Polypropylene material with low linear expansion coefficient and preparation method of polypropylene material

A low linear expansion, polypropylene material technology, applied in the field of materials, can solve the problems of reducing the shrinkage rate of the material, the appearance of floating fibers, the decrease of the rigidity of the material, etc., and achieve the effect of reducing the coefficient of linear expansion, low equipment requirements, and reducing the crystallinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

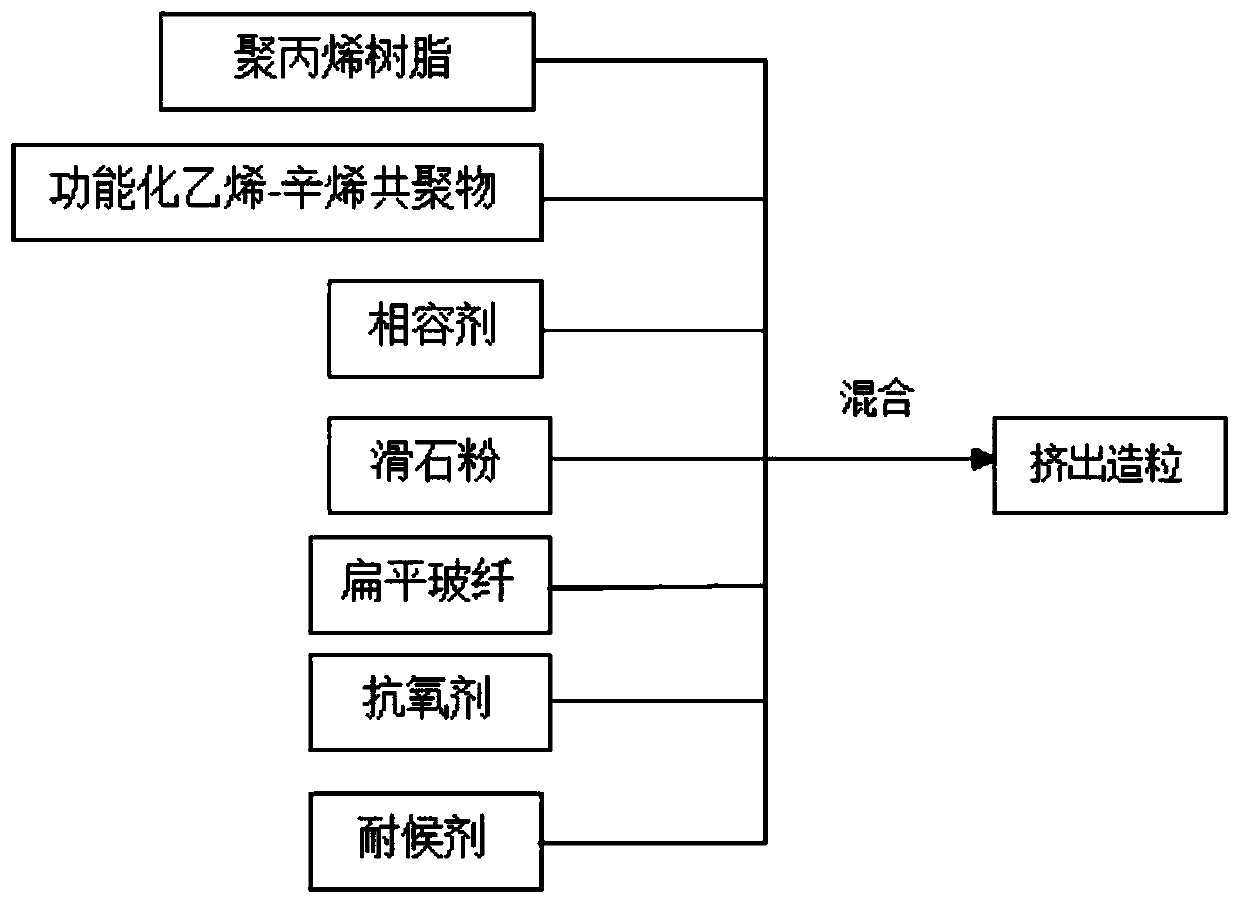

Method used

Image

Examples

preparation example Construction

[0055] The functionalized ethylene-octene copolymer was prepared as follows:

