PBT composite material used for NMT forming and preparation method thereof

A technology of composite materials and nanomaterials, which is applied in the field of PBT composite materials and its preparation, can solve the problems of affecting the service life of modified PBT materials, affecting the appearance of products, and large warpage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The above-mentioned preparation method for the PBT composite material of NMT molding, comprises the steps:

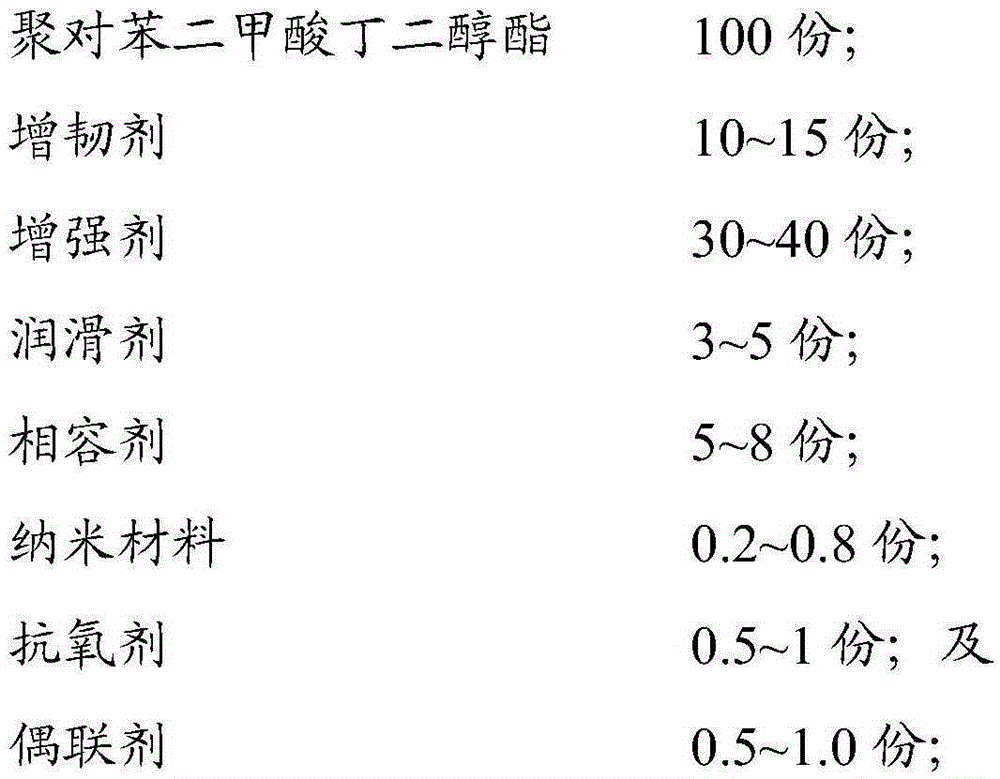

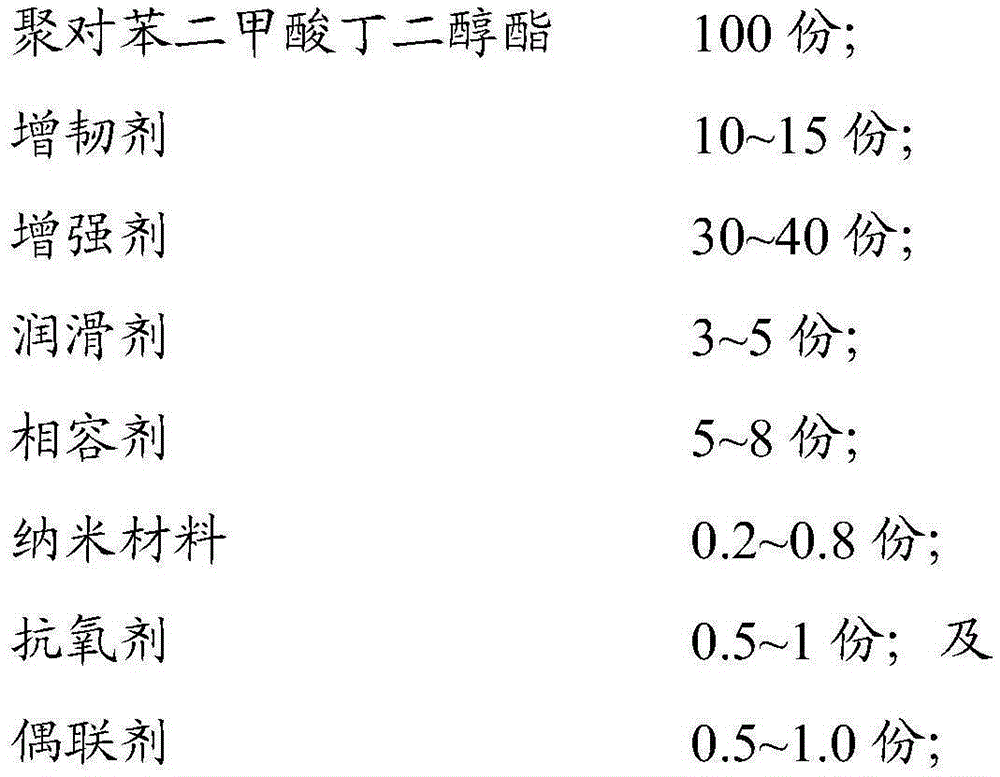

[0041] Step S110, weighing the following raw materials according to the mass fraction: 100 parts of polybutylene terephthalate, 10-15 parts of toughening agent, 30-40 parts of reinforcing agent, 3-5 parts of lubricant, compatibilizer 5-8 parts, 0.2-0.8 parts of nanomaterials, 0.5-1 part of antioxidant, and 0.5-1.0 parts of coupling agent, wherein the nanomaterials are selected from at least one of nano-alumina, nano-magnesia and nano-iron oxide The reinforcing agent is glass fiber.

[0042] Polybutylene terephthalate (PBT) is the main raw material. Preferably, the intrinsic viscosity of PBT resin is 1.15-1.18dL / g, and the density is 1.31-1.33g / cm 3 , Melting point 223~227℃, mass melt flow rate 27~29g / 10min, tensile strength 55.2MPa, flexural strength 81.7MPa.

[0043]Preferably, the toughening agent is an ethylene-octene block copolymer, and the mass content o...

Embodiment 1

[0071] The preparation steps of the PBT composite material used for NMT molding of the present embodiment are as follows:

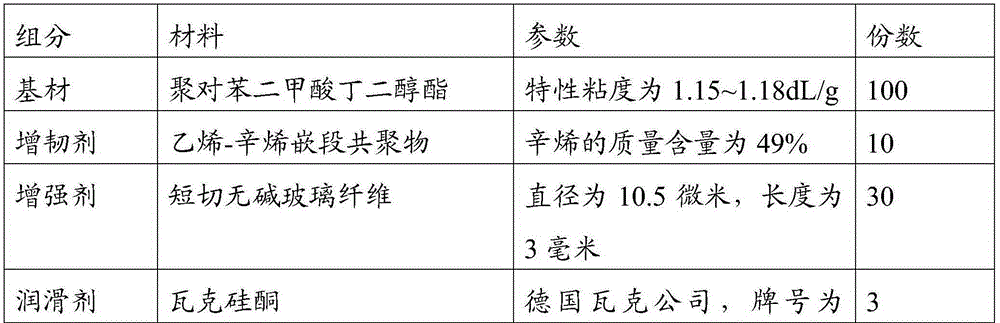

[0072] (1), in parts by mass, take the components in Table 1:

[0073] Table 1

[0074]

[0075]

