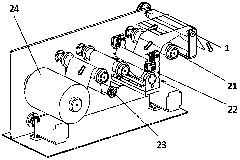

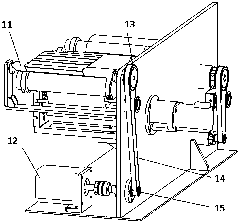

Stripping device and stripping method of multilayer flexible film

A flexible film, peeling device technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of lack of peeling ends, reduced peeling efficiency, poor peeling effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

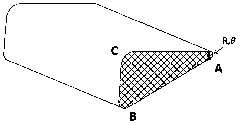

[0053] The inventors of the present application have found that whether the label is peeled off depends on the interfacial energy between the label and the carrier tape. and the bending potential energy G of the label Inlay Relationship. The interface energy forms the bonding force between the label and the carrier tape, and makes the label bend along with the carrier tape, that is, the greater the interface energy, the less likely the label will be peeled off; the bending potential energy refers to the rigidity of the label itself to keep the label straight, The effect of not following the bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com