[0056] In parts by weight of raw materials, get 97 parts of ethylene-octene copolymer (POE), 0.1 part of dicumyl peroxide, 1 part of vinyl triisopropoxysilane and 0.5 part of auxiliary crosslinking agent triene Add propyl isocyanurate (TAIC) into a mixer and mix evenly, then put the resulting mixture into an extruder for granulation to obtain the functionalized ethylene-octene copolymer, and the extrusion temperature is 160°C to 180°C ℃.

[0057] The toughening agent in the comparative example refers to ethylene-octene copolymer.

Embodiment 1

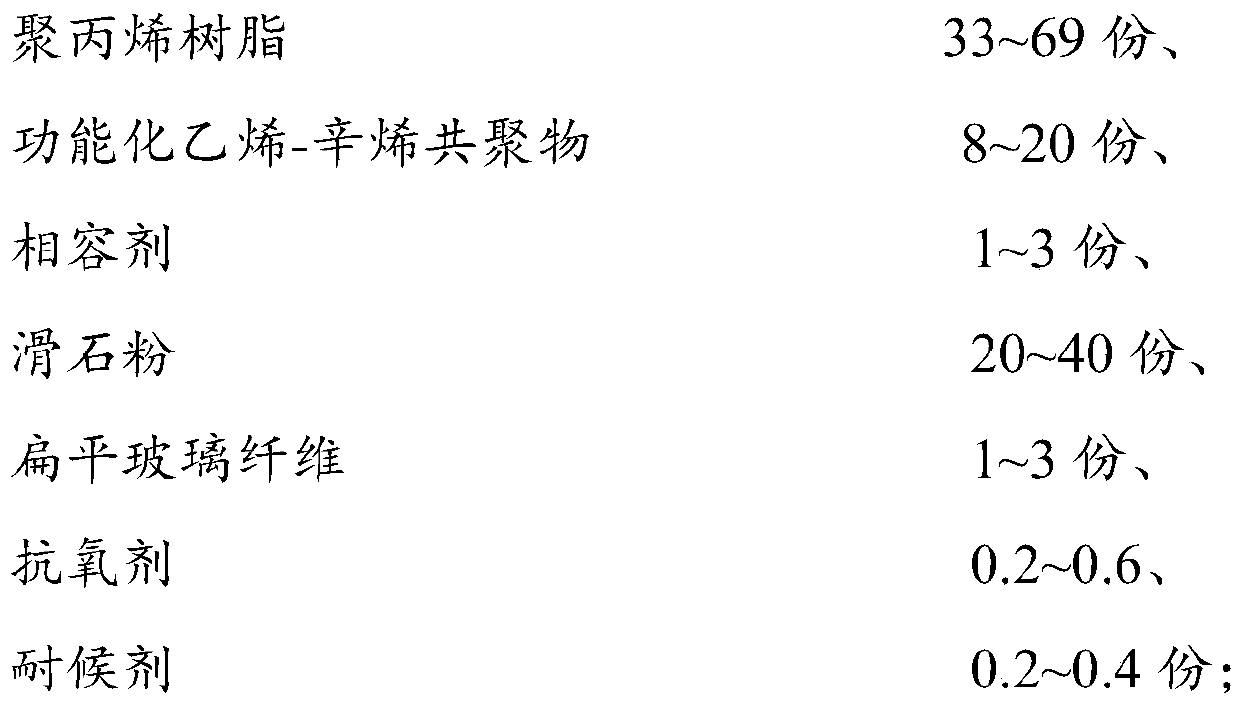

[0059] This embodiment provides a polypropylene material with a low coefficient of linear expansion, which is prepared from the following components in parts by weight of raw materials:

[0060]

[0061] The preparation method of the polypropylene material with low linear expansion coefficient is as follows:

[0062] Polypropylene resin, functionalized ethylene-octene copolymer, compatibilizer, talcum powder, flat glass fiber, antioxidant and weathering agent are added into a high-speed mixer and stirred evenly (the mixer speed is 1000 rpm), and then the resulting The mixed material is fed into the parallel twin-screw extruder from the main feeding port for melt extrusion and granulation. The process parameters include: the temperature of the first zone is 160°C, the temperature of the second zone is 190°C, the temperature of the third zone is 190°C, and the temperature of the fourth zone The temperature of the fifth zone is 190°C, the temperature of the sixth zone is 190°C...

