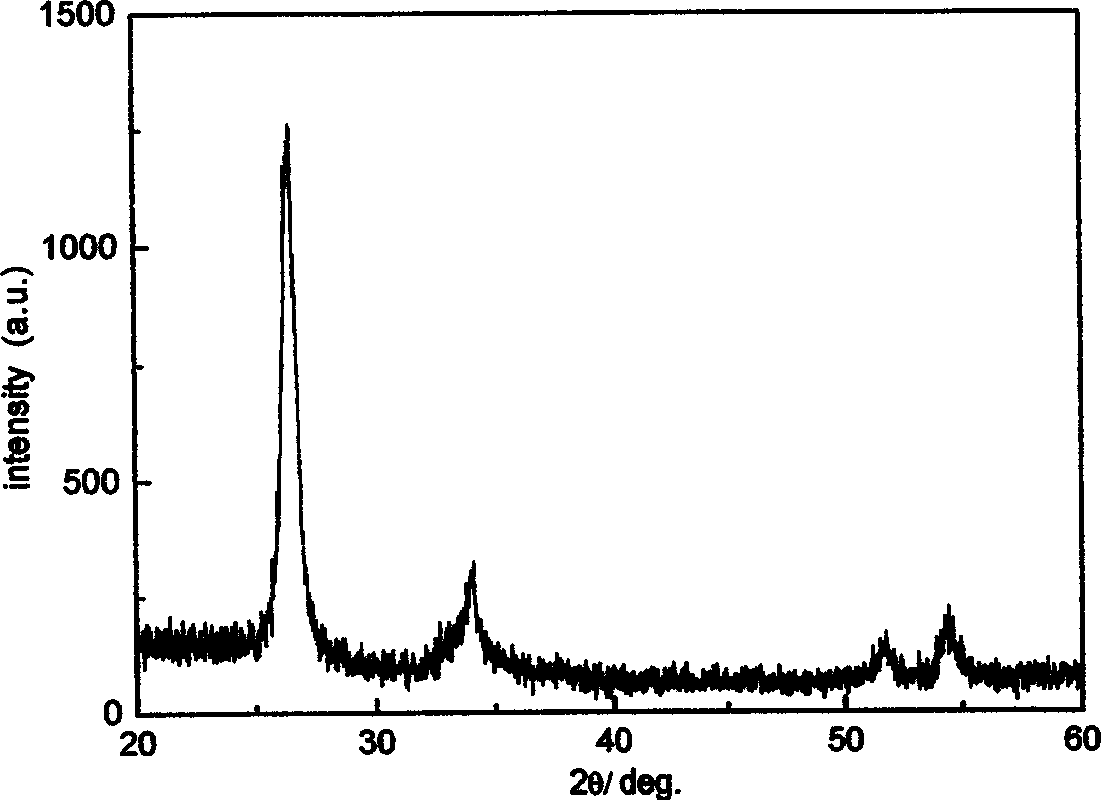

Process for preparing tin oxide nanocrystalline thin films

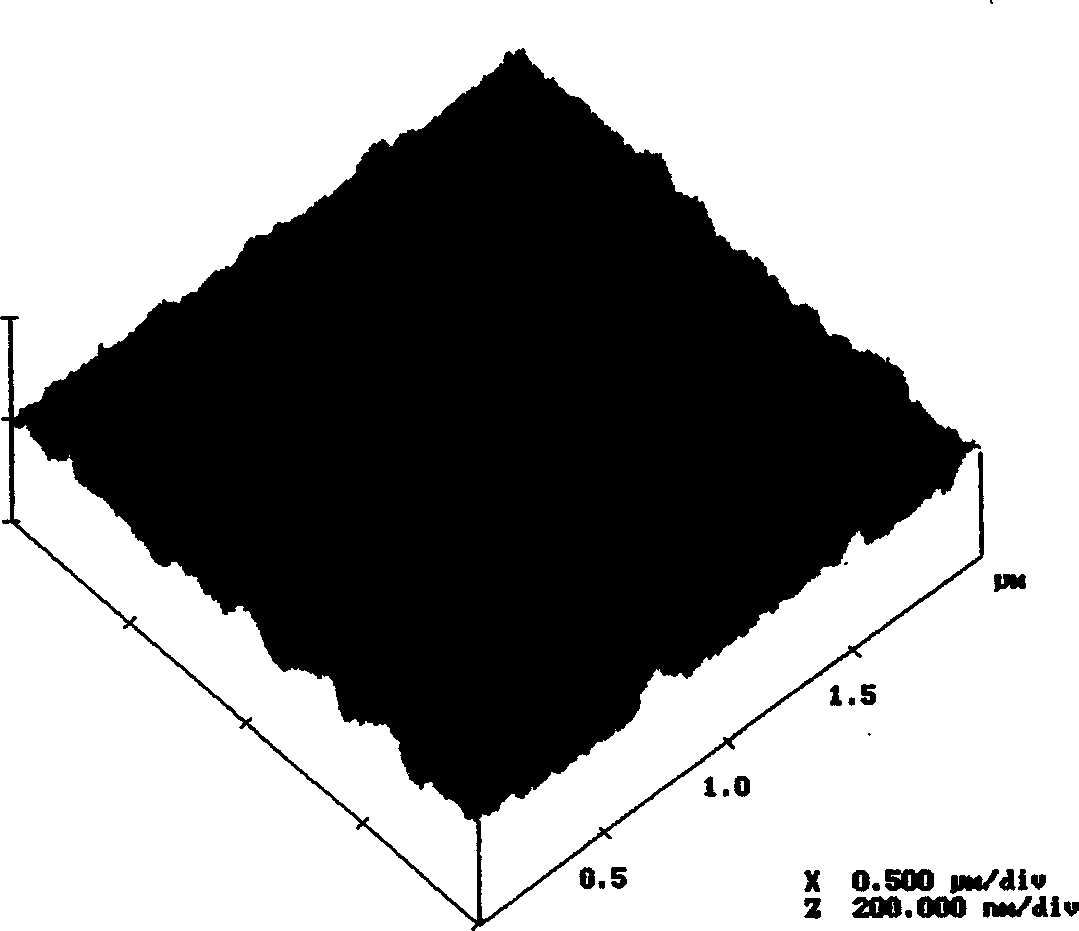

A technology of tin dioxide and nanocrystals, which is applied in semiconductor/solid-state device manufacturing, liquid chemical plating, coating, etc., can solve the problems of high preparation cost, complicated technical process, and large energy consumption, and achieve a dense and uniform film surface , broad application prospects, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Place the single crystal silicon in distilled water and absolute ethanol for ultrasonic cleaning to wash away the floating dust and organic impurities on the surface; place the clean surface of the single crystal silicon wafer in a mixed solution of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 3:1 Medium immersion treatment, soaking at 80°C for 20 minutes, the treated substrate was washed with deionized water and isopropanol respectively, blown dry under nitrogen atmosphere, and vacuum dried at 100°C for 40 minutes; use 6.5×10 -3 The anhydrous cyclohexane solution of M mercaptopropyltrimethoxysilane soaked the treated substrate for 30 minutes, washed it with chloroform and deionized water successively after taking it out, and purged and dried it under nitrogen; then put the treated substrate in a volume ratio Soak in a 1:5 solution of hydrogen peroxide and acetic acid at 40°C for 60 minutes; then rinse the substrate with deionized water and chl...

Embodiment 2

