Automatic stainless steel tube winding and packaging mechanism

A stainless steel tube and automatic technology, applied in packaging, conveyor belt wrapping, etc., can solve the problems of inability to achieve uniformity and consistency, be easily affected by workers' emotions, and affect the quality of product packaging, so as to reduce labor force and automate The effect of high degree and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

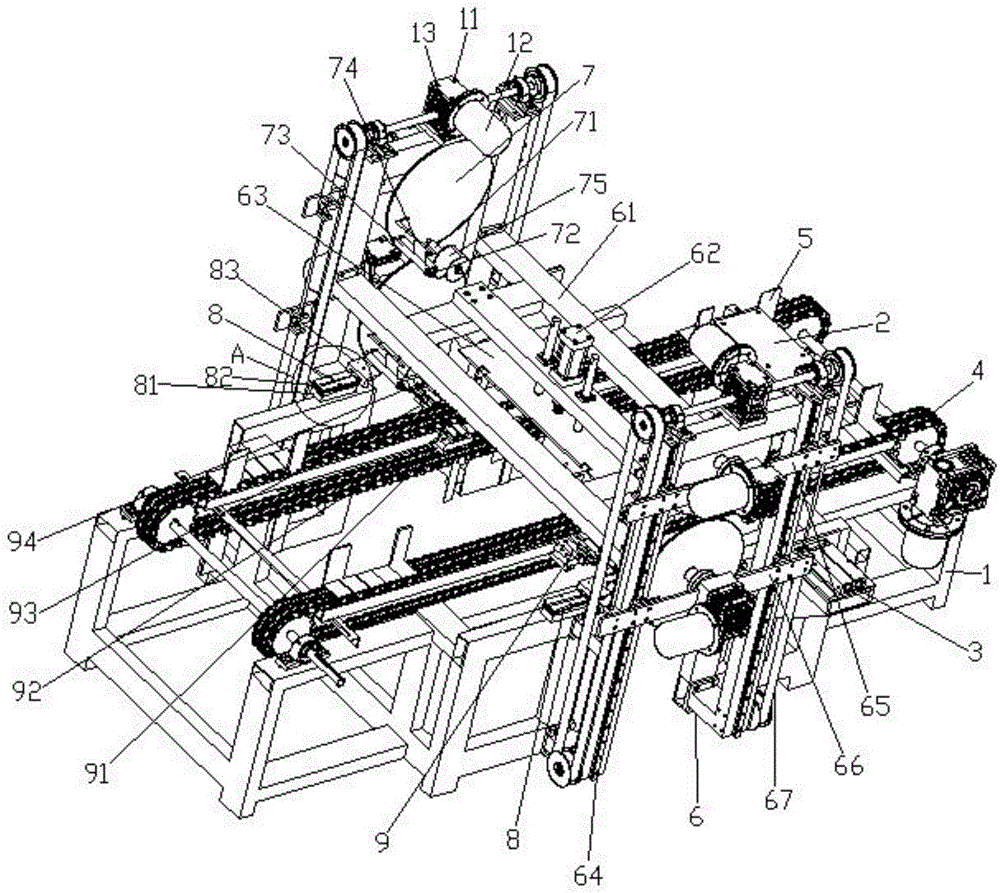

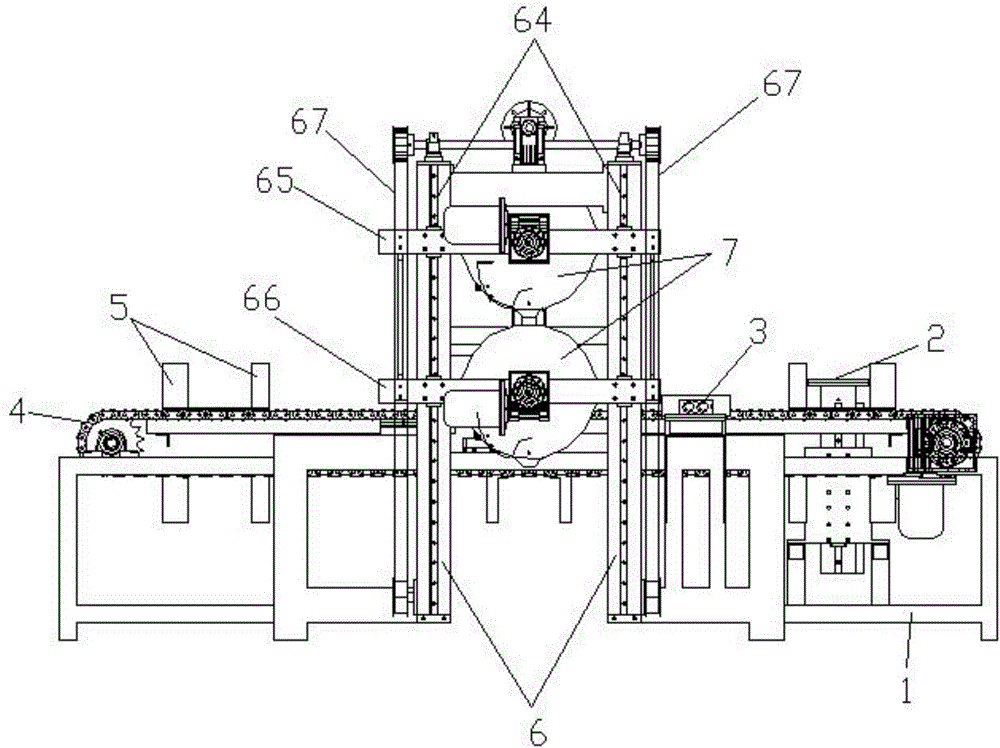

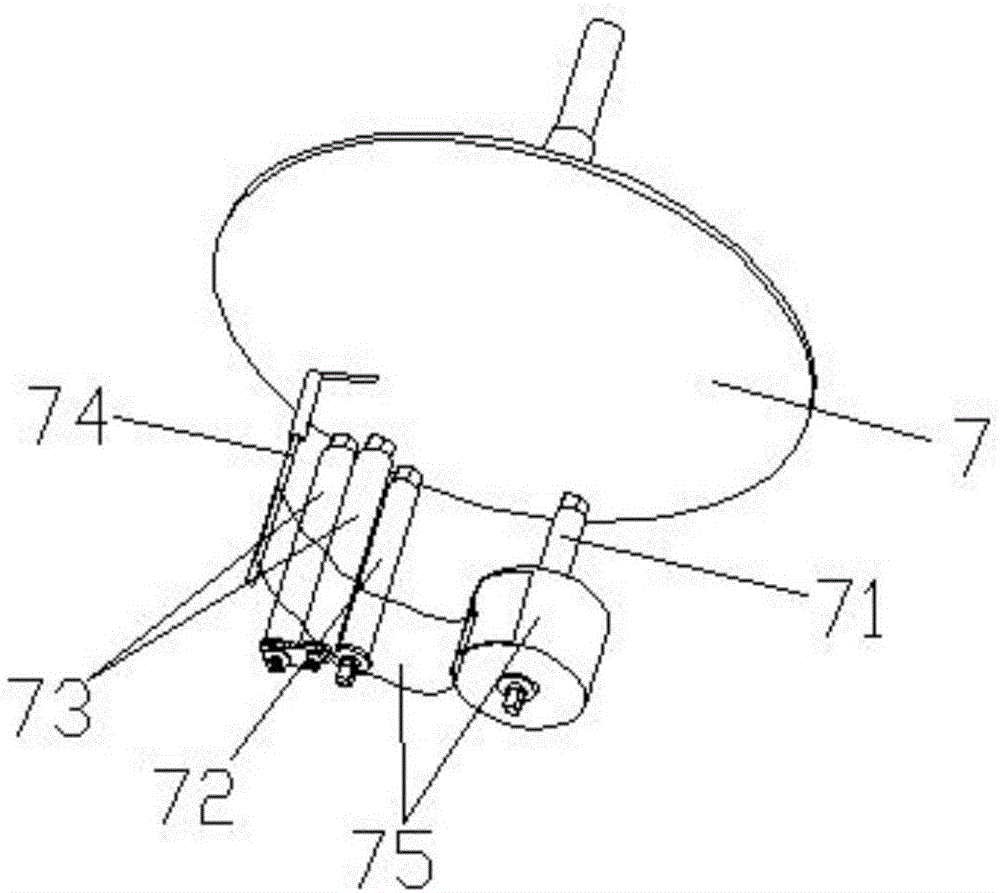

[0019] Such as figure 1 The automatic winding and packaging mechanism for stainless steel tubes shown includes a machine base 1, a stacking mechanism 2, an alignment mechanism 3 and a chain conveyor line 4. Placed in the middle of the blocking column 5, the machine base 1 is equipped with a stainless steel tube automatic winding packaging mechanism, the stainless steel tube automatic winding packaging mechanism includes a winding bracket 6 installed on the machine base 1, and the winding bracket 6 is installed with the following Press the fixed bracket 61, and the fixed bracket 61 is equipped with a first cylinder 62. The front end of the first cylinder 62 is equipped with a pressing plate 63, which can press and fix the stainless steel tube layer. A linear guide rail 64 is installed on the winding bracket 6. On the 64, an upper movable seat plate 65 and a lower movable seat plate 66 are installed, and the movable seat plate 65 and the lower movable seat plate 66 are driven by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com