Lithium ion secondary battery electrolyte

A secondary battery and electrolyte technology, applied in secondary batteries, organic electrolytes, non-aqueous electrolytes, etc., can solve problems such as graphite peeling, achieve the effect of improving initial discharge capacity and solving graphite peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

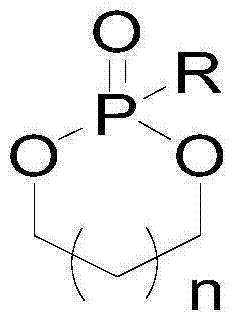

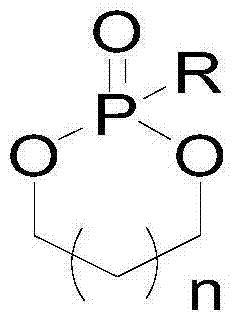

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of the positive electrode sheet is as follows: lithium cobaltate, conductive agent SuperP, and binder PVDF are mixed uniformly at a mass ratio of 96:2.0:2.0 to make a lithium ion secondary battery positive electrode slurry with a certain viscosity, and coated on the set On fluid aluminum foil, the coating amount is 0.0194g / cm 2 , after drying at 85°C, cold pressing; then trimming, cutting, and slitting, and drying at 85°C for 4 hours under vacuum conditions after slitting, and welding the tabs to make lithium-ion di Secondary battery positive.

[0016] The preparation method of the negative electrode sheet is as follows: graphite, conductive agent SuperP, thickener CMC, and adhesive SBR are made into slurry at a mass ratio of 96.5:1.0:1.0:1.5, coated on the current collector copper foil and placed on the Dried at 85°C, the coating weight is 0.0089g / cm 2 After trimming, cutting, and slitting, dry at 110° C. for 4 hours under vacuum conditions aft...

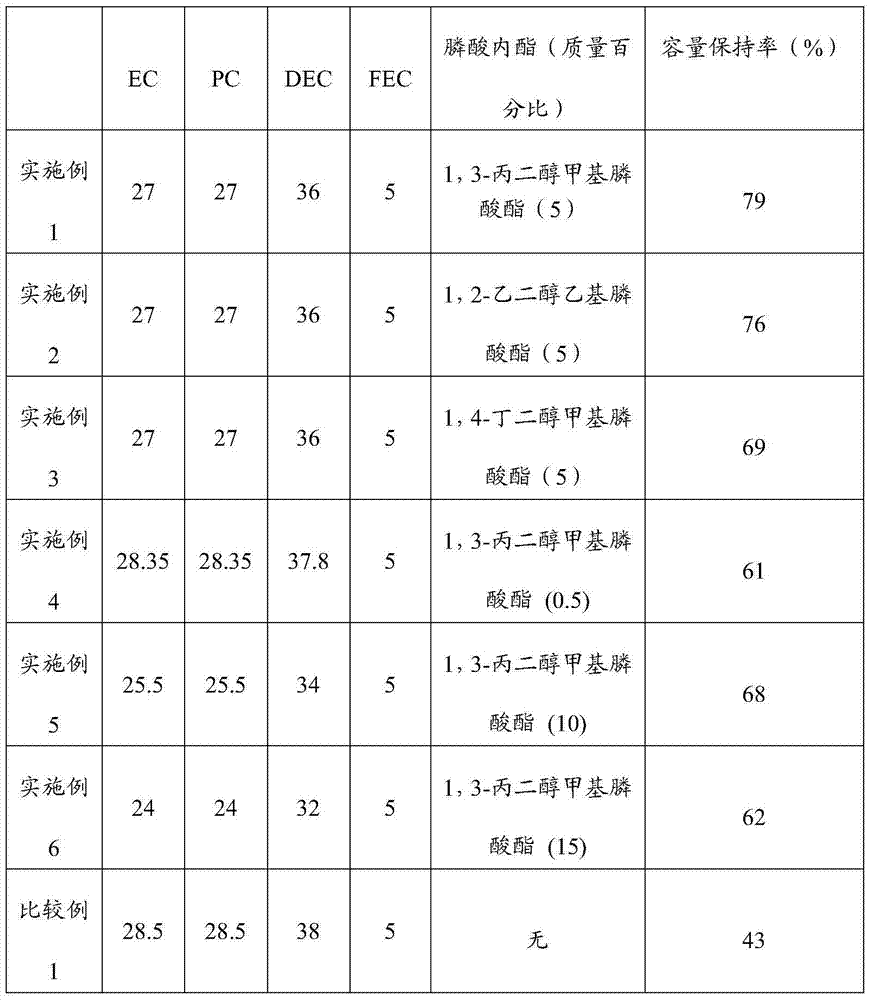

Embodiment 1

[0021] Ethylene carbonate (EC), propylene carbonate (PC), diethyl carbonate (DEC), fluoroethylene carbonate (FEC) (fluoroethylene carbonate is a kind of halogenated cyclic carbonate) and Cyclic phosphonates are mixed according to the mass ratio in Table 1 to obtain an electrolyte solvent, and 1M LiPF is dissolved in the electrolyte solvent 6 That is, a non-aqueous electrolyte solution is obtained.

[0022] Preparation of lithium-ion secondary battery: The positive electrode sheet, negative electrode sheet and separator of the lithium-ion secondary battery prepared according to the aforementioned process are made into a lithium-ion secondary battery with a thickness of 4.2mm, a width of 34mm, and a length of 82mm through a winding process. Batteries were vacuum-baked at 75°C for 10 hours, injected with the above-mentioned non-aqueous electrolyte, and left to stand for 24 hours, then charged to 4.2V with a constant current of 0.1C (160mA), and then charged at a constant voltage ...

Embodiment 2

[0024] Lithium-ion secondary battery was prepared with reference to the method of Example 1, except that when preparing lithium-ion secondary battery electrolyte, 1,2-ethylene glycol ethyl phosphonate was used to replace 1,3-propylene glycol methyl in Example 1 base phosphonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com