Surface-treated stainless-steel sheet with excellent corrosion resistance in salt damage environment for automotive fuel tank

A technology of surface treatment and corrosion resistance, applied in the field of surface treatment of stainless steel plates and fuel tanks, it can solve the problems of stress corrosion cracking, not necessarily anti-corrosion effect, and alloy layer cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] The present invention will be described in more detail below based on examples.

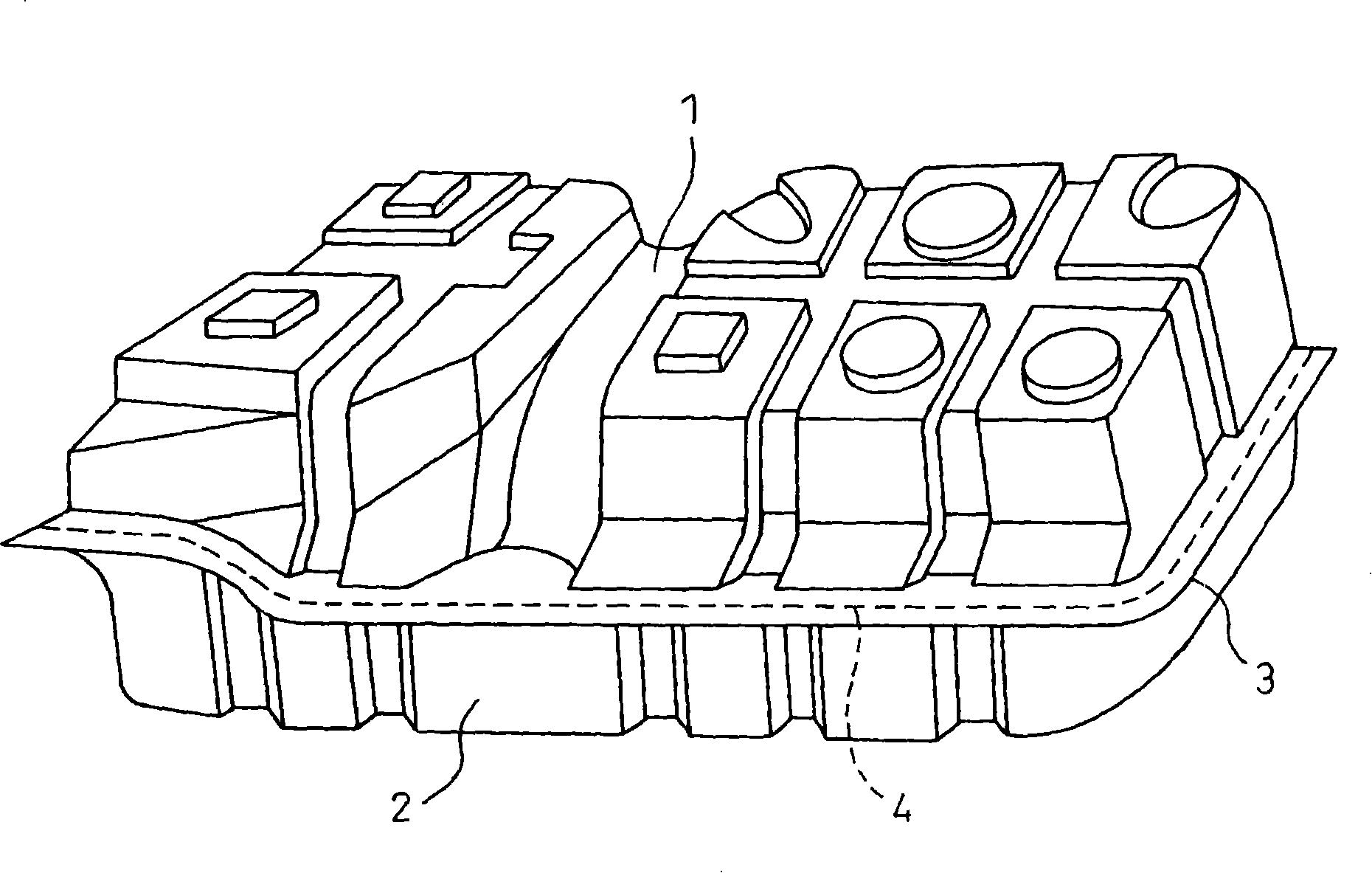

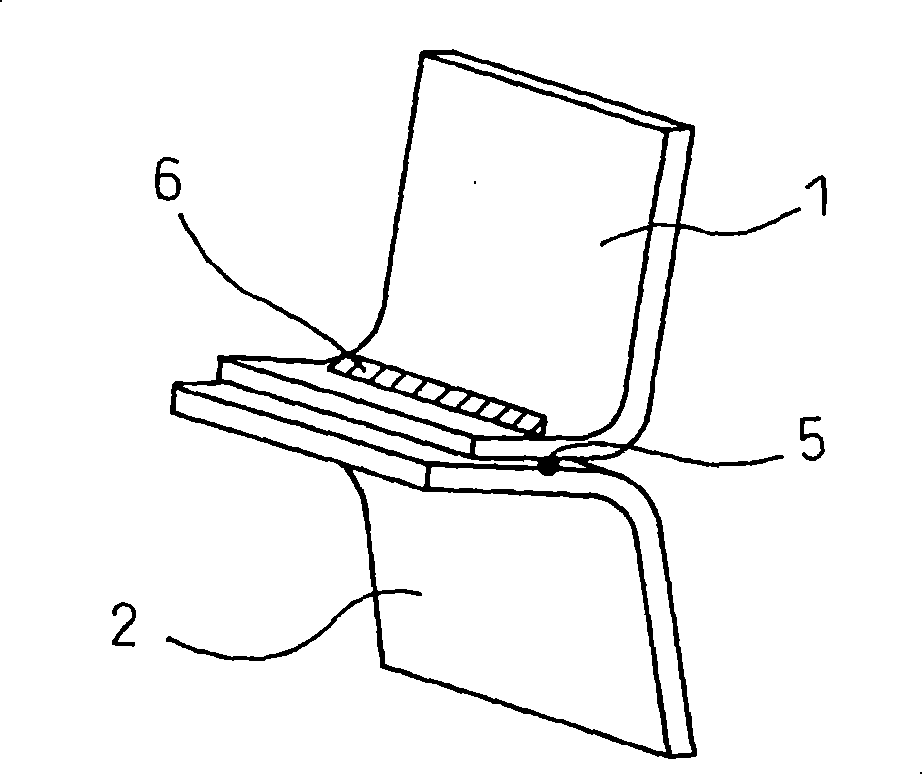

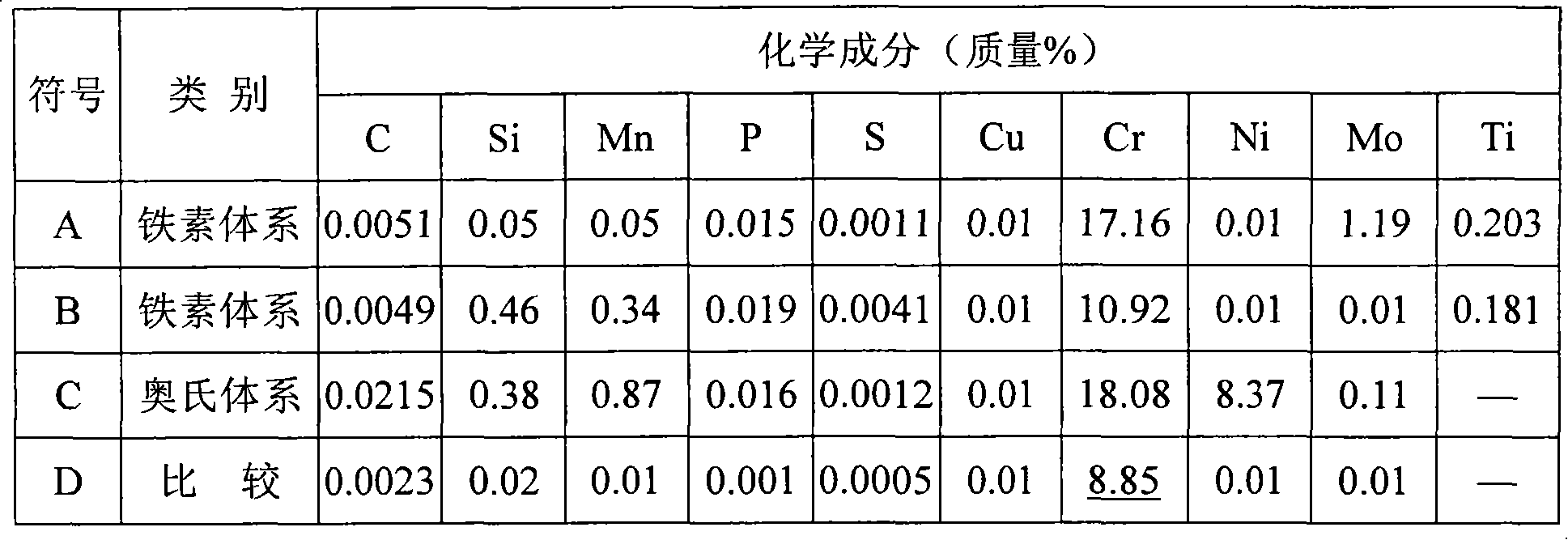

[0050] Steel slabs of ferritic stainless steel A, austenitic stainless steel B and comparative steel C having the compositions shown in Table 1 were hot rolled - hot rolled sheet annealing - pickling - first cold rolling - intermediate annealing - second Sub-cold rolling-final annealing process to produce a steel plate with a plate thickness of 0.8mm. The annealing of hot-rolled sheet varies in the range of 900-1000°C, the cumulative reduction of cold-rolling varies in the range of 70-85%, and the intermediate annealing and final annealing change in the range of 750-1000°C, thereby changing the material properties. A test piece was cut out from this steel plate and subjected to a tensile test, and the material properties shown in Table 2 were obtained.

[0051] Table 1

[0052]

[0053] Note) The underline indicates that it is outside the scope of the present invention

[0054] For thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com