High-rigidity, low-odor and low-linearity polypropylene whisker modified material

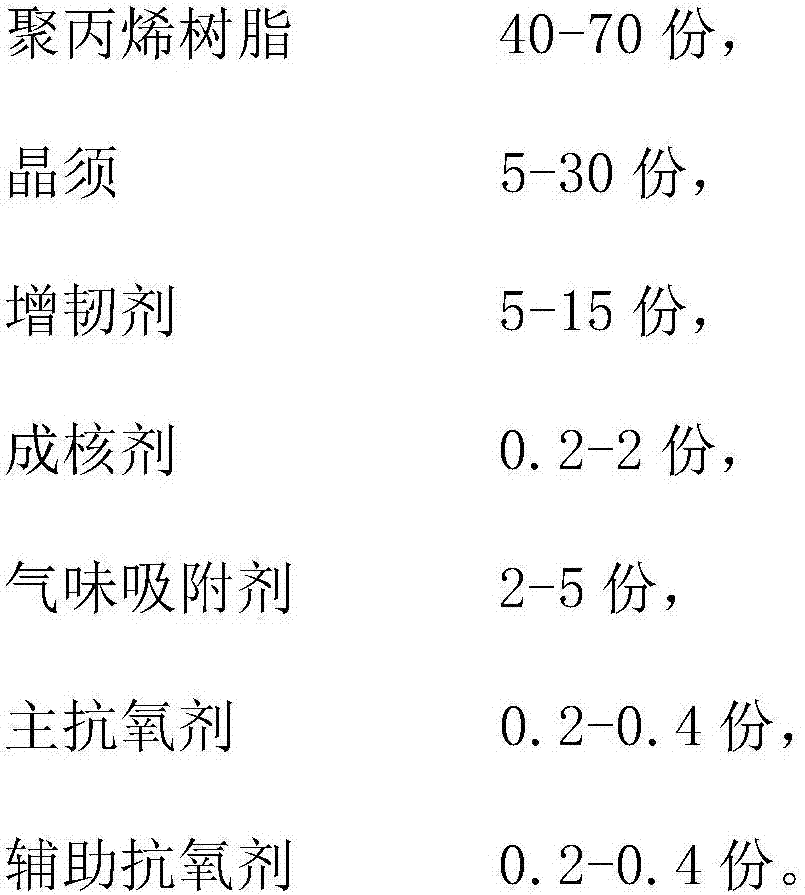

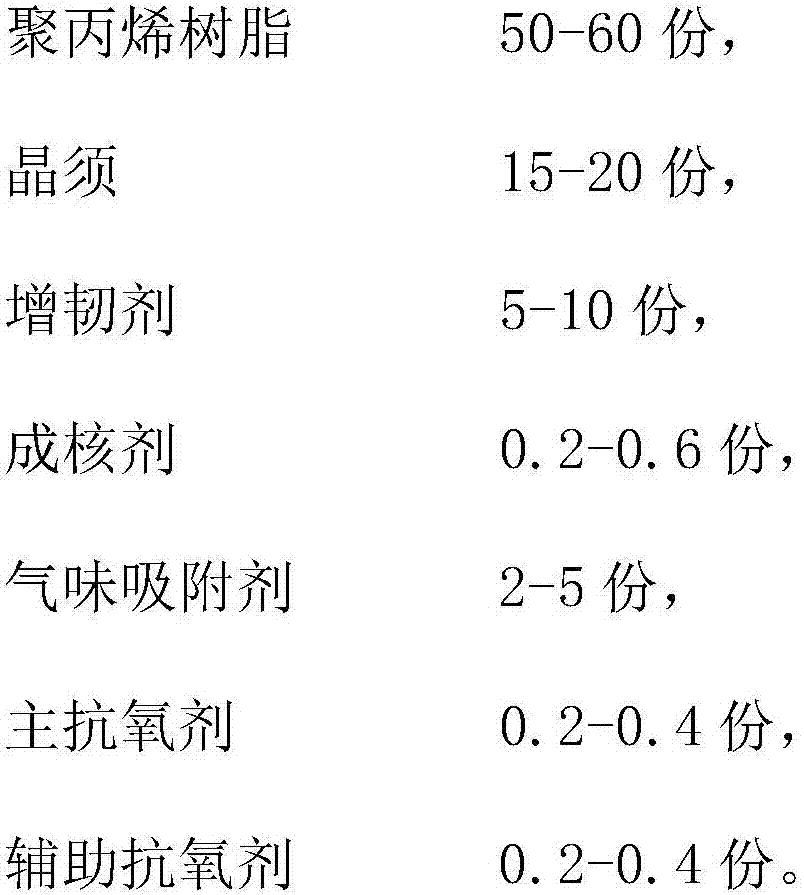

A linear polypropylene, low odor technology applied to low linear polypropylene whisker compounds. , high impact, high rigidity, low odor field, can solve the problems of thermal deformation temperature, small dimensional stability help, material odor cannot be guaranteed, and it is difficult to apply auto parts, etc., to achieve easy implementation, improve dimensional stability, and reduce linear expansion coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A high-impact, high-rigidity, low-odor, low-linear polypropylene whisker modified material, which is made of the following raw materials in parts by weight: impact copolymer polypropylene 1 30.0, impact copolymer polypropylene 2 10.0 , homopolypropylene 20.0, toughening agent 1 (SEBS) 3.0, toughening agent 2 (ethylene-octene copolymer) 7.0, whisker (whisker masterbatch) 20.0, nucleating agent 1 (HPN20E) 0.2, into Nucleating Agent 2 (TMB-5) 0.2, Odor Adsorbent 2.0, Antioxidant 1010 0.3, Antioxidant 168 0.3.

[0039] The preparation method of the described high-impact, high-rigid, low-odor, low-linear polypropylene whisker modified material comprises the following steps:

[0040] (1) Weigh polypropylene, whiskers, toughening agent, nucleating agent, odor adsorbent, primary antioxidant and auxiliary antioxidant, and mix it in a high-speed mixer for 1-3min at high speed, mix well, Get the premix.

