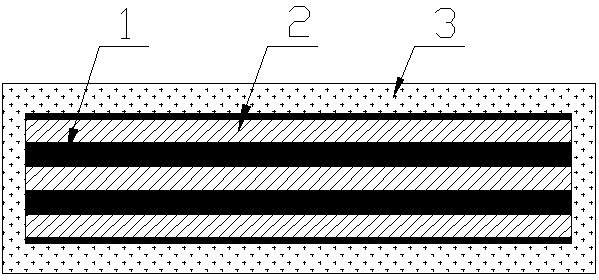

Fabric laminated flame-retardant conveyor belt for coal mines

A conveyor belt and fabric technology, used in the fields of antistatic conveyor belts, flame retardant, and laminated flame retardant conveyor belts, can solve the problems of easy deviation and large elongation of the whole core belt, so as to solve the problems of easy deviation and improve Flow properties, effect of slowing down the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Covering rubber 3 formula: 80 parts of neoprene, 10 parts of butadiene rubber, 10 parts of chlorinated polyethylene, 5 parts of zinc oxide, 0.5 parts of sulfur, 6 parts of magnesium oxide, 0.5 parts of accelerator DM, 1 part of stearic acid, 1 part of antioxidant RD, 1 part of antioxidant 4010NA, 2 parts of adhesive RF, 3 parts of adhesive HMMM, 2 parts of adhesive PM-18, 8 parts of antimony trioxide, 10 parts of No. 70 chlorinated paraffin, 6 parts of ammonium polyphosphate, 6 parts of pentaerythritol, 10 parts of zinc borate, 8 parts of MB-202, 20 parts of carbon black N220, 5 parts of triaryl phosphate.

[0037] Adhesive 1 formula: 80 parts of natural rubber, 20 parts of neoprene, 3 parts of sulfur, 4 parts of zinc oxide, 3 parts of magnesium oxide, 0.5 parts of accelerator DM, 1.1 parts of accelerator NOBS, 1 part of stearic acid, antioxidant RD 1.5 parts, adhesive RF 3 parts, adhesive HMMM 4.5 parts, adhesive PM-18 3 parts, white carbon black 8 parts, carbon black N22...

Embodiment 2

[0039] Cover rubber 3 formula: neoprene rubber 70 parts, butadiene rubber 20 parts, chlorinated polyethylene 10 parts, zinc oxide 5 parts, sulfur 1 part, magnesium oxide 6 parts, accelerator DM 1 part, stearic acid 1 part, 1 part of antioxidant RD, 1 part of antioxidant 4010NA, 2 parts of adhesive RF, 3 parts of adhesive HMMM, 2 parts of adhesive PM-18, 8 parts of antimony trioxide, 10 parts of No. 70 chlorinated paraffin, 8 parts of ammonium polyphosphate, 8 parts of pentaerythritol, 15 parts of zinc borate, 10 parts of MB-202, 25 parts of carbon black N220, 5 parts of triaryl phosphate.

[0040] Adhesive 1 formula: 70 parts of natural rubber, 30 parts of neoprene, 2.5 parts of sulfur, 5 parts of zinc oxide, 4 parts of magnesium oxide, 0.5 parts of accelerator DM, 1.1 parts of accelerator NOBS, 1 part of stearic acid, antioxidant RD 1.5 parts, adhesive RF 3 parts, adhesive HMMM 4.5 parts, adhesive PM-18 3 parts, white carbon black 6 parts, carbon black N220 35 parts, ammonium po...

Embodiment 3

[0042] Covering rubber 3 formula: neoprene rubber 70 parts, butadiene rubber 10 parts, chlorinated polyethylene 20 parts, zinc oxide 5 parts, sulfur 0.5 parts, magnesium oxide 6 parts, accelerator DM 0.5 parts, stearic acid 1 part, 1 part of antioxidant RD, 1 part of antioxidant 4010NA, 3 parts of adhesive RF, 4.5 parts of adhesive HMMM, 2 parts of adhesive PM-18, 10 parts of antimony trioxide, 20 parts of No. 70 chlorinated paraffin, 10 parts of ammonium polyphosphate, 10 parts of pentaerythritol, 10 parts of zinc borate, 10 parts of MB-202, 25 parts of carbon black N220, 5 parts of triaryl phosphate.

[0043] Adhesive 1 formula: 60 parts of natural rubber, 40 parts of neoprene, 2 parts of sulfur, 5 parts of zinc oxide, 4 parts of magnesium oxide, 0.5 parts of accelerator DM, 1.1 parts of accelerator NOBS, 1 part of stearic acid, anti-aging agent RD 1.5 parts, adhesive RF 3 parts, adhesive HMMM 4.5 parts, adhesive PM-18 3 parts, white carbon black 6 parts, carbon black N220 35 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com