Integrated circuit element and forming method of bumping block structure

A technology of integrated circuits and components, applied in the field of bump structure, can solve the problems of high manufacturing cost, interface delamination, solder wetting to the sidewall, etc., to overcome Ni protrusion, increase adhesion, and save process costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

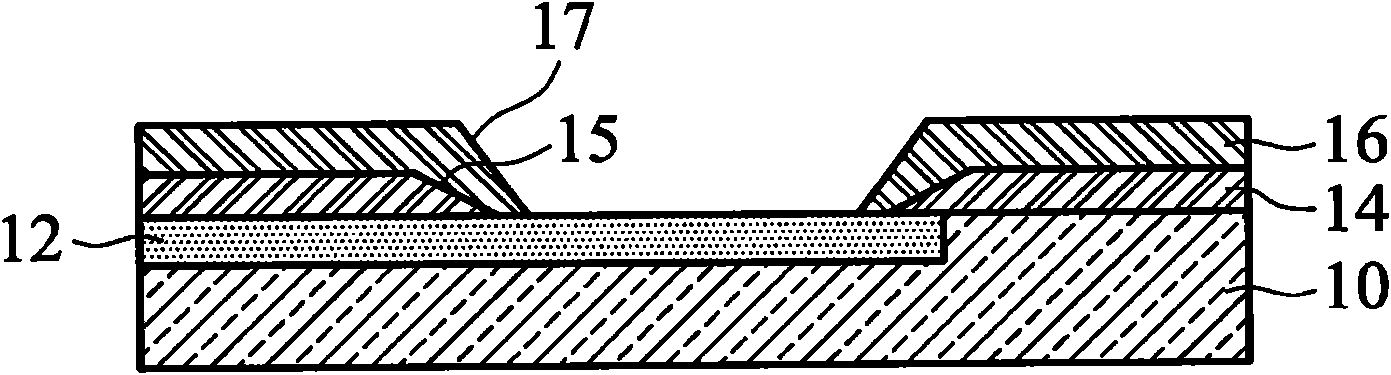

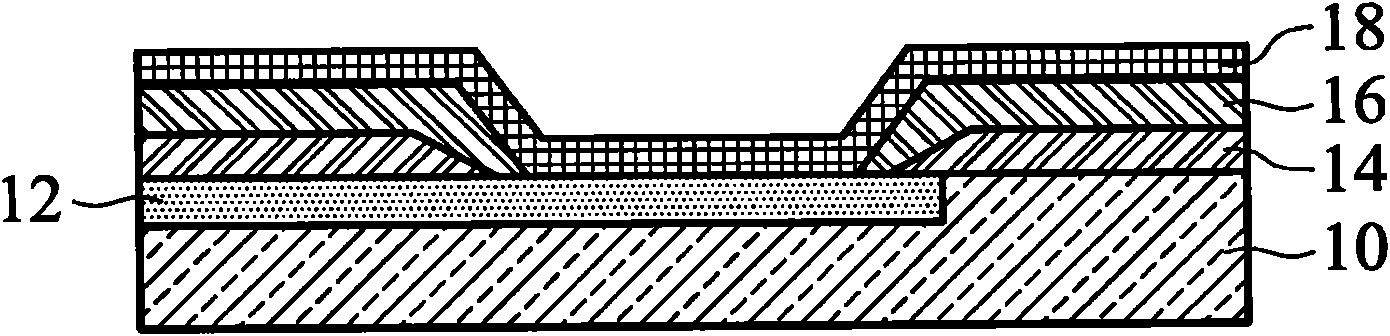

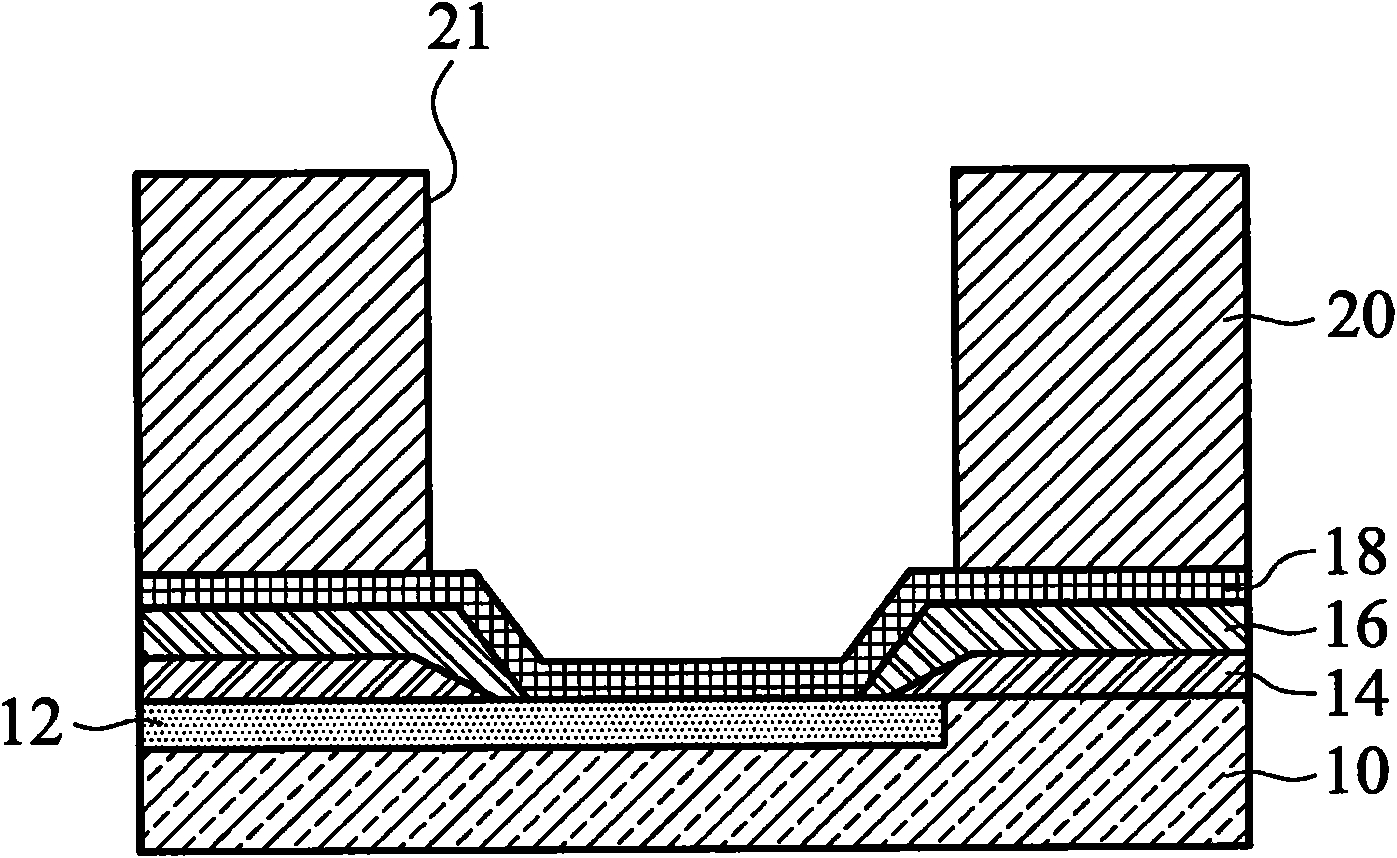

[0014] Embodiments disclosed herein provide a sidewall protection process for copper pillar bump technology, wherein the protection layer on the sidewall of the copper pillar bump is a metal layer formed by an electrolytic process, also referred to herein as electrolytic metal Floor. Copper pillar bumps can be used directly on conductive pads or redistribution layers of semiconductor chips, and can also be used for flip chip assembly or other similar applications.

[0015] In the embodiments of the present invention, the present invention is described in detail with reference to the drawings. As shown in the drawings, the same reference numerals are used as much as possible in the drawings and descriptions to indicate the same or similar parts. In the drawings, the shapes and thicknesses of the embodiments may be exaggerated for the purpose of convenient description and clear display. The description of the specification relates directly to some elements of a device formed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com