Nanocrystalline film and its low temperature preparing method

A nanocrystalline and thin film technology, which is applied in the field of nanocrystalline precursor thin film with graded structure and its low-temperature chemical sintering preparation, to achieve the effects of reasonable structure design, cost saving, and good transmission of photogenerated electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029]The preparation method of DSSC in the example: dry the prepared titanium oxide thin film electrode under the condition of 100 ° C for a certain period of time, then immerse the electrode in the ethanol solution of N719 dye for 8 hours, take it out, rinse it with absolute ethanol and let it dry Dye-sensitized titanium oxide film electrodes can be made after drying; the prepared sensitized electrode is used as the working electrode, and the platinum-plated conductive substrate is used as the counter electrode, and the electrode containing 0.5M LiI, 0.05MI 2 and 0.5M tetra-tert-butylpyridine in acetonitrile solution as electrolyte, assembled into a "sandwich" structure of DSSC.

[0030] Photoelectric test method of DSSC in the example: The photoelectric performance measurement of the cell was measured at room temperature using a computer-controlled Oriel sunlight simulation system. The incident light intensity is 100mW / cm 2 , the illuminated area is 0.23cm 2 .

Embodiment 1

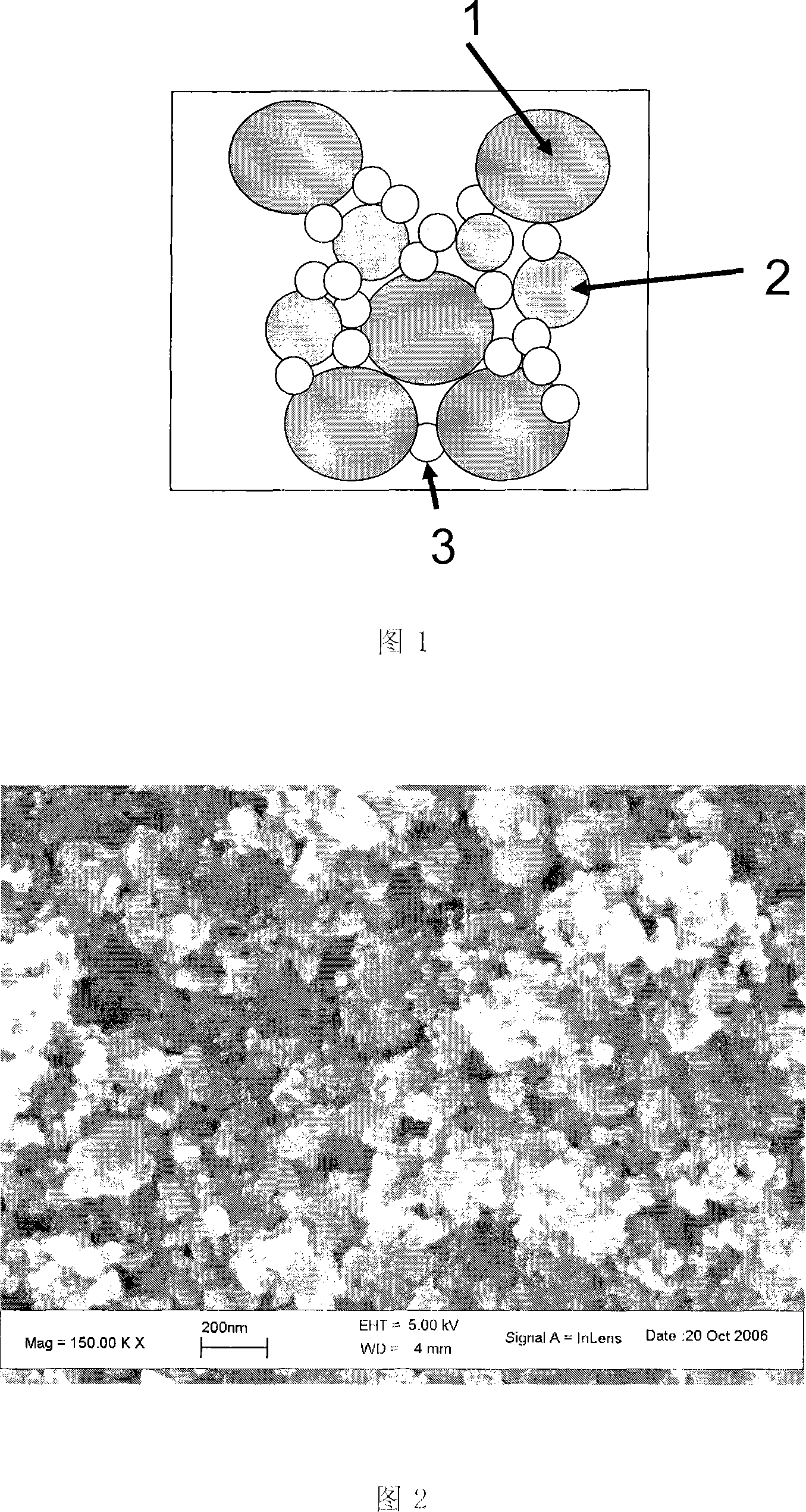

[0032] The smallest size nanocrystalline particles used to connect the large particles are first prepared. Using titanium alkoxide (tetrabutyl titanate) as titanium source, take 125mL tetrabutyl titanate and hydrolyze it in 750mL nitric acid solution with pH=1, stir at 80°C until the solution is clear, transfer these solutions to the reaction In the kettle, the sol of titanium oxide was prepared by hydrothermal reaction method; the reaction temperature was 210°C, the reaction time was 12 hours, and anatase-type titanium oxide particles with a particle size of 13nm were prepared; the surface of nanoparticles prepared by this method Adsorbed a large number of hydroxyl groups and H 2 O molecules;

[0033] Thereafter a graded slurry is prepared. Mix commercial titanium oxide nanocrystalline powder (P25, with an average diameter of 25nm) particles and titanium oxide particles with a size above 100nm in ethanol solution, the mass ratio of the two particles is 2.5:1; mix 10nm The ...

Embodiment 2

[0036] The preparation method of the graded structure slurry is the same as that of Example 1, and at last, an oxide film is prepared on a conductive plastic substrate (PEN, polyethylene glycol diformate, square resistance 13Ω, light transmittance 80%) by a scraper coating method. Titanium film, and treated at 150 ° C for 5 minutes, the surface hydroxyl groups between the particles in the film will be dehydrated, thereby preparing a porous titanium oxide film, the specific surface area of the film is 57m 2 / g, the porosity is 29%, the film is assembled into DSSC, and its photoelectric performance is measured, and the short circuit current density is 12.6mA / cm 2 , the open circuit voltage is 0.750V, the photoelectric conversion efficiency is 5.95%, and the fill factor is 0.63.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com