Rotatory test temperature measuring equipment of aircraft engine rotor part

A technology of aero-engine and rotation test, applied in measuring devices, components using electrical devices, thermometers, etc., can solve problems such as cylinder drive mechanism failure, poor cylinder drive reliability, failure, etc., to achieve convenient installation location and drive reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

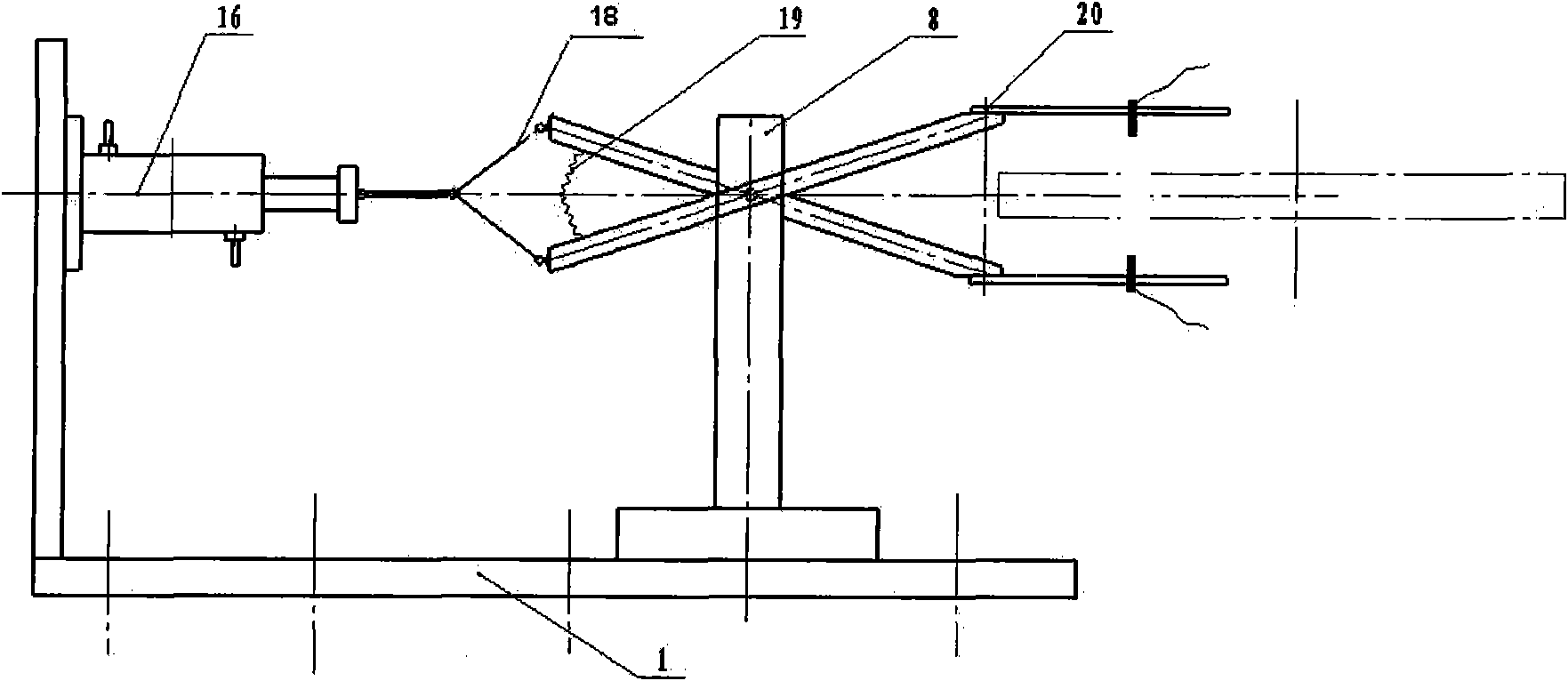

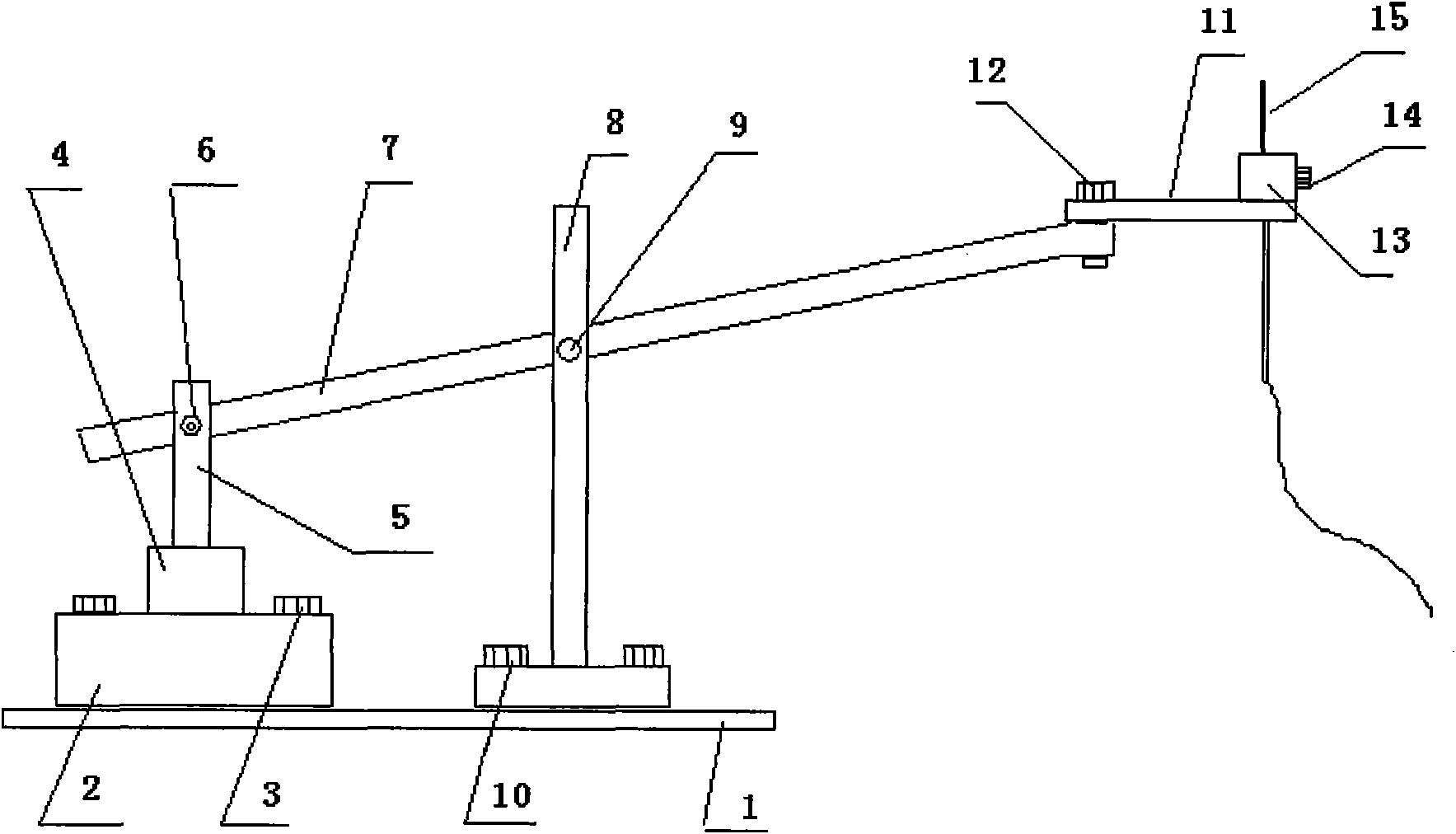

