All-solid mixed-potential NOx sensor and preparation method thereof

A mixed-potential, full-curing technology, applied in instruments, scientific instruments, material analysis by electromagnetic means, etc., can solve the problem that the reduction reaction speed of the catalytic active electrode surface of the sensitive electrode is reduced, the electrolyte and the sensitive electrode are easily peeled off, and the sensor is affected. Detection sensitivity and other problems, to achieve the effect of shortening the sintering cycle, high density, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

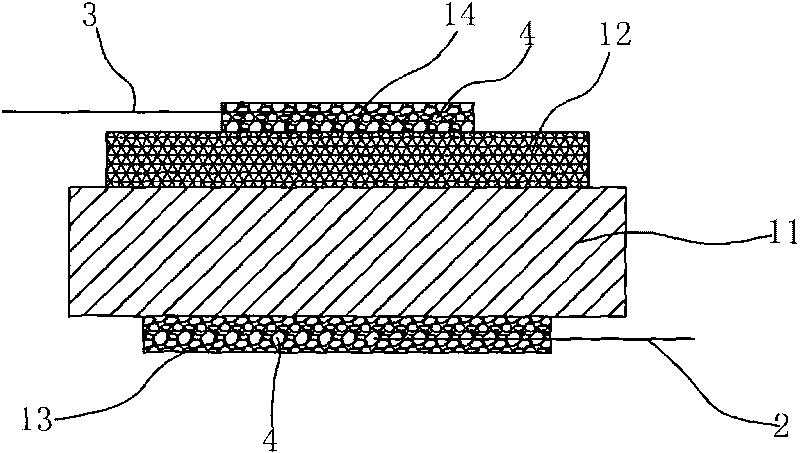

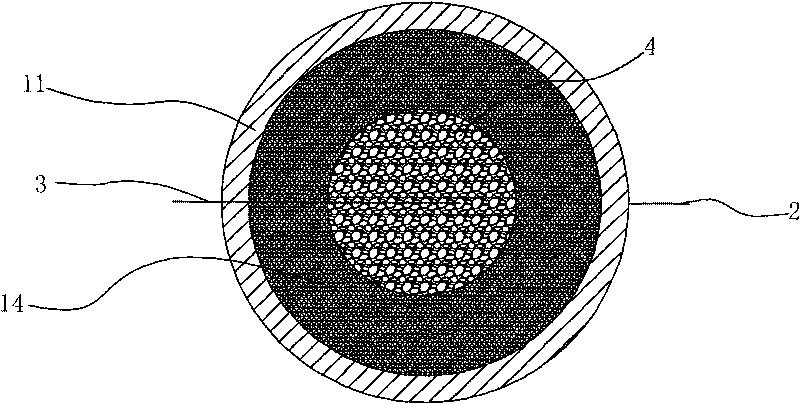

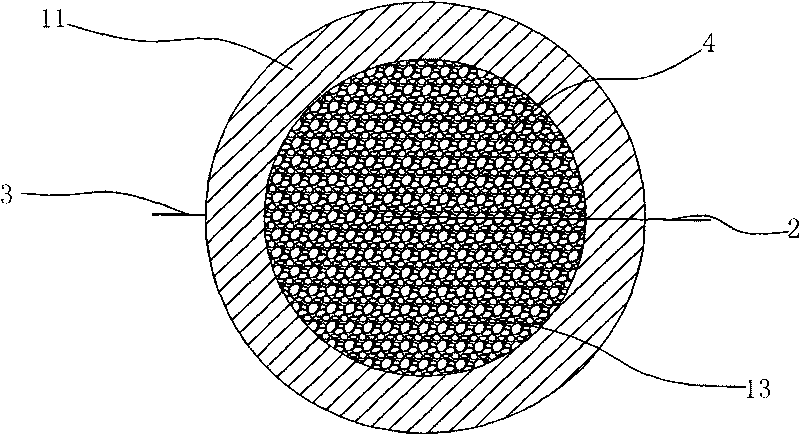

[0030] Such as Figure 1 to Figure 6 As shown in the figure, the electrolyte layer 11; the sensitive electrode layer 12; the reference electrode 13; the working electrode 14; the first lead 2; the second lead 3;

[0031] Such as Figure 1 to Figure 4 As shown, the present invention is a fully solidified mixed potential NOx sensor, which mainly includes an electrolyte layer 11, a sensitive electrode layer 12, a reference electrode 13, and a working electrode 14. One side of the electrolyte layer 11 is provided with a sensitive electrode layer 12, and the electrolyte layer One side of 11 and the inner surface of the sensitive electrode layer 12 are sintered together by spark plasma sintering technology, where the spark plas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com