[0076] (2) Put the nanomaterial in a high-speed mixer, put 1 part of silane coupling agent in beaker A, weigh the absolute ethanol according to the ratio of silane coupling agent: absolute ethanol at 1:2.3 and place it in beaker A, At the same time, stir at room temperature for X minutes to make it evenly mixed; start the high-speed mixer, set the temperature to 70°C, and set it in low-speed mode, add the prepared silane coupling agent ethanol solution at a uniform speed at the upper liquid inlet, after the coupling agent is added Start the high-speed mode and stir at a high speed for 8 minutes to obtain the first material, wherein the rotation speed of the high-speed stirring is 950 rpm.

[0077] (3) Put the glass fiber in a high-speed mixer, put 1 ...

Embodiment 2

[0082] The preparation steps of the PBT composite material used for NMT molding of the present embodiment are as follows:

[0083] (1), in parts by mass, take the components in Table 2:

[0084] Table 2

[0085]

[0086] (2) Put the nanomaterial in a high-speed mixer, put 1 part of silane coupling agent in beaker A, weigh the absolute ethanol according to the ratio of silane coupling agent: absolute ethanol at 1:7 and place it in beaker A, At the same time, stir at room temperature for 2 minutes to make it evenly mixed; start the high-speed mixer, set the temperature to 65°C, and set it in low-speed mode, add the prepared silane coupling agent ethanol solution at a uniform speed at the upper liquid inlet, after the coupling agent is added Start the high-speed mode and stir at a high speed for 1 minute to obtain the first material, wherein the rotation speed of the high-speed stirring is 950 rpm.

[0087] (3) Put the glass fiber in a high-speed mixer, put 1 part of silane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com