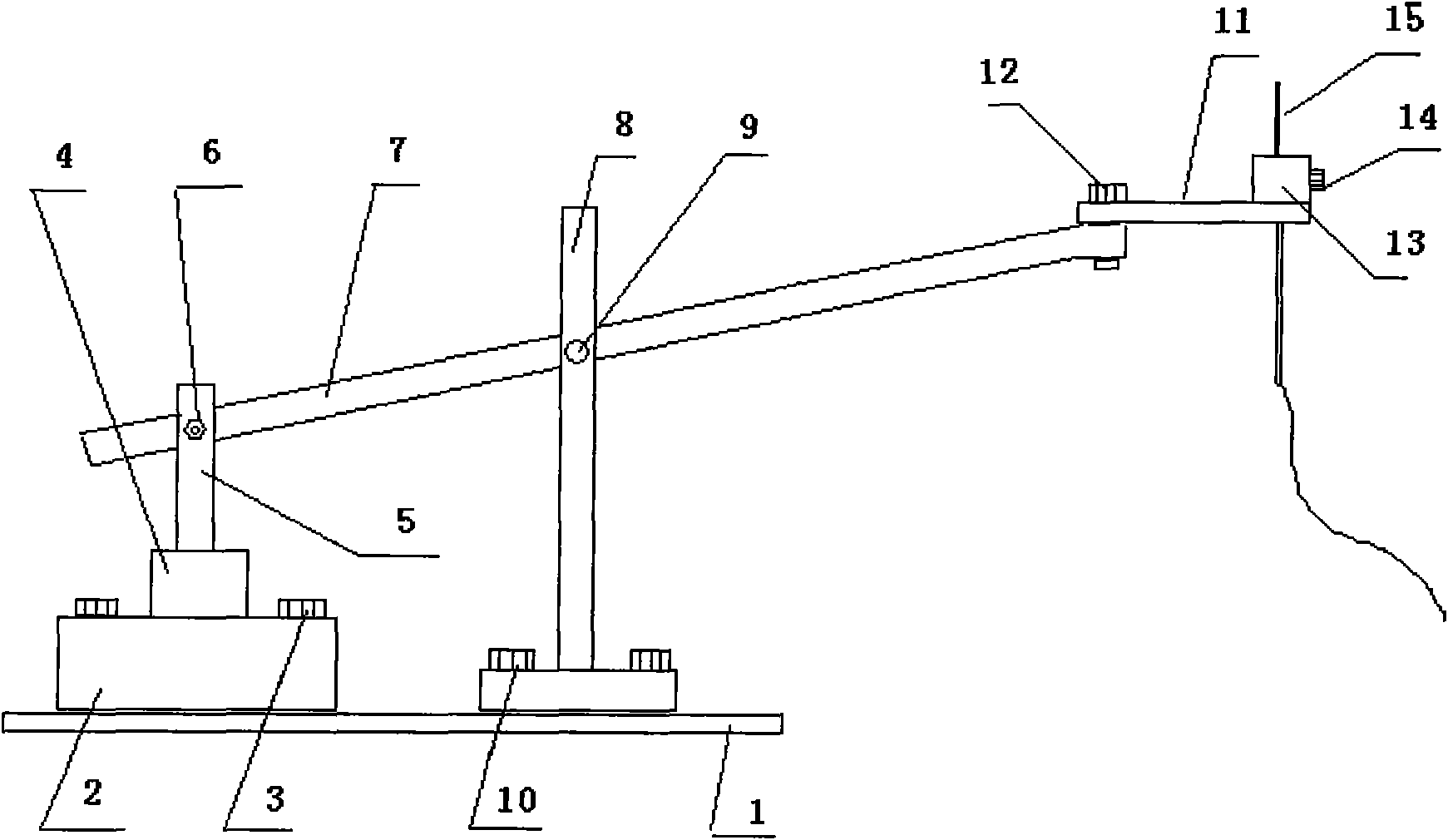

[0008] The present invention will be described in further detail below. see figure 2 , aero-engine rotor component rotation test temperature measuring device, including base plate 1, lever bracket 8 and thermocouple assembly, the base of lever bracket 8 is fixed on base plate 1 by lever bracket fixing screw 10, and there is a horizontal lever bracket on lever bracket 8 Shaft hole, lever shaft 9 is arranged in this lever bracket shaft hole.

[0009] The thermocouple assembly is made up of thermocouple holder 13, set screw 14 and thermocouple 15, and thermocouple 15 is passed in the thermocouple installation hole of thermocouple holder 13, and thermocouple 15 is locked by set screw 14.

[0010] It is characterized in that there is a single-arm lever mechanism composed of an electromagnet drive mechanism, a connecting rod hinge shaft 6, a lever 7, a thermocouple assembly mounting plate 11 and a connecting screw 12. There is a horizontal lever shaft hole in the middle part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com