Ternary cathode material of lithium ion battery and preparation method of ternary cathode material

A technology for lithium ion batteries and positive electrode materials, applied in battery electrodes, positive electrodes, electrical components, etc., can solve the problems of short cycle performance, different microscopic morphology, poor cycle performance, etc., and achieve energy saving and simple process. , the effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

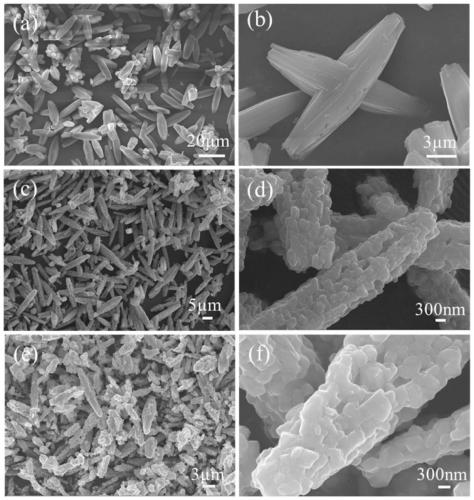

Image

Examples

preparation example Construction

[0031] The preparation and testing instruments adopted in this patent are as follows:

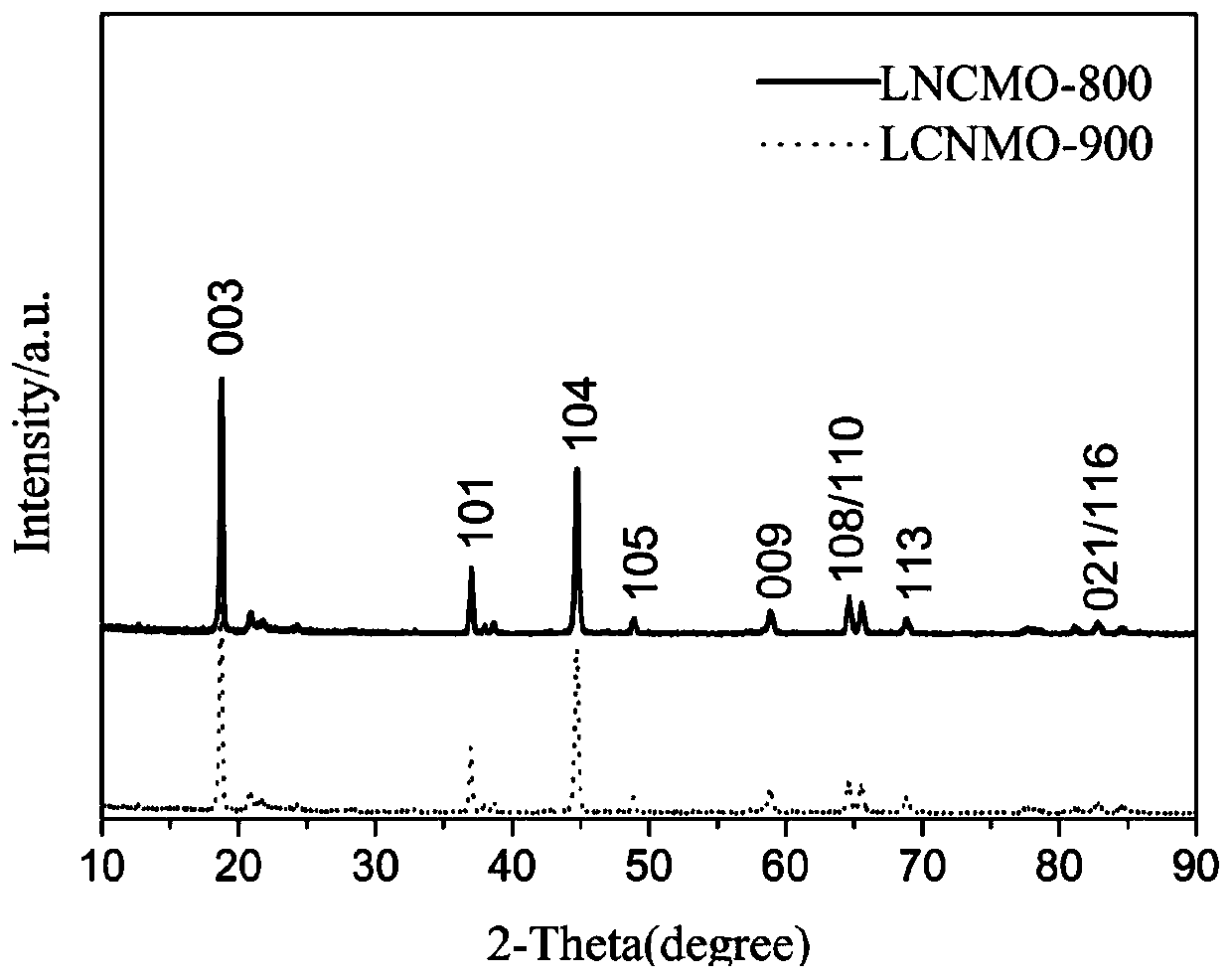

[0032] Microwave digestion instrument (WX-6000), the reaction temperature is 160-200°C, and the reaction time is 30 minutes. X-ray diffraction (D / max-2200-PC), test conditions 10°~80°, 4° per minute. Scanning electron microscope (SIGMA, ZEISSmicroscope). Thermogravimetric / differential thermal analysis (TGA / SDTA851), the test condition is 25℃~1000℃. Specific surface test (ASAP2020). Landian (Wuhan LAND), keep the room temperature at 25°C during the test.

Embodiment 1

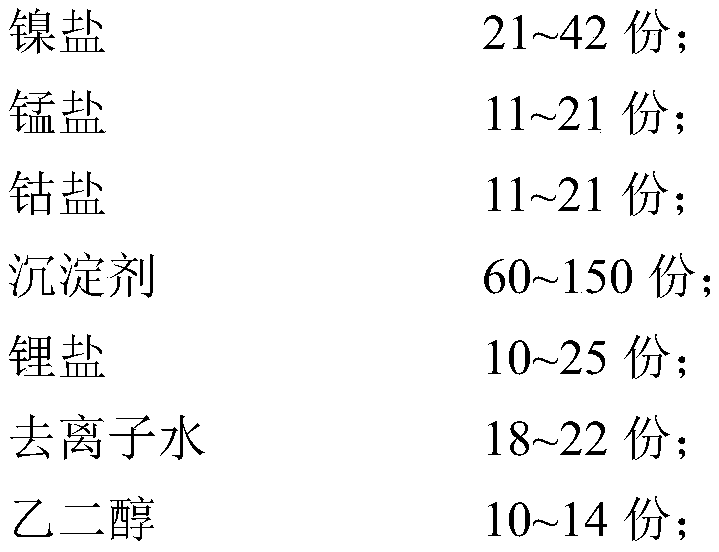

[0034] A lithium-ion battery ternary positive electrode material, the raw materials used in its preparation are calculated in parts by weight, and its composition and content are as follows:

[0035]

[0036] Wherein, the nickel salt is nickel sulfate hexahydrate;

[0037] Described manganese salt is manganese sulfate tetrahydrate;

[0038] Described cobalt salt is cobalt sulfate heptahydrate;

