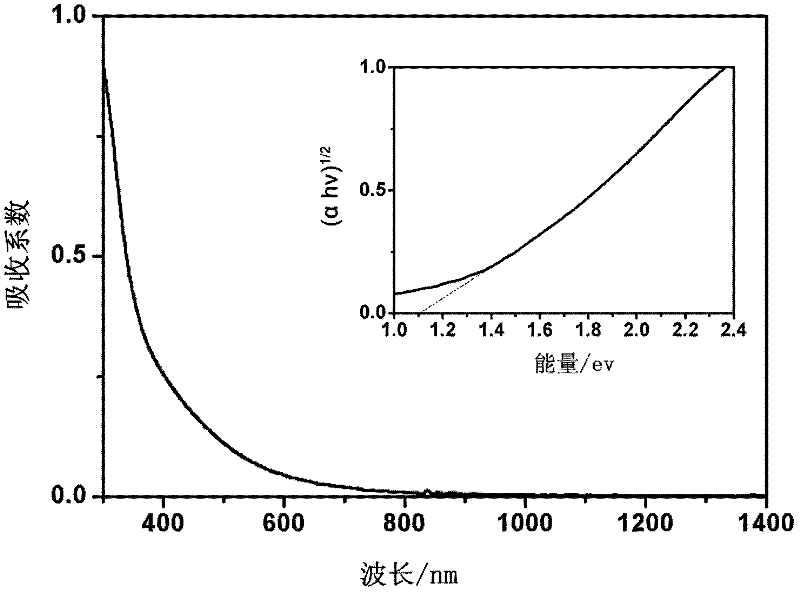

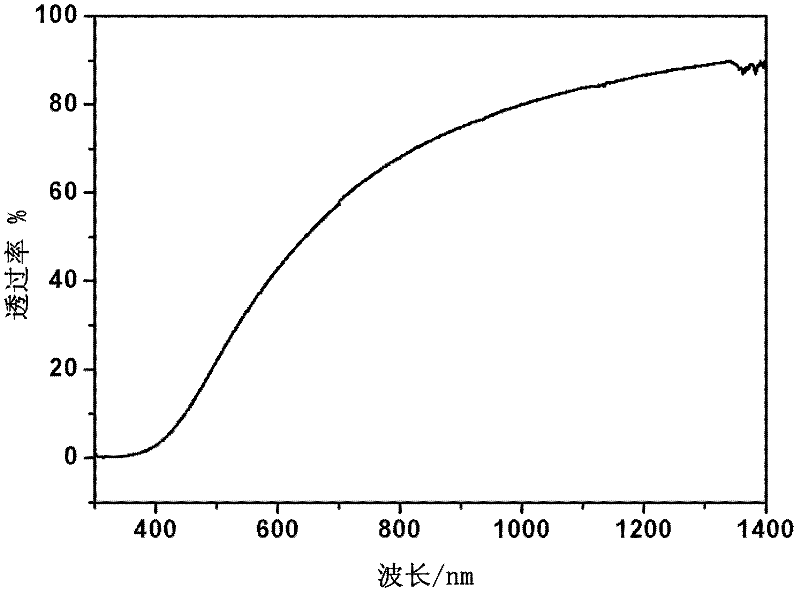

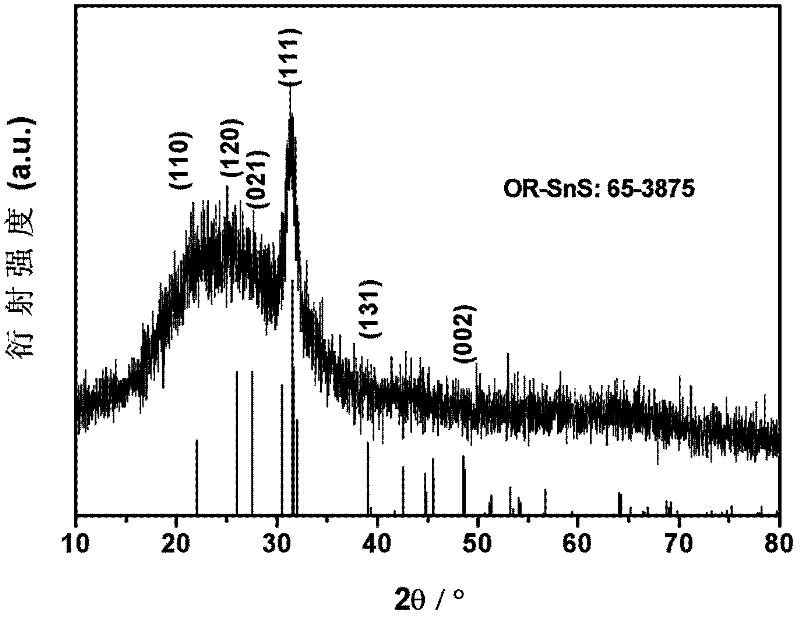

SnS nanocrystalline thin film preparation method

A nanocrystalline and thin-film technology, applied in the field of solar cells, can solve the problems of uncontrollable crystal nuclei formation and growth rate, inability to realize industrialized production, rare multi-component compounds, etc., and achieve accurate and easy-to-control stoichiometric ratio of thin films with low cost , film dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of SnS nanocrystal solution:

[0036] 0.2256g stannous chloride dihydrate (SnCl 2 ·H 2 0) dissolved in 10ml of diethylene glycol, under magnetic stirring, completely dissolved, as the tin source precursor solution; 0.07513g thioacetamide CH 3 CSNH 2 , 0.1g polyvinylpyrrolidone (PVP), 0.25ml hydrazine hydrate is dissolved in the diethylene glycol of 40ml, under magnetic stirring, dissolves completely, as sulfur source precursor solution; Insert a thermometer into the three-necked flask of the reflux tube, pass in nitrogen as a protective gas, and heat to 180°C; then transfer the tin source precursor solution to a syringe, then inject it into the three-necked flask to initiate the reaction, reflux at 180°C, and keep warm for 20 minutes After that, quickly place it in a water bath, cool to room temperature, and make a SnS nanocrystal solution;

[0037] The diethylene glycol is a solvent, polyvinylpyrrolidone is a dispersant, and hydrazine hydrate is an ...

Embodiment 2

[0047] Example 2 is basically the same as Example 1, except that the addition of 0.25 ml of hydrazine hydrate during the preparation of the nanocrystals is replaced by the addition of 0.1 ml of triethanolamine (TEA).

Embodiment 3

[0049] Example 3 is basically the same as Example 1, except that the addition of 0.25 ml of hydrazine hydrate during the preparation of the nanocrystals is replaced by the addition of 0.1 ml of ammonia water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com