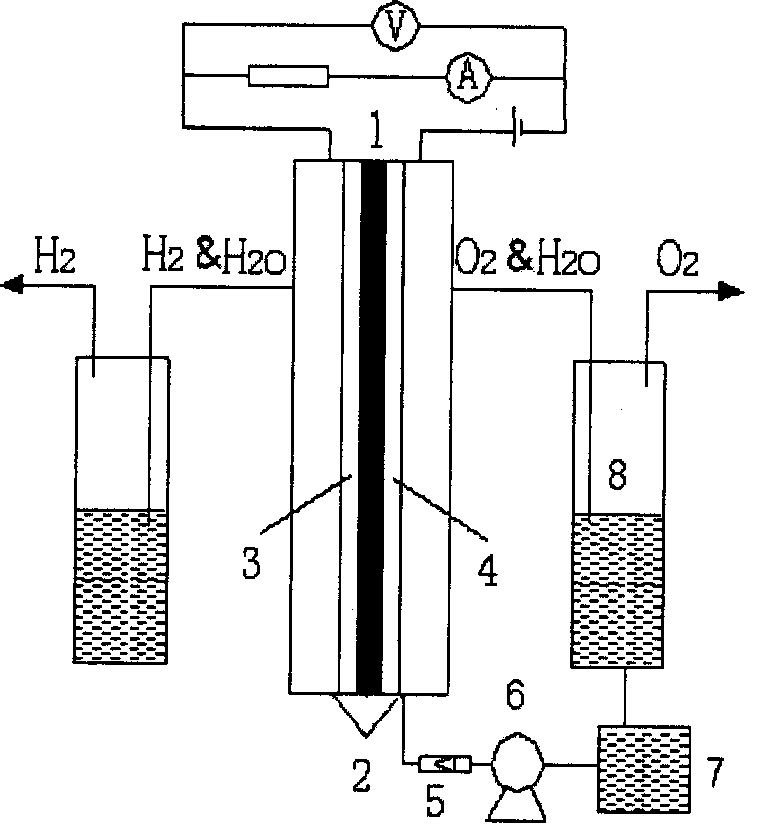

Preparation method of film electrode for solid polymer electrolyte water electrolysis

A solid polymer, electrolyte water technology, applied in the electrolysis process, electrolysis components, cells and other directions, can solve the problems of unsuitability for commercial production, reduce the thickness of the catalytic layer, complex process, etc., achieve easy commercial production, simple equipment, Simple way to make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

