Semiconductor device

A semiconductor and flip-chip technology, which is applied in semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve problems such as stripping of heat sinks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

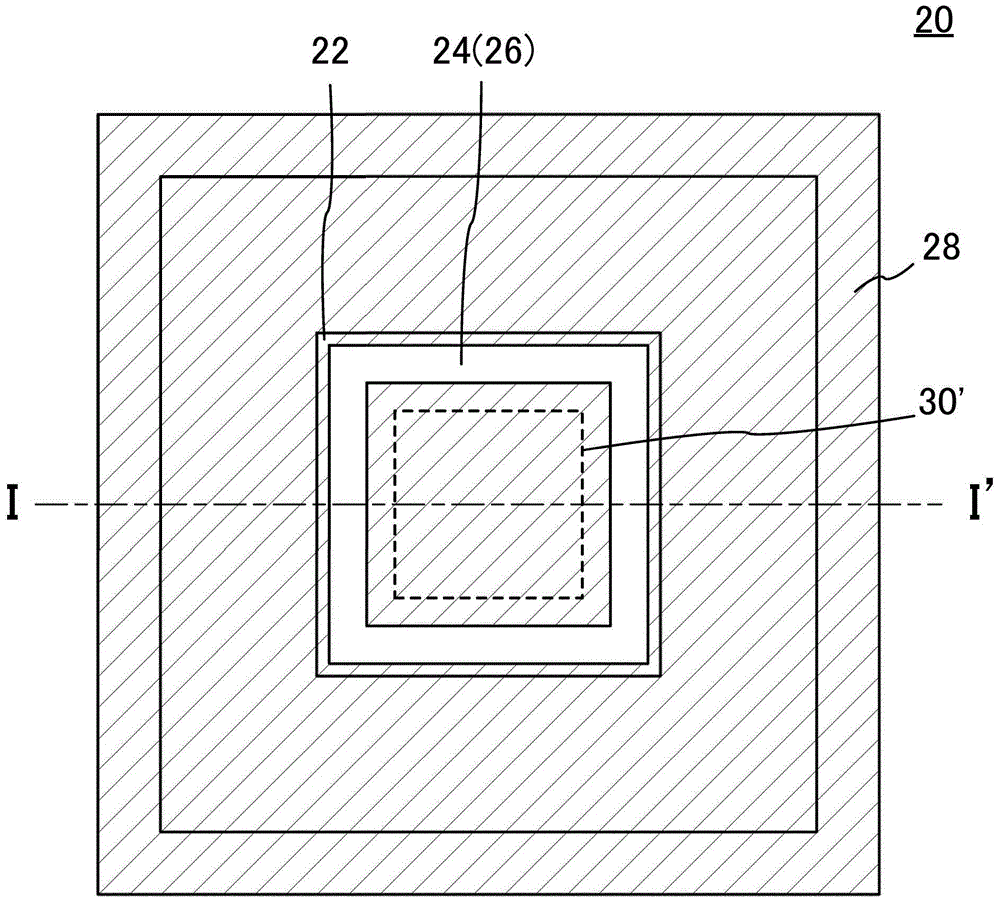

[0035] use figure 1 Referring to FIG. 3 , the structure of the semiconductor device according to Embodiment 1 will be described.

[0036] [Overall structure of semiconductor device]

