The water bath preparation method of cu2znsns4 or cu2cdsns4 nanocrystalline film

A nanocrystalline and thin-film technology, applied in chemical instruments and methods, inorganic chemistry, tin compounds, etc., can solve the problems of device performance degradation, waste of raw materials, and increased investment cost of battery production, achieving low synthesis temperature, simple preparation method, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

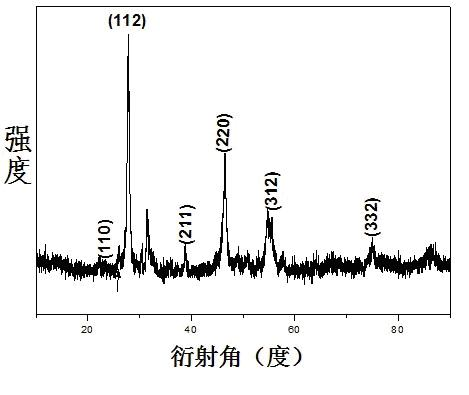

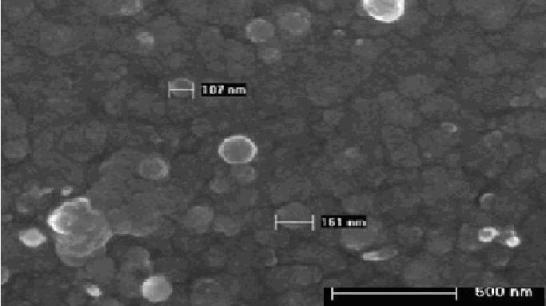

Embodiment 1

[0017] Add 200ml of deionized water, 0.5mmol of copper sulfate, 0.25mmol of zinc chloride, 0.25mmol of stannous chloride, and 1mmol of thioacetamide into the beaker in sequence, and after stirring evenly, add 0.3g of buffering agent edetate disodium and Add 3g of urea into the beaker; then hang the glass that has been ultrasonically cleaned with alcohol, acetone, and deionized water vertically in the beaker; add dilute hydrochloric acid solution to the beaker to adjust the pH value so that the pH of the solution is 2.5; seal the beaker, Place in a water bath and heat to 85 0 C; React for 150 minutes at 450 rev / min stirring speed; after the completion of the reaction, Cu will grow 2 ZnSnS 4 Nanocrystalline thin film glass in argon and hydrogen sulfide (5%) atmosphere 500 0 C annealed for 1h, and finally high-quality Cu 2 ZnSnS 4 nanocrystalline film.

Embodiment 2

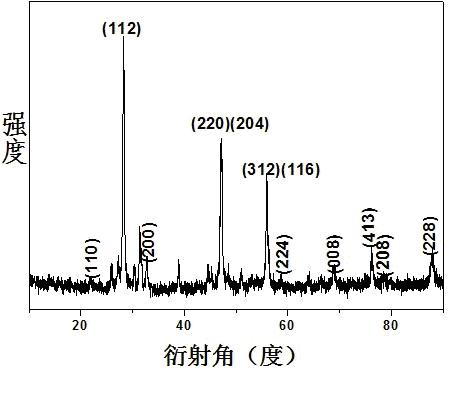

[0019] Add 200ml of deionized water, 0.5mmol of copper acetate, 0.25mmol of cadmium chloride, 0.25mmol of stannous chloride, and 1mmol of thioacetamide into the beaker in turn. After stirring evenly, add 0.3g of buffering agent edetate disodium and Add 3g of urea into the beaker; then hang the glass that has been ultrasonically cleaned with alcohol, acetone, and deionized water vertically in the beaker; add dilute hydrochloric acid solution to the beaker to adjust the pH value so that the pH of the solution is 3.5; seal the beaker, Place in a water bath and heat to 85 0 C; React for 150 minutes at 450 rev / min stirring speed; after the completion of the reaction, Cu will grow 2 CdSnS 4 The glass of nanocrystalline film is 500 in the atmosphere of argon and hydrogen sulfide (5%) 0 C annealed for 1h, and finally high-quality Cu 2 CdSnS 4 nanocrystalline film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com