading platforms 1-1, multiple fixed loading platforms 1-2 and empty platforms 1-3, multiple mobile loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com