[0039] Described precipitation agent is dimethyl oxalate;

[0040] Described lithium salt is lithium acetate;

[0041] The above-mentioned ternary positive electrode material for a lithium ion battery and a preparation method thereof specifically include the following steps:

[0042](1) Preparation of precursors: Add nickel sulfate hexahydrate, manganese sulfate tetrahydrate and cobalt sulfate heptahydrate into deionized water in proportion, and stir continuously to directly form a transparent salt solution. Mix dimethyl oxalate and ethylene glycol and stir constantly to form a ...

Embodiment 2

[0045] A lithium-ion battery ternary positive electrode material, the raw materials used in its preparation are calculated in parts by weight, and its composition and content are as follows:

[0046]

[0047] Wherein, the nickel salt is nickel acetate tetrahydrate;

[0048] Described manganese salt is manganese acetate tetrahydrate;

[0049] Described cobalt salt is cobalt acetate tetrahydrate;

[0050] Described precipitation agent is dimethyl carbonate;

[0051] Described lithium salt is lithium hydroxide;

[0052] The above-mentioned ternary positive electrode material for a lithium ion battery and a preparation method thereof specifically include the following steps:

[0053] (1) Preparation of precursors: Add nickel acetate tetrahydrate, manganese acetate tetrahydrate and cobalt acetate tetrahydrate into deionized water according to the routine, and stir continuously to directly form a transparent salt solution. Mix dimethyl carbonate and ethylene glycol with const...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com