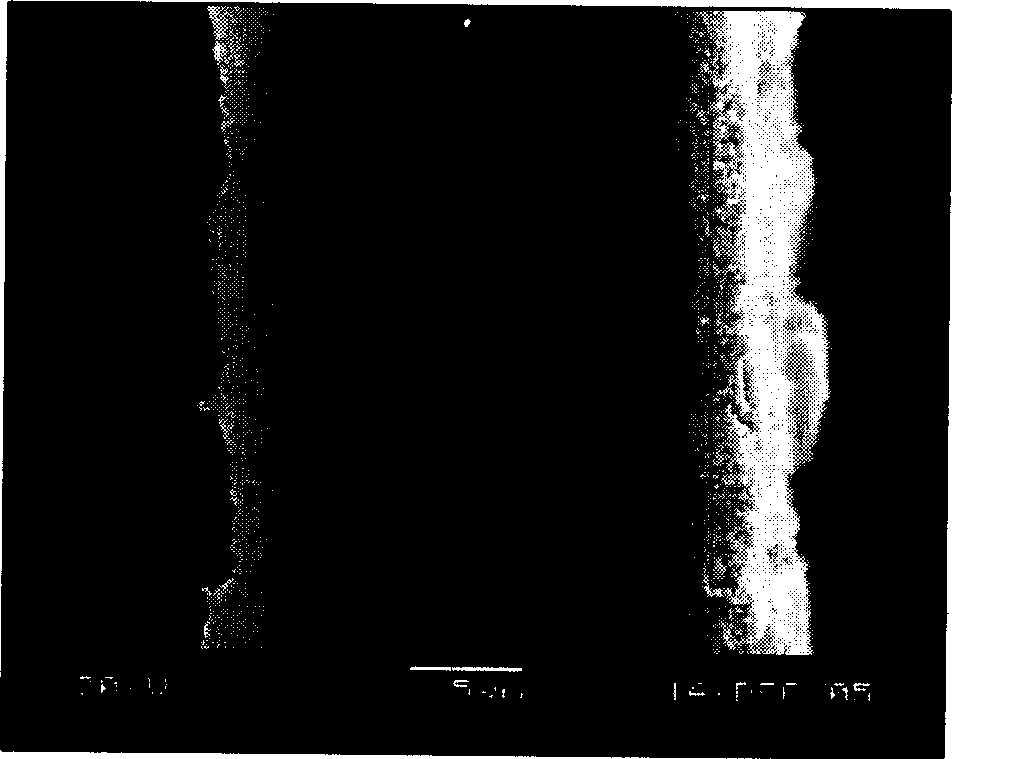

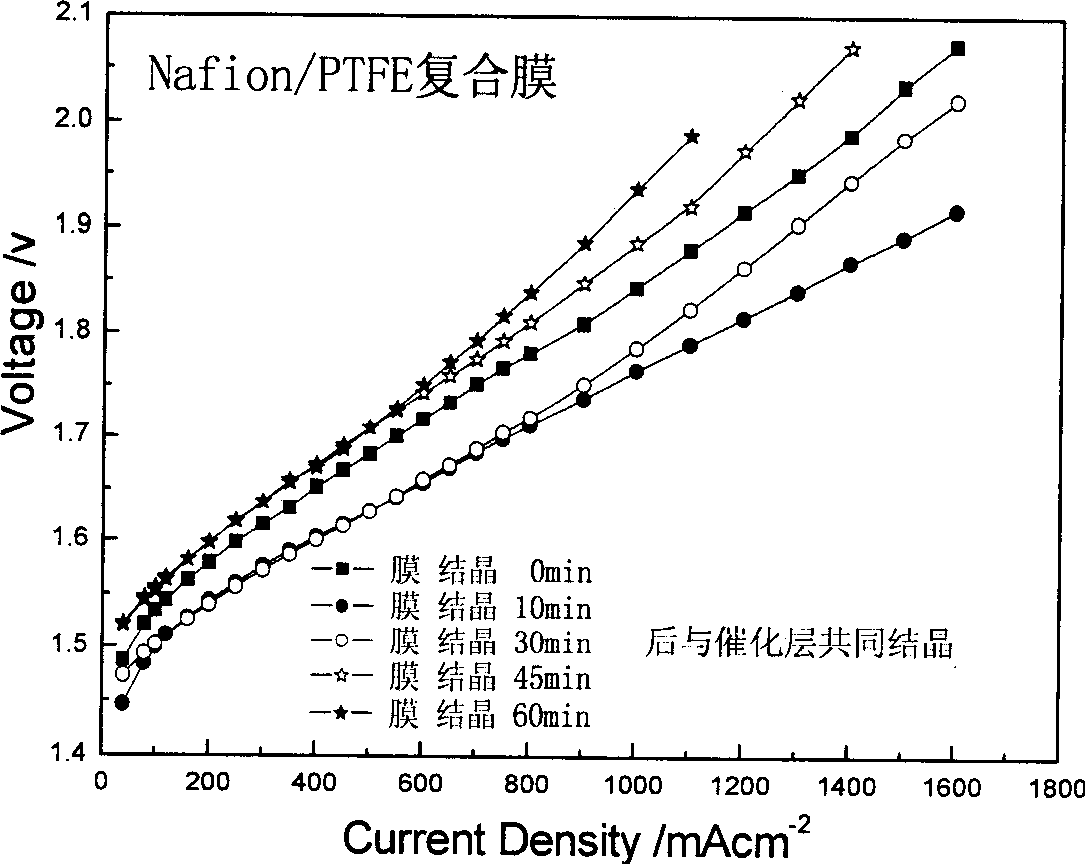

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: take by weighing 5% Nafion (EW=1100g / mol SO3H ) solution, add 10ml of N-methyl-2-pyrrolidone, seal and heat to dissolve, and make a solid polymer electrolyte solution.

Embodiment 2

[0036] Embodiment 2: take by weighing Nafion (EW=1000g / mol SO3H ) 1 gram of resin, add 10ml of N-methyl-2-pyrrolidone and isopropanol, seal and heat to dissolve, and make a solid polymer electrolyte solution.

Embodiment 3

[0037] Example 3: Weigh 2 grams of sulfonated polyetheretherketone (sulfonation degree: 70%), add 10 ml of dimethyl sulfoxide and 5 ml of acetone, seal and heat to dissolve, and prepare a solid polymer electrolyte solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com