Non-water electrolyte for lithium ion battery as well as preparation and application thereof

A lithium-ion battery and non-aqueous electrolyte technology, which is applied in the field of non-aqueous electrolyte and its preparation, can solve the problems of low cycle life, large irreversible capacity loss of the battery for the first charge and discharge, etc., to inhibit decomposition, improve capacity storage characteristics, Effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

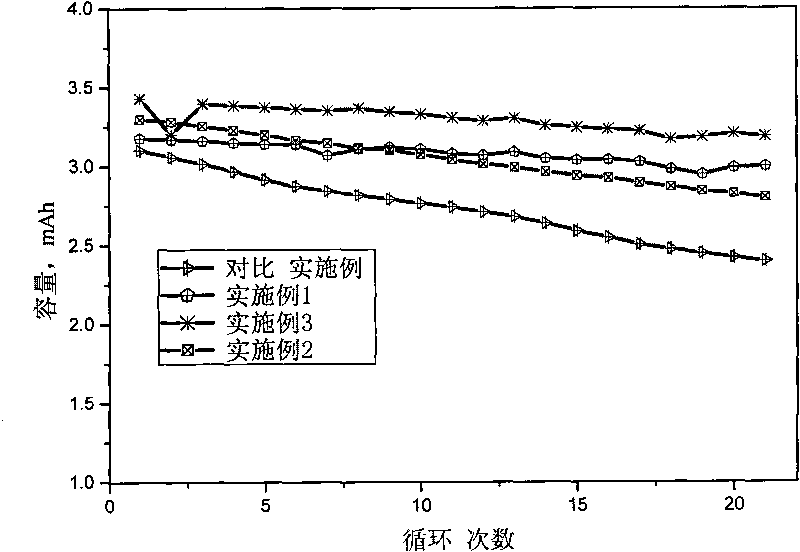

Embodiment 1

[0033] (1) Mix ethylene carbonate (EC), dimethyl carbonate (DMC) and diethyl carbonate (DEC) with a mass ratio of EC:DMC:DEC=1:1:1, and use Molecular sieve, calcium hydride and sodium hydride are used for impurity removal and water removal, and then vacuum filtration in a glove box filled with high-purity argon to obtain a non-aqueous solvent;

[0034] (2) At room temperature, the LiPF 6 Add to the non-aqueous solvent in batches, add the process control temperature below 40 ℃, LiPF 6 The concentration of 1mol / L, and stir evenly to obtain ordinary electrolyte;

[0035] (3) In the common electrolyte, add dimethyl vinylene carbonate in an amount of 2% by mass of the common electrolyte to obtain a non-aqueous electrolyte for lithium ion batteries.

Embodiment 2

[0037] (1) Mix ethylene carbonate (EC), dimethyl carbonate (DMC) and diethyl carbonate (DEC) with a mass ratio of EC:DMC:DEC=1:1:1, and use Molecular sieve, calcium hydride, sodium hydride are purified to remove impurities and water, and then filtered under reduced pressure in a glove box filled with high-purity argon to obtain a non-aqueous solvent;

[0038] (2) At room temperature, the LiPF 6 Dissolved in the above non-aqueous solvent, LiPF 6 The concentration of 1mol / L, and stir evenly to obtain ordinary electrolyte;

[0039] (3) In the common electrolyte, furanone is added in an amount of 2% by mass of the common electrolyte to obtain a non-aqueous electrolyte for lithium ion batteries.

Embodiment 3

[0041] (1) Mix ethylene carbonate (EC), dimethyl carbonate (DMC) and diethyl carbonate (DEC) with a mass ratio of EC:DMC:DEC=1:1:1, and use Molecular sieve, calcium hydride, sodium hydride are purified to remove impurities and water, and then filtered under reduced pressure in a glove box filled with high-purity argon to obtain a non-aqueous solvent;

[0042] (2) At room temperature, the LiPF 6 Add to the non-aqueous solvent in batches, add the process control temperature below 40 ℃, LiPF 6 The concentration of 1mol / L, and stir evenly to obtain ordinary electrolyte;

[0043] (3) In the common electrolyte, α-angelica lactone is added in an amount of 2% by mass of the common electrolyte to obtain a non-aqueous electrolyte for lithium ion batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com