A longitudinal-torsional compound vibration processing system applied to processing hard and brittle materials

A technology of compound vibration and hard and brittle materials, which is applied in the field of longitudinal and torsional compound vibration processing systems, can solve problems such as failure to report the processing quality of hard and brittle materials, inability to coordinate processing as a whole, and inability to control the processing progress, etc., to achieve material quality protection , easy to realize, and improve the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

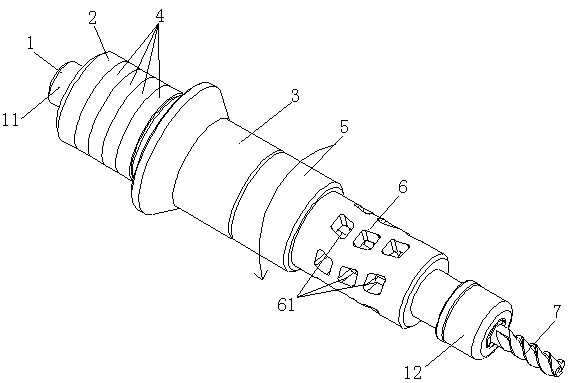

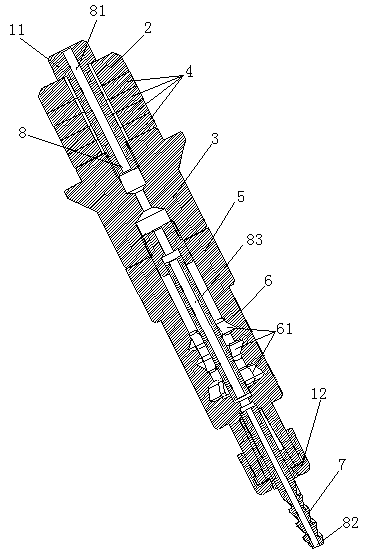

[0032] A longitudinal-torsion composite vibration processing system applied to the processing of hard and brittle materials. The vibration processing system is mainly composed of an ultrasonic generator, a longitudinal-torsion composite vibration device, a hard and brittle workpiece, and a processing and testing device. The ultrasonic generator is mainly Including ultrasonic generator, longitudinal vibration ultrasonic transducer and ultrasonic wireless transmission control system, the ultrasonic energy output and energy conversion output system are formed through the logical connection of electric signals;

[0033]The longitudinal-torsion compound vibration device is driven and connected with the ultrasonic generating device, and mainly includes a locking structure 1, a front end cover 2, a rear end cover 3, a piezoelectric ceramic sheet 4, a torque actuator 5, a longitudinal-torsion compound conversion structure 6, a hollow The cutting tool 7 and the cooling system 8, wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com