Control structure suitable for large-diameter steam turbine steam extraction valve and control method

A control structure and steam turbine technology, applied in the direction of valve operation/release device, valve details, valve device, etc., can solve the problems of spring barrel failure, disc spring leaf breakage, etc., to avoid high temperature blow damage and ensure safety , the effect of reducing the length of the movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

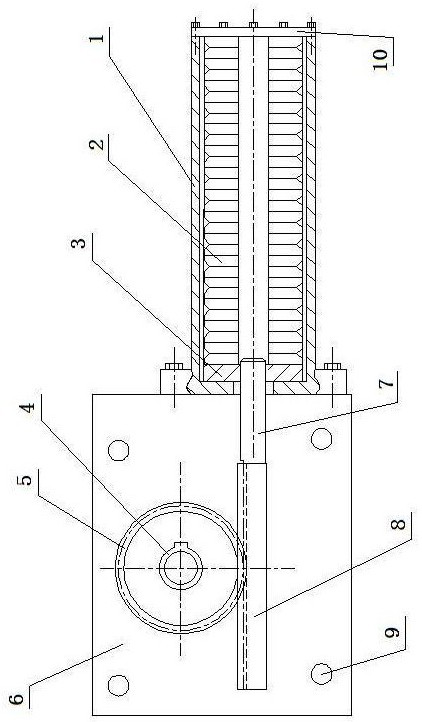

[0021] A control structure suitable for steam extraction valves of large-diameter steam turbines, which consists of: a controller box 6, a gear 5 is installed inside the controller box, and the inner hole of the gear is connected to the valve stem through a flat key 4 connection, the gear is meshed with the rack 8, the left end of the rack is fixed with the guide rod 7, and the guide rod passes through the side wall of the controller box and is threadedly connected with the backing plate 3, so The right side of the backing plate is attached to a set of butterfly springs 2 in sequence, a set of butterfly springs and the backing plate are installed inside the spring barrel 1, and the connecting valve stem is connected to the electric hydraulic cylinder .

Embodiment 2

[0023] According to the control structure applicable to the steam extraction valve of a large-diameter steam turbine described in Embodiment 1, one end of the spring tube is connected to the controller box through a bolt, and the other end of the spring tube is connected to the end cover 10 through a bolt. There is a group of exhaust and drainage holes 9 on the side walls around the controller box.

Embodiment 3

[0025] The control method applicable to the control structure of the large-bore steam turbine extraction valve described in embodiment 1 or 2, the method may further comprise the steps:

[0026] First, install the disc spring in the vertical direction of the connecting valve stem of the butterfly valve, select the number of disc springs that meet the fast closing quantity of the butterfly valve according to the torque of the butterfly valve, and the radius of the thrust rod and the gear is the connecting valve 1.5-2 times the rod radius;

[0027] A toothed groove is machined on the connecting stem of the butterfly valve or a small gear is installed on the finished processed stem in the form of rack and pinion meshing, or a gear perpendicular to the valve stem can be machined or installed The thrust rod of the rod uses the guide rod protruding from the spring barrel to push the rack or thrust rod to make the valve move;

[0028] When the butterfly valve is opened, the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com