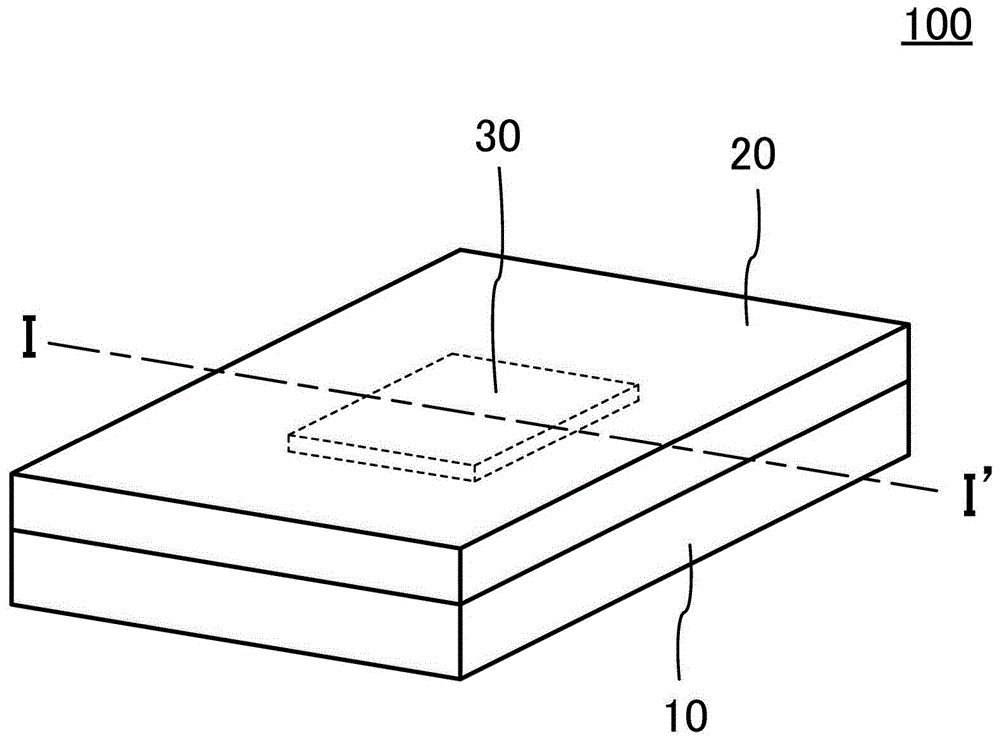

[0037] figure 1 It is a schematic diagram showing the overall structure of the semiconductor device 100 according to the first embodiment of the present invention. In the semiconductor device 100 , a semiconductor chip 30 is arranged on a substrate 10 , and a heat sink 20 is arranged on the substrate 10 and the semiconductor chip 30 . The substrate 10 and the radiator plate 20 are disposed opposite to each other, and both have substantially the same area, and the semiconductor device 100 has a substantially cubic shape.

[0038] [Cross-sectional view of a semiconductor device]

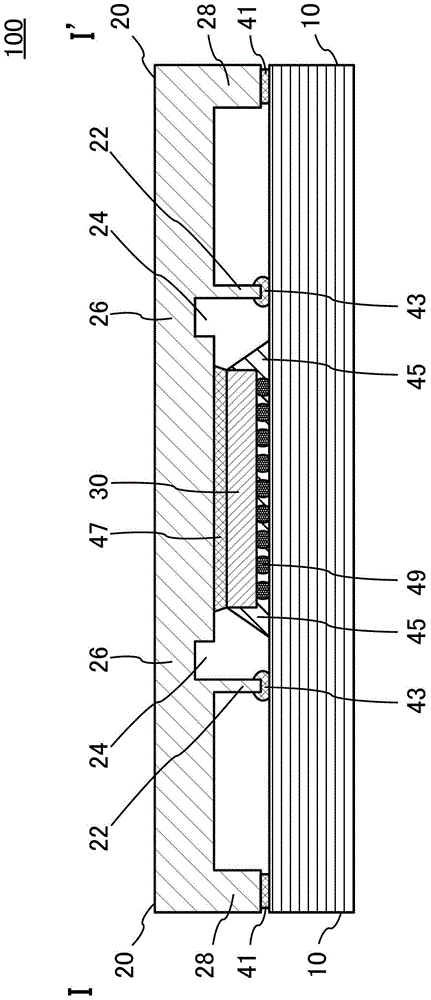

[0039] figure 2 To show the edge of the semiconductor device 100 according to the first embodiment of the present invention figure 1 The cross-sectional view of the line I-I'.

[0040] The substrate 10 is a packag...

no. 2 approach

[0052] For an overview of the semiconductor device according to the second embodiment of the present invention, refer to Figure 4A and Figure 4B to explain.

[0053] Figure 4A It is a plan view of the heat sink 20 of the semiconductor device of the second embodiment, Figure 4B for along Figure 4A The cross-sectional view of the II-I' line in . The second embodiment is characterized in that two grooves, ie, groove 24 a and groove 24 b are arranged in heat dissipation plate 20 , and stress absorbing portion 26 is formed. The groove 24a and the groove 24b are formed between the region 30' where the semiconductor chip 30 is bonded and the protrusion 22. As with the groove 24 of the first embodiment, it is preferable that the groove 24 a be arranged close to the position where the protrusion 22 is arranged. More preferably, the groove 24a is arranged adjacent to the position where the protrusion 22 is arranged. In addition, like the groove 24 of the first embodiment, th...

no. 3 approach

[0056] For an overview of the semiconductor device according to the third embodiment of the present invention, refer to Figure 5A and Figure 5B to explain.

[0057] Figure 5A It is a plan view of the heat sink 20 of the semiconductor device of the third embodiment, Figure 5B for along Figure 5A The cross-sectional view of the II-I' line in . The third embodiment is characterized in that a bottom hole 24 c is arranged in the radiator plate 20 to form a stress absorbing portion 26 . The bottomed hole 24c is formed between the region 30' where the semiconductor chip 30 is bonded and the protrusion 22. Preferably, the bottomed hole 24c is disposed near the position where the protruding portion 22 is disposed. More preferably, the bottomed hole 24c is arranged adjacent to the position where the protrusion 22 is arranged. refer to Figure 5A It can be seen that the plurality of bottomed holes 24c are arranged at predetermined intervals along the protrusion 22 and arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com