Embodiment 2

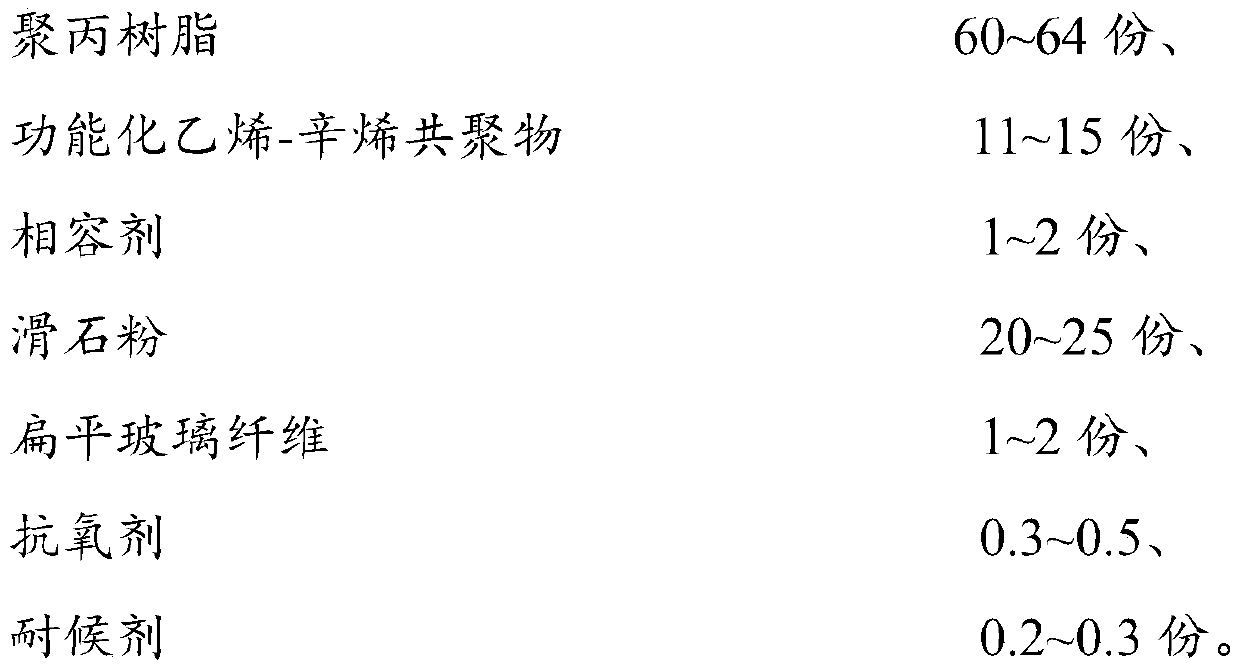

[0065] This embodiment provides a polypropylene material with a low coefficient of linear expansion, which is prepared from the following components in parts by weight of raw materials:

[0066]

[0067] The preparation method of the polypropylene material with low linear expansion coefficient is as follows:

[0068] Polypropylene resin, functionalized ethylene-octene copolymer, compatibilizer, talcum powder, flat glass fiber, antioxidant and weathering agent are added into a high-speed mixer and stirred evenly (the mixer speed is 1000 rpm), and then the resulting The mixed material is fed into the parallel twin-screw extruder from the main feeding port for melt extrusion and granulation. The process parameters include: the temperature of the first zone is 140°C, the temperature of the second zone is 220°C, the temperature of the third zone is 220°C, and the temperature of the fourth zone The temperature of the fifth zone is 220°C, the temperature of the sixth zone is 220°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com