Use of CuO nano-needle/Cu base-plate material in solar dye battery

A technology of solar cells and nanoneedles, which is applied in the field of nanomaterials and nanometers, can solve the problems of few researches and high cost of cathodes, and achieve the effects of low cost, high controllability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

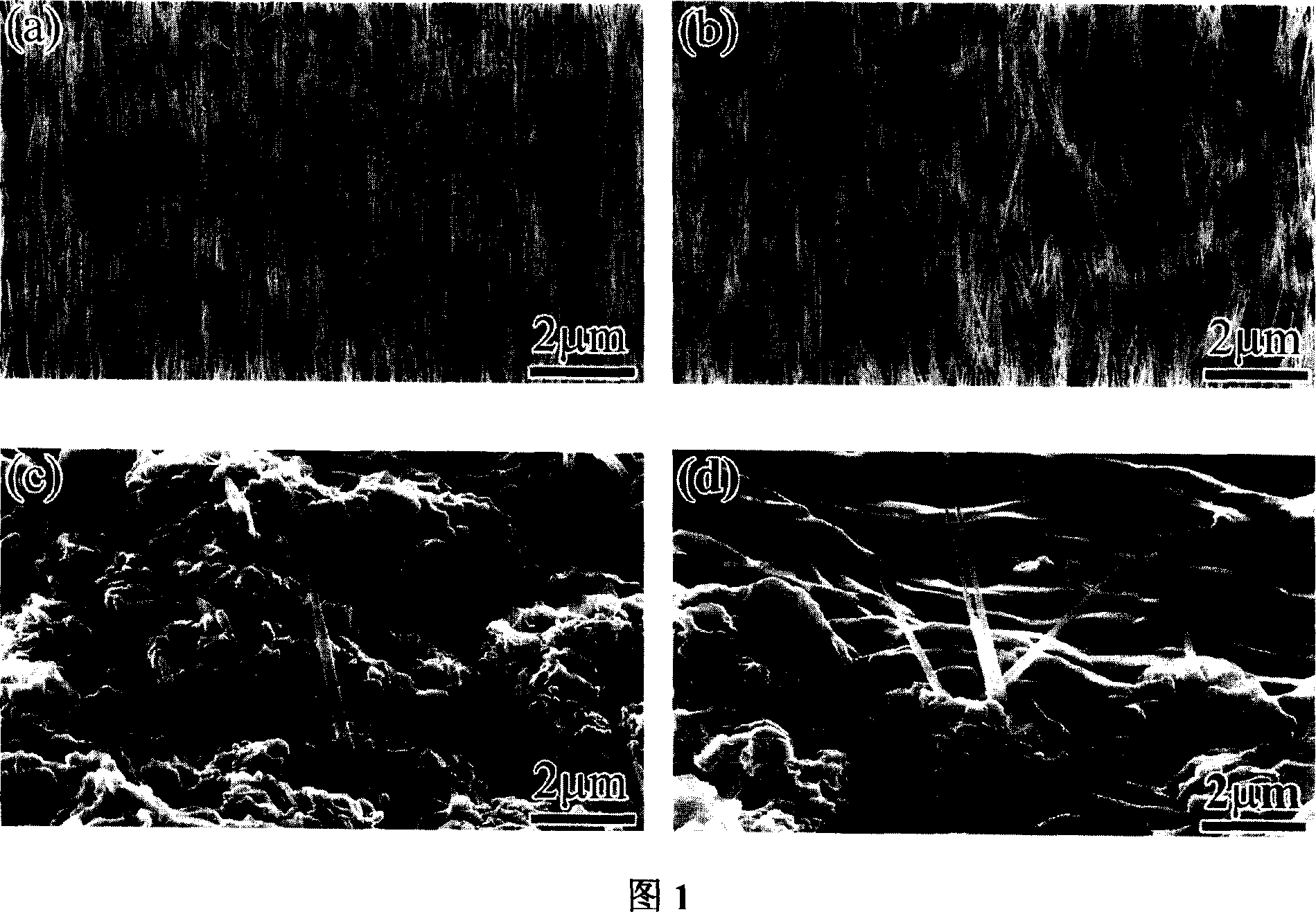

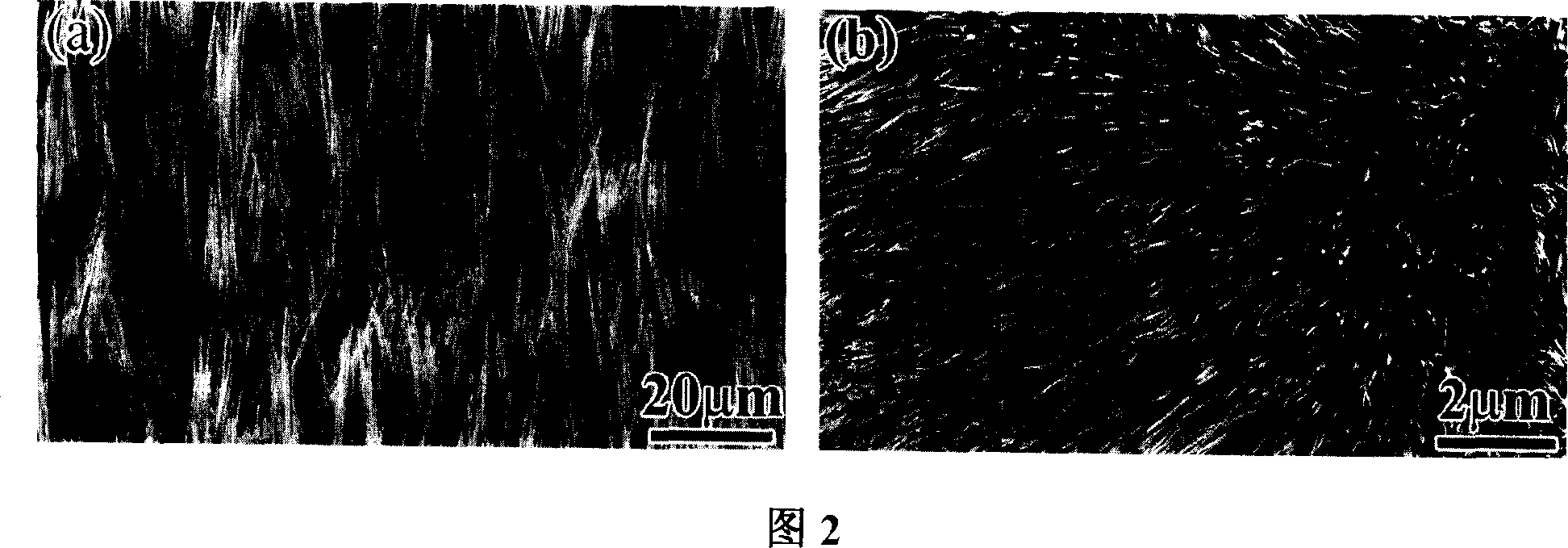

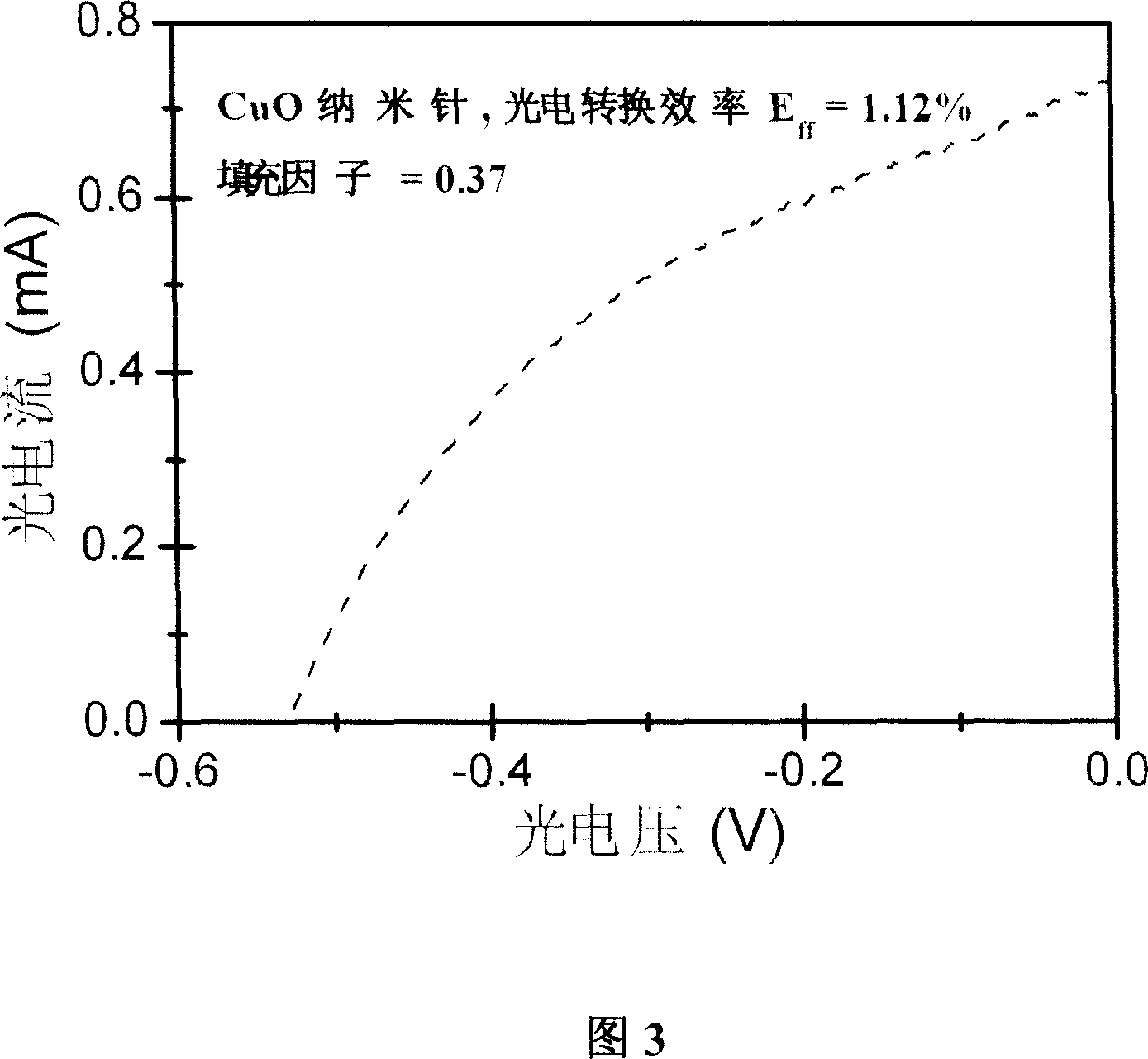

[0015] (1) Using pulse electrodeposition technology, adopting pulse electrodeposition parameters with output pulse frequency f of 100 Hz and duty cycle r of 10%, electrodeposit a layer of nanocrystalline Cu thin film on the surface of metal Cu substrate; (2) The Cu film was heated in air at different heating temperatures (700°C, 800°C, 900°C, 1000°C) for 1-2 hours, and thermally oxidized to prepare one-dimensional CuO nanoneedles. The results of the scanning electron microscope (SEM) experiment are shown in Figure 1 (in the figure (a) 700°C; (b) 800°C; (c) 900°C; (d) 1000°C); (3) the one-dimensional CuO nanoneedle material / Cu substrate prepared at a heating temperature of 700°C As the cathode material of dye solar cell (the SEM experiment result of cathode material is shown in accompanying drawing 2), TiO 2 Nanocrystalline materials are used as anode materials, and after bipyridyl ruthenium dye (N 3 , (Bu 4 N) 2 Ru(dcbpyH) 2 (NCS) 2 ) of absolute ethanol solution sensitiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com