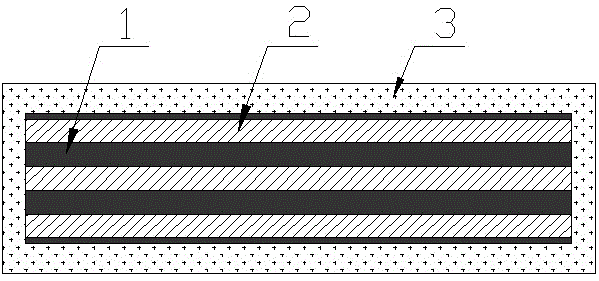

A kind of fabric laminated flame retardant conveyor belt for coal mine

A conveyor belt and fabric technology, applied in the fields of flame retardant, laminated flame retardant conveyor belt, and anti-static conveyor belt, can solve the problems of easy deviation and large elongation of the whole core belt, so as to solve the problem of easy deviation and improve the Flow properties, the effect of improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation technological process of fabric laminated flame-retardant conveyor belt for coal mine is:

[0028] (1) For the mixing of covering rubber 3 and pasting rubber 1, first plasticize and blend on the rubber mixing equipment, adopt a two-stage mixing method, and control the temperature below 135°C during the first stage of internal mixing; during the second stage of internal mixing Add accelerator and some binders, and control the temperature of the mixing room below 100°C; the order of addition is raw rubber, small materials, carbon black, plasticizer, vulcanizing agent, and accelerator.

[0029] (2) Covering rubber 3 is calendered into sheets. After rough refining and refining in the open mill, the covering rubber 3 enters the calender and is calendered into a covering film of required thickness and width. ±5°C, middle roll temperature 70±5°C, bottom roll temperature 45±5°C.

[0030] (3) The two sides of the flame-retardant cloth layer 2 are calendere...

Embodiment 1

[0034] Covering glue 3 formula: 80 parts of neoprene rubber, 10 parts of butadiene rubber, 10 parts of chlorinated polyethylene, 5 parts of zinc oxide, 0.5 parts of sulfur, 6 parts of magnesium oxide, 0.5 parts of accelerator DM, 1 part of stearic acid , 1 part of anti-aging agent RD, 1 part of anti-aging agent 4010NA, 2 parts of adhesive RF, 3 parts of adhesive HMMM, 182 parts of adhesive PM-182 parts, 8 parts of antimony trioxide, 10 parts of No. 70 chlorinated paraffin, 6 parts of ammonium polyphosphate 6 parts, 6 parts of pentaerythritol, 10 parts of zinc borate, 8 parts of MB-2028, 20 parts of carbon black N22020, 5 parts of triaryl phosphate.

[0035] Adhesive 1 formula: 80 parts of natural rubber, 20 parts of neoprene, 3 parts of sulfur, 4 parts of zinc oxide, 3 parts of magnesium oxide, 0.5 parts of accelerator DM, 1.1 parts of accelerator NOBS, 1 part of stearic acid, 1.5 parts of anti-aging agent RD, 3 parts of binder RF, 4.5 parts of binder HMMM, 183 parts of binder...

Embodiment 2

[0037]Covering rubber 3 formula: 70 parts of neoprene rubber, 20 parts of butadiene rubber, 10 parts of chlorinated polyethylene, 5 parts of zinc oxide, 1 part of sulfur, 6 parts of magnesium oxide, 1 part of accelerator DM, 1 part of stearic acid, anti-aging 1 part of anti-aging agent RD, 1 part of anti-aging agent 4010NA, 2 parts of adhesive RF, 3 parts of adhesive HMMM, 182 parts of adhesive PM-18, 8 parts of antimony trioxide, 10 parts of No. 70 chlorinated paraffin, 8 parts of ammonium polyphosphate, 8 parts of pentaerythritol, 15 parts of zinc borate, 10 parts of MB-2020, 25 parts of carbon black N220, 5 parts of triaryl phosphate.

[0038] Adhesive 1 formula: 70 parts of natural rubber, 30 parts of neoprene, 2.5 parts of sulfur, 5 parts of zinc oxide, 4 parts of magnesium oxide, 0.5 parts of accelerator DM, 1.1 parts of accelerator NOBS, 1 part of stearic acid, 1.5 parts of anti-aging agent RD, 3 parts of binder RF, 4.5 parts of binder HMMM, 183 parts of binder PM-183 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com