[0041] (2) Add the premixed material into the main feeding port of the twi...

Embodiment 2

[0044] A high-impact, high-rigidity, low-odor, low-linear polypropylene whisker modified material, the modified material is made of raw materials including the following parts by weight: impact copolymer polypropylene 1 37.0, impact copolymer polypropylene 2 10.0 , homopolypropylene 20.0, toughening agent 1 (SEBS) 3.0, toughening agent 2 (ethylene-octene copolymer) 7.0, whiskers (whisker masterbatch) 15.0, nucleating agent 1 (HPN20E) 0.2, into Nucleating Agent 2 (TMB-5) 0.4, Odor Adsorbent 2.0, Antioxidant 1010 0.3, Antioxidant 168 0.3.

[0045] The preparation method of the high-impact, high-rigid, low-odor, low-linear polypropylene whisker-modified material is the same as that in Example 1.

Embodiment 3

[0047]A high-impact, high-rigidity, low-odor, low-linear polypropylene whisker modified material, the modified material is made of raw materials including the following parts by weight: impact copolymer polypropylene 1 42.0, impact copolymer polypropylene 2 10.0 , homopolypropylene 20.0, toughening agent 1 (SEBS) 2.0, toughening agent 2 (ethylene-octene copolymer) 3.0, whisker (whisker masterbatch) 10.0, nucleating agent 2 (TMB-5) 0.4 , odor adsorbent 2.0, antioxidant 1010 0.3, antioxidant 168 0.3, placed in a high-speed mixer and fully stirred.

[0048] The preparation method of the high-impact, high-rigid, low-odor, low-linear polypropylene whisker-modified material is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com