C/SiC coating with pore structure and preparation method thereof

A technology of pore structure and coating, applied in the field of C/SiC coating containing pore structure and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

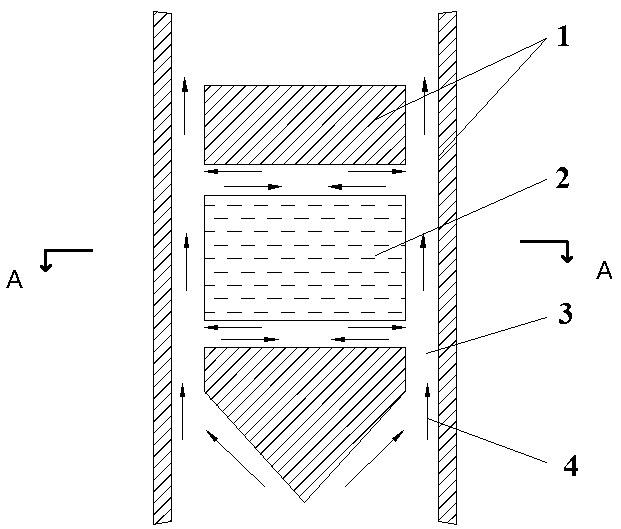

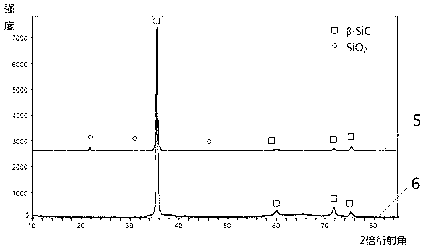

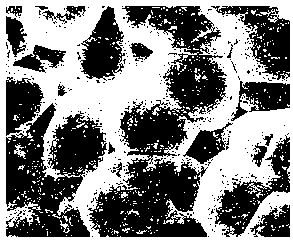

[0032] Example 1: see figure 1 , figure 2 and Figure 10 . The temperature in the constant temperature zone of the deposition chamber in the thermal furnace is 1150°C, the pressure in the furnace is 1kpa, MTS and H 2 The purity of the gas is ≥99%; the flow rate of MTS is determined by the carrier gas H 2 flow control, H 2 The flow rate is 0.3L / min; while diluting gas H 2 The flow rate is 0.6L / min, and the slit width of the "slit-type" deposition chamber is designed to be 2mm. "Slit" deposition chamber see figure 1 and Figure 10 , C / SiC coating phase composition see figure 2 , C / SiC coating surface morphology of C / C composite materials and graphite materials, see respectively image 3 and 4 .

Embodiment 2

[0033] Example 2: see figure 1 , figure 2 and Figure 10 . The temperature in the constant temperature zone of the deposition chamber in the thermal furnace is 1300°C, the pressure in the furnace is 5kpa, MTS and H 2The purity of the gas is ≥99%; the flow rate of MTS is determined by the carrier gas H 2 flow control, H 2 The flow rate is 0.3L / min; while diluting gas H 2 The flow rate is 0.6L / min, and the slit width of the "slit-type" deposition chamber is designed to be 5mm. "Slit" deposition chamber see figure 1 and Figure 10 , C / SiC coating phase composition see figure 2 , C / SiC coating surface morphology of C / C composite materials and graphite materials, see respectively image 3 and 4 .

Embodiment 3

[0034] Embodiment 3: see figure 1 , figure 2 and Figure 10 . The temperature in the constant temperature zone of the deposition chamber in the thermal furnace is 1200°C, the pressure in the furnace is 10kpa, MTS and H 2 The purity of the gas is ≥99%; the flow rate of MTS is determined by the carrier gas H 2 flow control, H 2 The flow rate is 0.4L / min; while diluting gas H 2 The flow rate is 0.9L / min, and the slit width of the "slit-type" deposition chamber is designed to be 8mm. "Slit" deposition chamber see figure 1 and Figure 10 , C / SiC coating phase composition see figure 2 , C / SiC coating surface morphology of C / C composite materials and graphite materials, see respectively image 3 and 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com