High-melt-strength high-bonding-property thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer, high melt strength technology, applied in the field of thermoplastic elastomers, can solve the problems of low melt strength, easy shrinkage, poor mechanical strength and encapsulation adhesion, etc., to achieve high melt strength, not easy to shrink, Effect of Improving Extrusion Processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

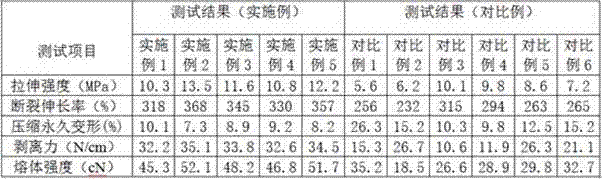

Examples

Embodiment 1

[0023] A thermoplastic elastomer with high melt strength and high adhesion, the basic formula and weight ratio are: 25 parts of styrene-isoprene-styrene block copolymer, 20 parts of random copolymerized polypropylene, polyether type 6 parts of thermoplastic polyurethane, 5 parts of hydroxyl-terminated dendritic polyamide ester, 3 parts of terpene-styrene resin, 2 parts of bicyclodiene petroleum resin, 14 parts of naphthenic oil, 3 parts of maleic anhydride grafted SEBS, antioxidant 2 doses.

[0024] The above-mentioned high-melt-strength high-bonding thermoplastic elastomer has the following steps for its preparation:

[0025] (1) Weigh the raw materials in the formula according to the weight ratio, add the high molecular weight styrene copolymer, thermoplastic polyurethane, and high boiling point filler oil into the high mixer, stir for 30 minutes, and mix well;

[0026] (2) Put the remaining other raw materials into the high mixer together with the raw materials mixed in st...

Embodiment 2

[0029] A thermoplastic elastomer with high melt strength and high adhesion, the basic formula and weight ratio are: 35 parts of styrene-isoprene-styrene block copolymer, 30 parts of random copolymerized polypropylene, polyether type 14 parts of thermoplastic polyurethane, 12 parts of hydroxyl-terminated dendritic polyester, 8 parts of terpene-phenolic resin, 9 parts of hydrogenated petroleum resin, 20 parts of paraffin oil, 14 parts of maleic anhydride grafted SEBS, and 6 parts of antioxidant.

[0030] The above-mentioned high-melt-strength high-bonding thermoplastic elastomer has the following steps for its preparation:

[0031] (1) Weigh the raw materials in the formula according to the weight ratio, add the high molecular weight styrene copolymer, thermoplastic polyurethane, and high boiling point filler oil into the high mixer, stir for 60 minutes, and mix well;

[0032] (2) Put the remaining other raw materials into the high mixer together with the raw materials mixed in ...

Embodiment 3

[0035] A thermoplastic elastomer with high melt strength and high adhesion, the basic formula and weight ratio are: 30 parts of styrene-isoprene-styrene block copolymer, 25 parts of random copolymerized polypropylene, polyether type 10 parts of thermoplastic polyurethane, 8 parts of hydroxyl-terminated dendritic polyamide ester, 5 parts of terpene-phenolic resin, 6 parts of bicyclodiene petroleum resin, 17 parts of paraffin oil, 8 parts of maleic anhydride grafted SEBS, and 4 parts of antioxidant share.

[0036] The above-mentioned high-melt-strength high-bonding thermoplastic elastomer has the following steps for its preparation:

[0037] (1) Weigh the raw materials in the formula according to the weight ratio, add high molecular weight styrene copolymer, thermoplastic polyurethane, and high boiling point filler oil into the high mixer, stir for 45 minutes, and mix well;

[0038] (2) Put the remaining other raw materials into the high mixer together with the raw materials mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com