Liquid metal insulation and heat-conduction material and preparation method thereof

A liquid metal, insulating and thermally conductive technology, applied in heat exchange materials, chemical instruments and methods, coatings, etc., can solve the problems of unstable product properties, restricting the development and application of liquid metal type thermal interface materials, etc., to solve leakage current. Risks, satisfying high performance, and the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a liquid metal insulating and heat-conducting material, including liquid metal Ga 71 In 15 sn 13 Zn 1 , aluminum nitride and dimethyl silicone oil with a viscosity of 1000CS, the liquid metal Ga 71 In 15 sn 13 Zn 1 and aluminum nitride are uniformly dispersed in dimethyl silicone oil after being modified by a surface modification solution prepared by dissolving Span85 in absolute ethanol.

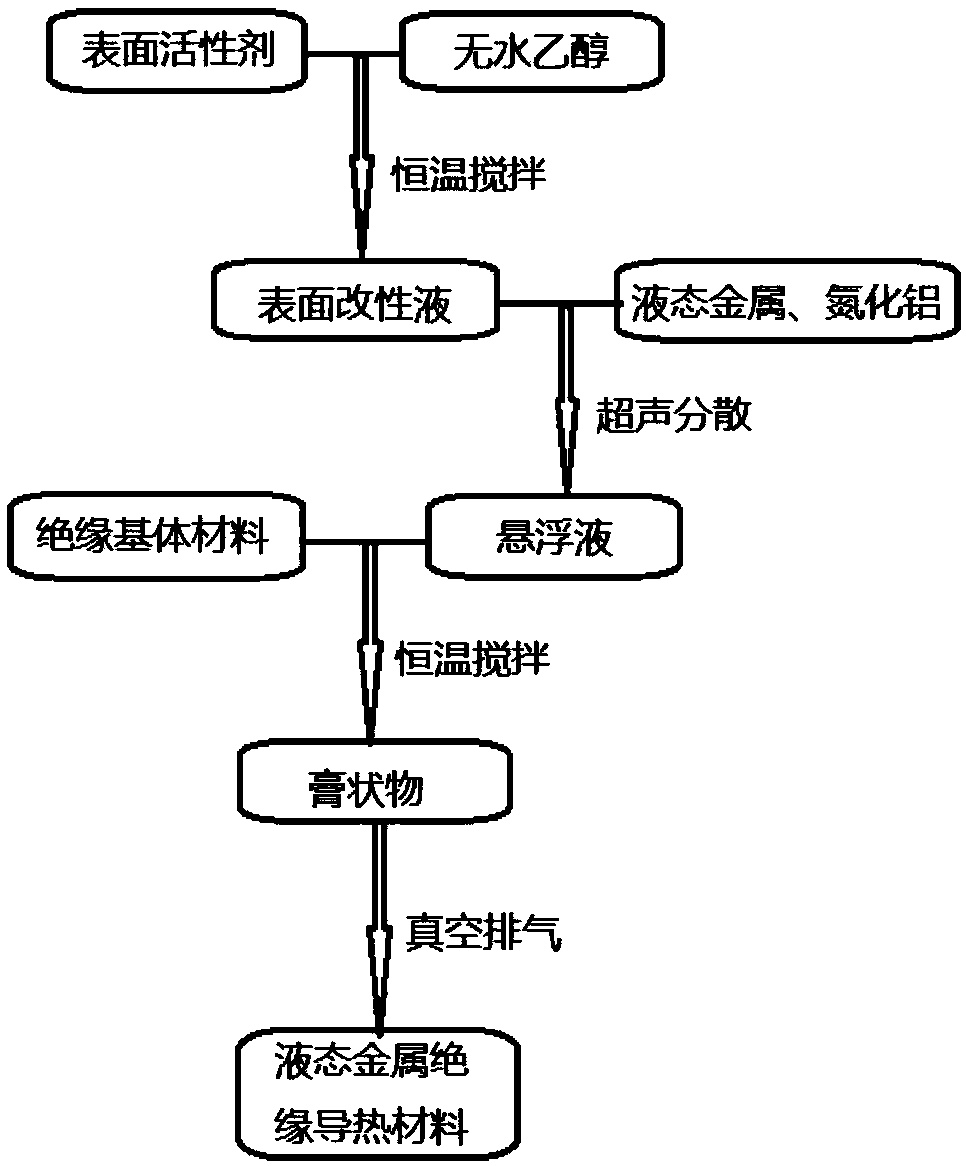

[0041] This embodiment also provides a preparation method for the above-mentioned liquid metal insulating and heat-conducting material, including the following steps:

[0042] (1) Weigh 71% gallium, 15% indium, 13% tin and 1% zinc by mass percentage, first put metal gallium into a beaker, heat it at 100°C, and add tin to the beaker after the gallium is completely melted and indium, after the tin and indium are melted, add zinc into the beaker, after the zinc is melted, put a magnetic stirrer, set the speed at 200r / min, stir in the air for 10min, separa...

