Real-time fault identification and reconstruction system and method for hall sensor of brushless direct current motor

A brushless DC motor and Hall sensor technology is applied to the real-time fault identification, reconstruction and fault protection of the Hall signal of the brushless DC motor, and the field of the real-time fault identification and reconstruction system of the brushless DC motor Hall sensor, which can solve the problem of the Hall sensor of the brushless DC motor. Abnormal Hall signal output, failure of the whole machine, instantaneous interruption of Hall signal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

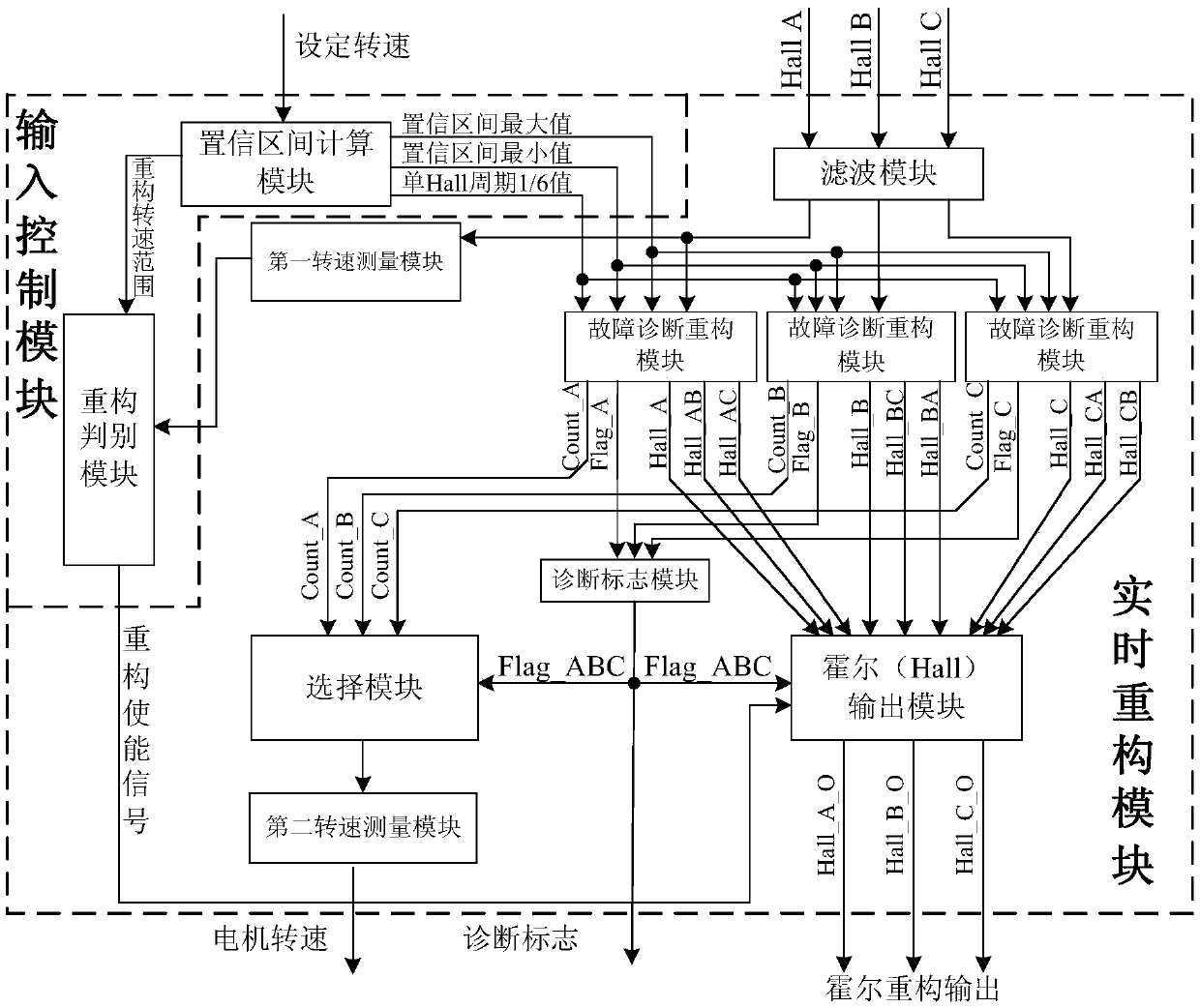

[0060] Such as figure 1 As shown, a brushless DC motor Hall sensor real-time fault identification and reconstruction system, the system includes an input control module and a real-time Hall reconstruction module;

[0061] The input control module includes a confidence interval calculation module and a reconstruction discrimination module;

[0062] The real-time Hall reconstruction module includes a filter module, a fault diagnosis reconstruction module, a diagnosis flag module, a selection module, a first rotational speed measurement module, a second rotational speed measurement module and a Hall output module.

[0063] A brushless DC motor Hall sensor real-time fault identification and reconstruction method, the steps of the method include:

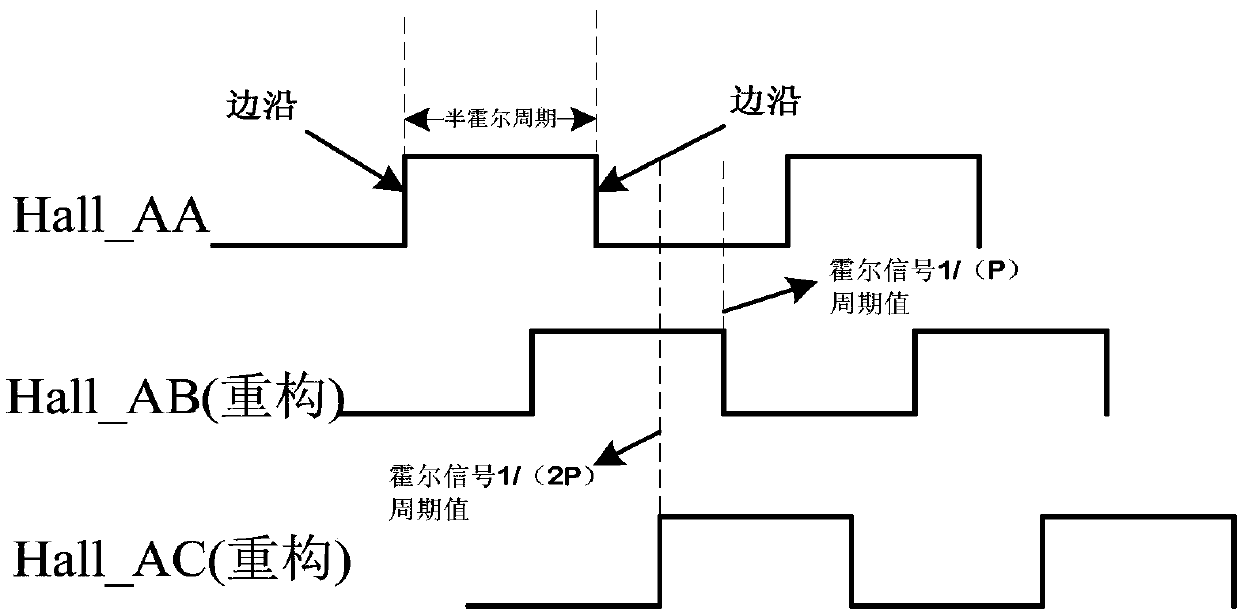

[0064] (1) Set the speed of the brushless DC motor, and use the set speed of the brushless DC motor as the input of the confidence interval calculation module. The confidence interval calculation module calculates three values accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com