Winding method for multiple radial parallel winding layer distribution transformer coils

A technology of distribution transformers and winding methods, which is applied in the direction of inductance/transformer/magnet manufacturing, circuits, electrical components, etc., can solve the problems of adding silicon steel sheets and using more copper, and achieve the reduction of coil height, small space, and shortened axial direction The effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

[0022] The winding method of the multi-layered distribution transformer coil radially provided by the present invention comprises the following steps:

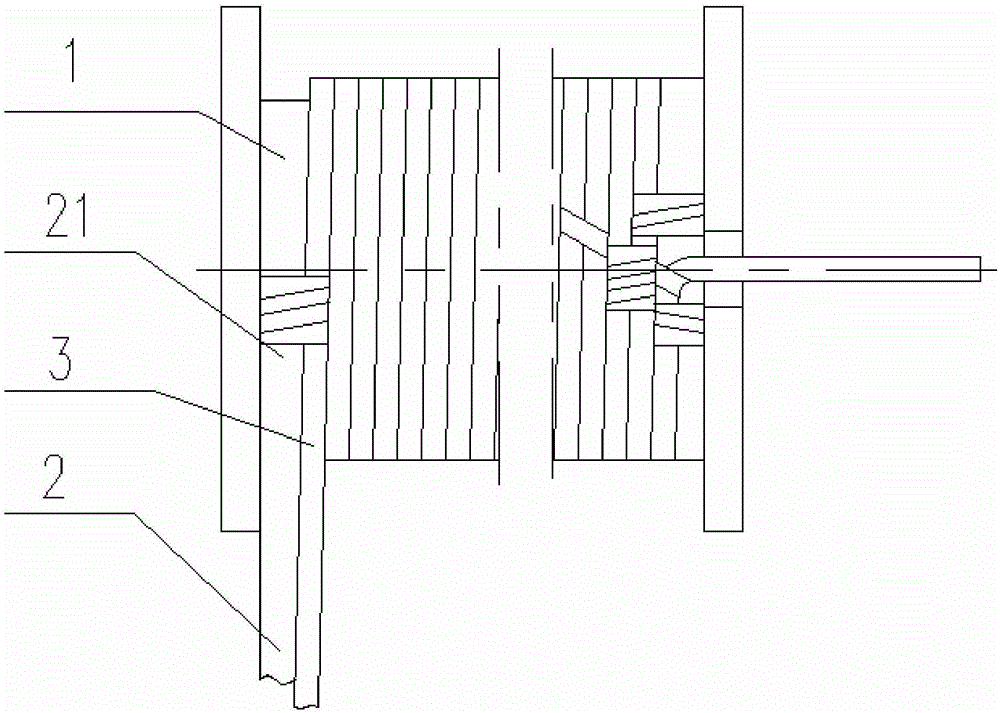

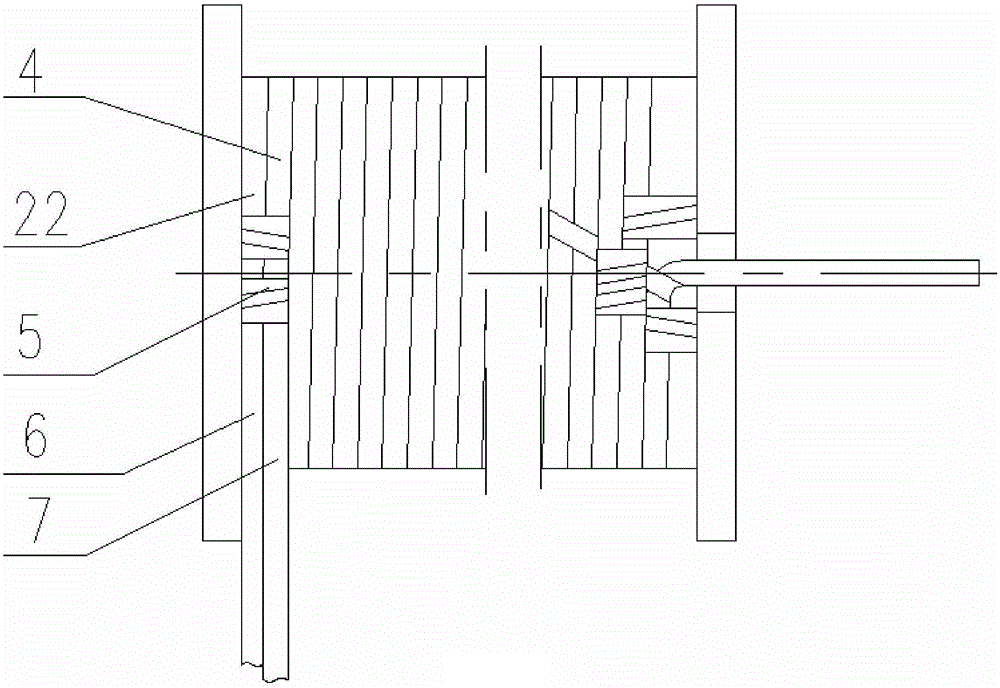

[0023] (1) Wind the first layer of coils from the beginning to the end on the winding mold 1. At the beginning of the penultimate turn 3 of the first layer, bind the wedge-shaped end insulation 2 whose height difference between the large end and the small end is the height of the coil. The big head 21 of the end insulation is bound and fixed to the beginning of the penultimate turn of the first layer, and then the wire and the wedge-shaped end are insulated and wound side by side to complete the last turn 4 of the first layer, as shown in figure 1 and figure 2 shown;

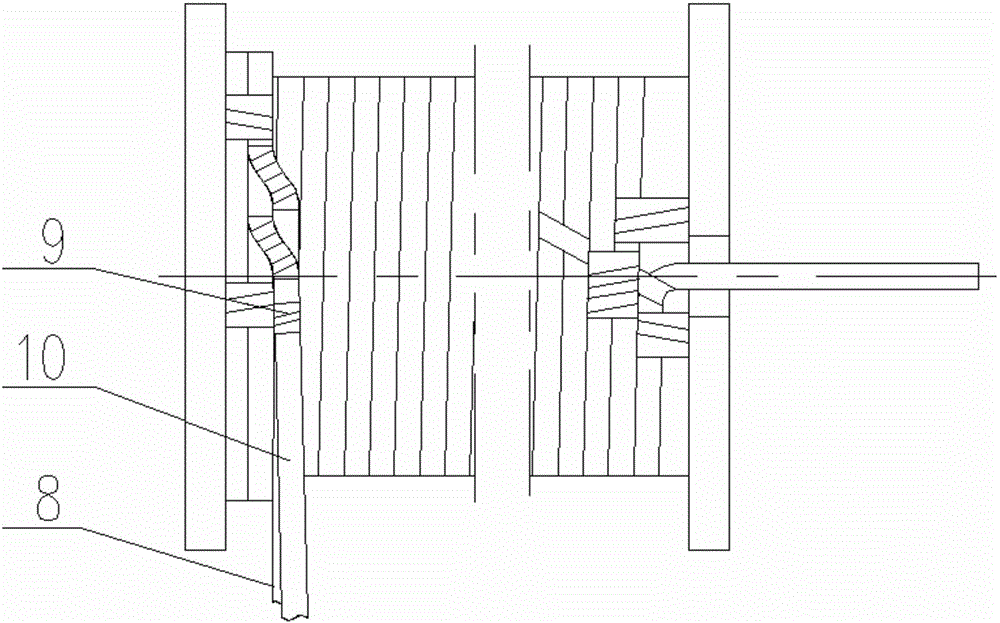

[0024] (2) After the coil is lifted, bind the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com