Embodiment 2

[0053] The rest are the same as in Example 1, except for the content of liquid metal. In this embodiment, 35g of liquid metal is used to participate in the preparation.

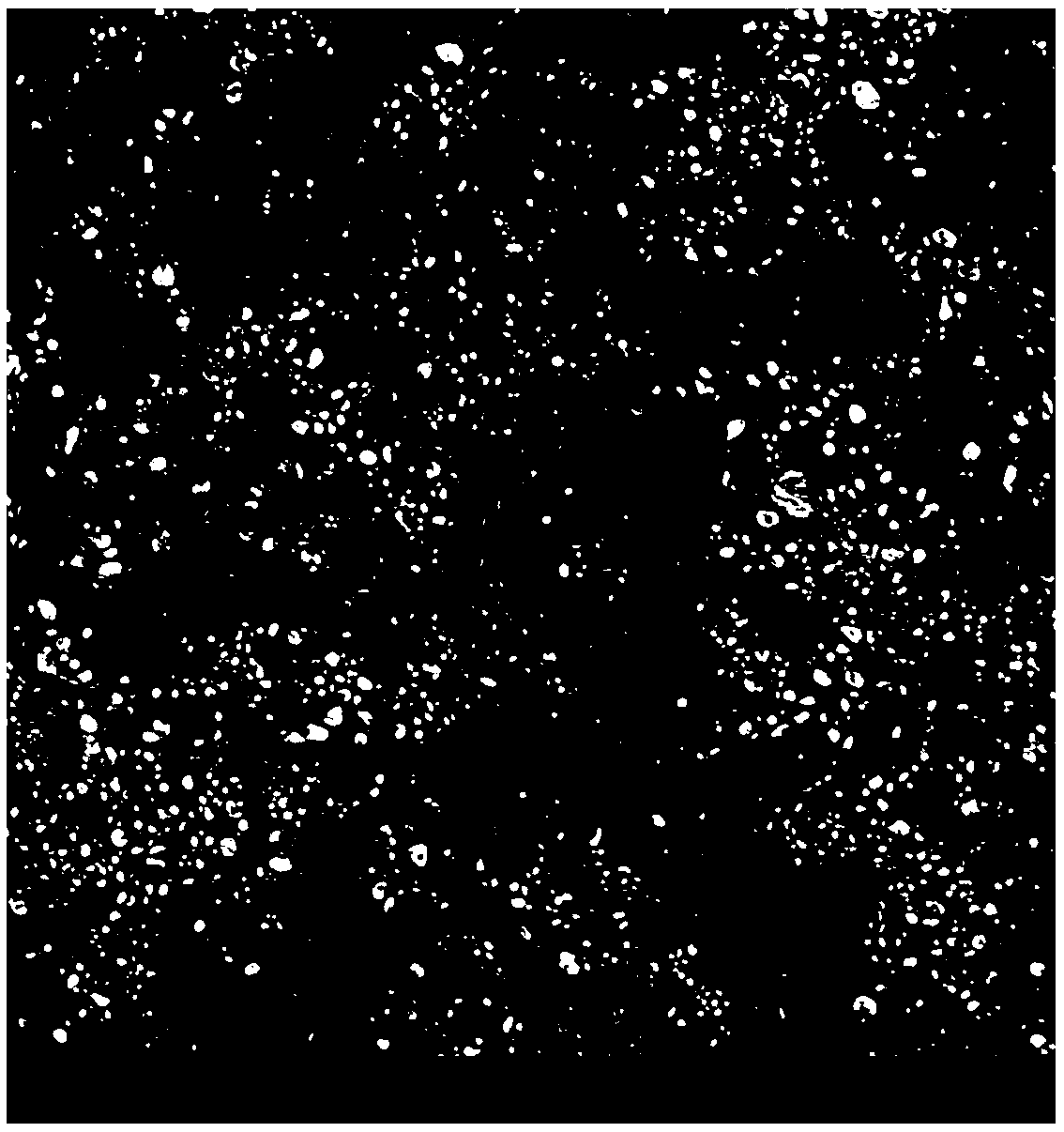

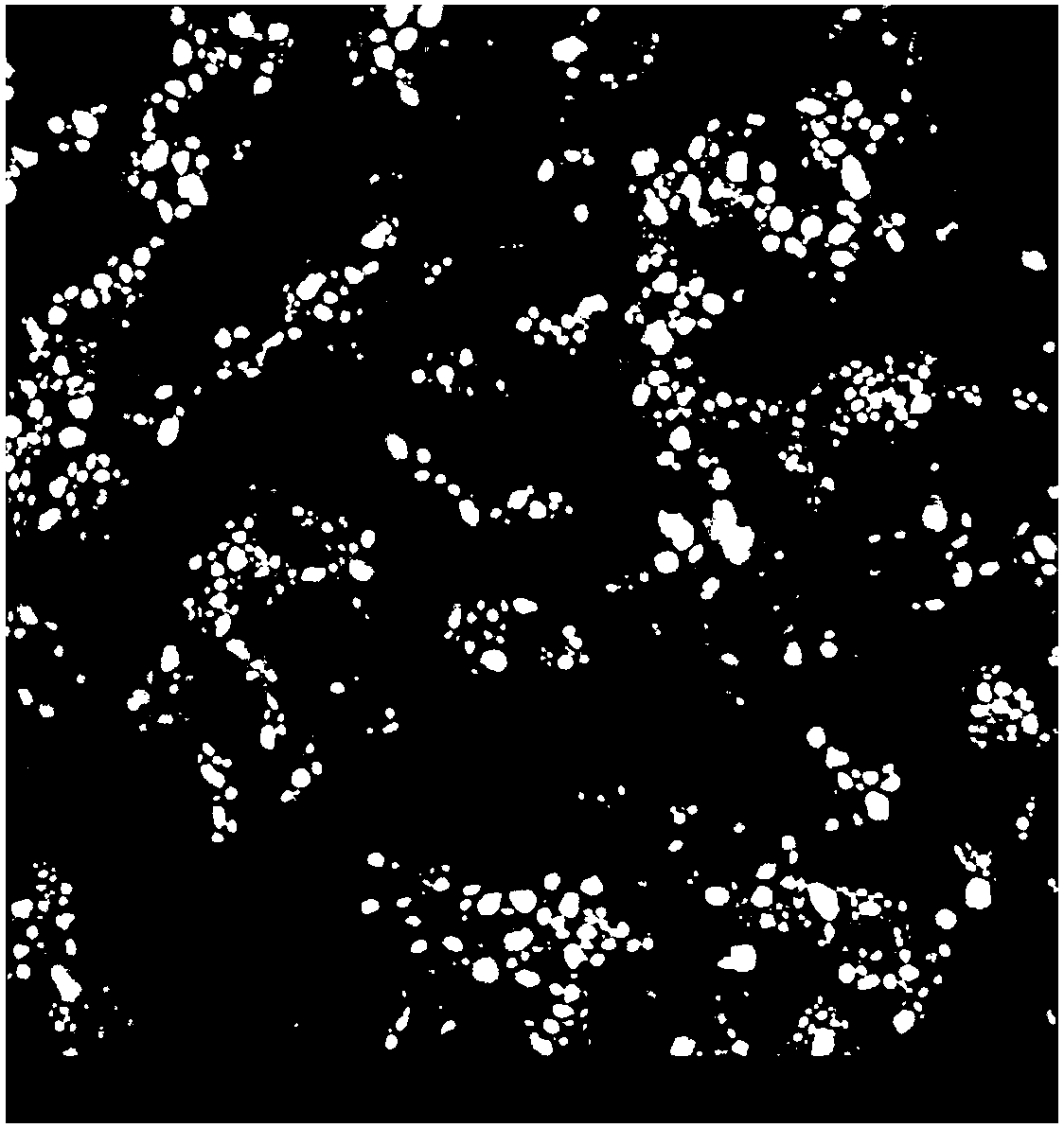

[0054] Using SEM to observe the final product, its microscopic appearance is as follows Figure 4 and Figure 5 As shown, aluminum nitride and liquid metal present a "ball-ball" state.

[0055] Utilize the HPS68004 megger to measure the volume resistivity of the final product, the result is 4.9×10 10 Ω·m.

[0056] The thermal conductivity of the final product was measured with a HotDisk thermal constant analyzer, and the result was 4.652 W / (m·K).

[0057] The liquid metal insulating and heat-conducting material was stored at room temperature for 15 days, and there was no leakage of silicone oil and no precipitation of liquid metal.

[0058] The liquid metal insulating and heat-conducting material was applied to the surface of the electronic components of the aluminum-based material and the copper-based ma...

Embodiment 3

[0060] The rest are the same as in Example 2, except for the content of simethicone. In this example, 6g of simethicone is used to participate in the preparation.

[0061] Using SEM to observe the final product, its microscopic appearance is as follows Image 6 and Figure 7 As shown, aluminum nitride and liquid metal present a "ball-ball" state.

[0062] Utilize the HPS68004 megger to measure the volume resistivity of the final product, the result is 5.3×10 10 Ω·m.

[0063] The thermal conductivity of the final product was measured with a HotDisk thermal constant analyzer, and the result was 3.403 W / (m·K).

[0064] The liquid metal insulating and heat-conducting material was stored at room temperature for 15 days, and there was no leakage of silicone oil and no precipitation of liquid metal.

[0065] The liquid metal insulating and heat-conducting material is respectively applied to the surface of the electronic components of the aluminum-based material and the copper-bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com