[0020] Put the glass in distilled water and acetone and ultrasonically wash it to wash away the floating dust and organic impurities on the surface; put the clean glass piece in the mixed solution of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 2:1 for soaking treatment at 85°C After soaking for 40 minutes, the treated substrate was washed with deionized water and isopropanol respectively, dried in a helium atmosphere, and vacuum-dried at 90°C for 10 minutes; with 1×10 -3 The benzene solution of M-mercaptododecyltrimethoxysilane soaks the treated substrate for 1 hour, washes it with chloroform and deionized water successively after taking it out, and blows and dries it under helium; then put the treated substrate in a volume ratio of soak in a 1:3 hydrogen peroxide and acetic acid solution at 50°C for 5 minutes; then rinse the substrate with deionized water and chloroform, and dry it with helium. Finally put that base into a 2×10 -3 M SnCl4 / 0.2M HC...

Embodiment 3

[0022] Put alumina as the substrate in distilled water for ultrasonic cleaning to wash away the floating dust and organic impurities on the surface; put the clean alumina substrate in a mixed solution of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 1.5:1 for soaking treatment , soaked at 95°C for 25 minutes, the treated substrate was washed with deionized water and isopropanol respectively, dried under argon atmosphere, and vacuum-dried at 120°C for 20 minutes; -2 Soak the substrate in toluene solution of M vinyltrimethoxysilane for 2 hours, wash it with chloroform and deionized water in turn after taking it out, and blow and dry it under argon; then place the treated substrate in saturated potassium hydrogen persulfate solution immersion at 50°C for 5 minutes; then the substrate was rinsed with deionized water and chloroform, and dried with argon. Finally put that base into a 3.5×10 -2 M SnCl 4 / 0.6M HCl solution for 3 days, with a pH value of 0.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com