Dye-sensitized solar battery of nano-crystalline thin film and method for making same

A technology of solar cells and dye sensitization, which is applied in the field of dye-sensitized nanocrystalline solar cells and its preparation, can solve problems such as unsatisfactory interfacial contact, and achieve the effects of improving photoelectric conversion efficiency, interfacial contact and interfacial reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

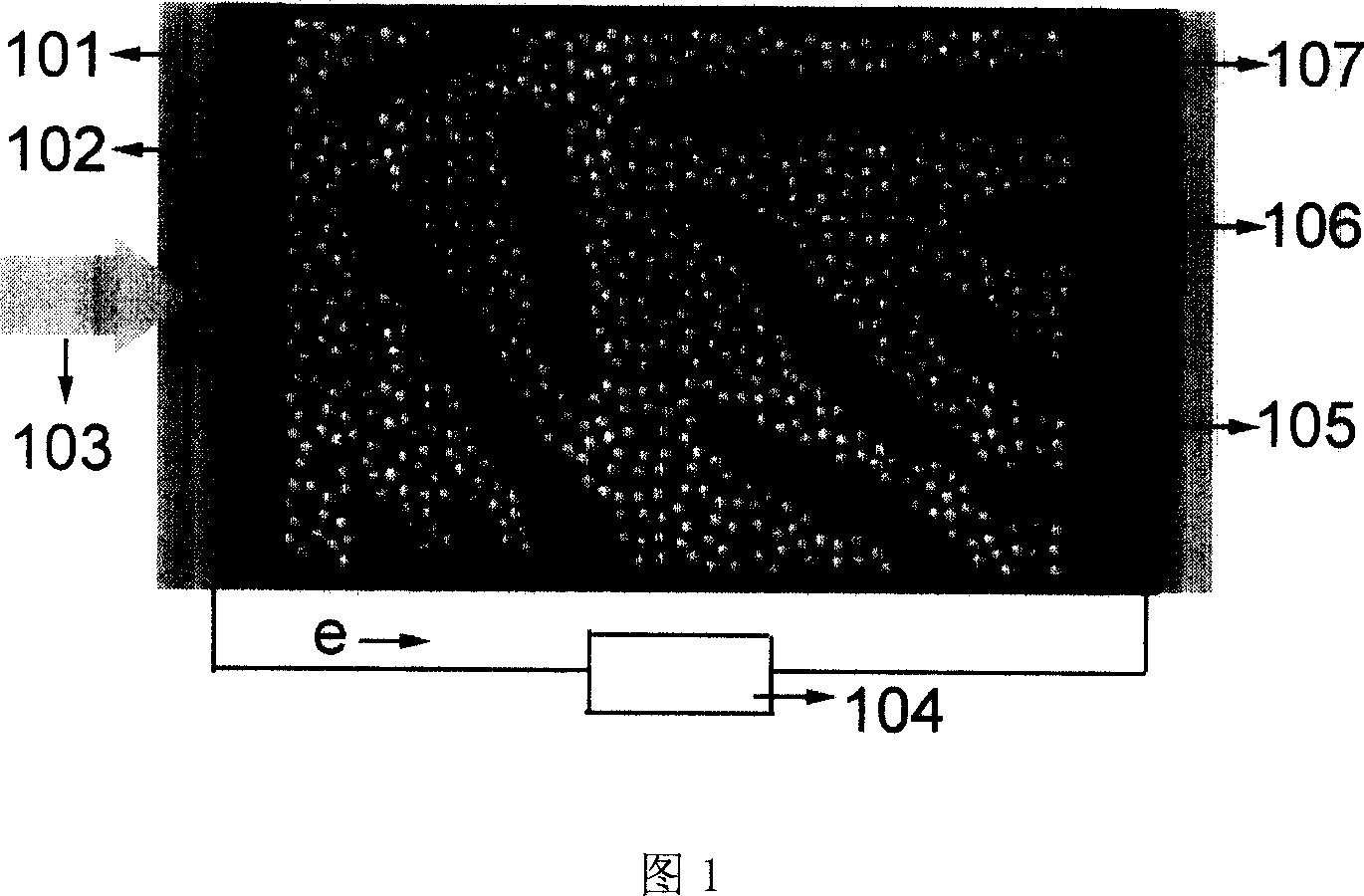

Image

Examples

Embodiment 1

[0019] Mix 165 mg of zinc oxide nanowires with 10 ml of 120 g / L nano-titanium dioxide colloidal dispersion evenly. Then the colloid was coated on the dense titanium dioxide film, baked at 450° C. for 30 minutes, and the coating and firing process was repeated until a nano-sized titanium dioxide crystal film with a thickness of 10 microns was obtained. This thin film electrode was immersed in hot (75°C) 0.5 mol / L hydrochloric acid solution for 48 hours until the ZnO nanowires were completely removed. Soak the electrode in a titanium tetrachloride solution, then bake it at 450°C for 15 minutes, and then place the electrode at 3×10 -4 Sensitization by soaking in mol / L Z907 dye in acetonitrile and butanol solution for 12 hours.

[0020] The dye-sensitized titanium dioxide nanocrystalline film prepared above is used as the cathode, the conductive glass coated with the platinum layer is used as the counter electrode, and a quasi-solid electrolyte is used to assemble the battery. T...

Embodiment 2

[0025] Mix 100 mg of aluminum hydroxide nanorods with 10 ml of 100 g / L nano-titanium dioxide colloidal dispersion evenly. Then the colloid was coated on the dense titanium dioxide film, baked at 600° C. for 10 minutes, and the coating and firing process was repeated until a nano-sized titanium dioxide crystal film with a thickness of 15 microns was obtained. This thin film electrode was immersed in hot (75°C) 0.5 mol / L NaOH solution for 40 hours until the AlOH nanorods were completely removed. The electrode was soaked in a titanium tetrachloride solution, and then baked at 300°C for 40 minutes, and then the electrode was heated at 10 -5 Sensitize by immersing mol / L N3 dye in acetonitrile and butanol solution for 20 hours.

[0026] The dye-sensitized titanium dioxide nanocrystalline film prepared above was used as the cathode, the conductive glass coated with platinum was used as the counter electrode, and a liquid electrolyte was used to assemble the battery. The liquid elec...

Embodiment 3

[0030] Mix 50 mg of iron oxide nanowires with 10 ml of 120 g / L nano-titanium dioxide colloidal dispersion evenly. Then the colloid was coated on the dense titanium dioxide film, baked at 350° C. for 30 minutes, and the coating and firing process was repeated until a nano-sized titanium dioxide crystal film with a thickness of 10 microns was obtained. This thin film electrode was immersed in hot (75°C) 0.5 mol / L hydrochloric acid solution for 48 hours until the iron oxide nanowires were completely removed. The electrode was soaked in a titanium tetrachloride solution, and then baked at 400 °C for 30 minutes, and then the electrode was heated at 10 -5 Sensitization by immersion in mol / L N3 dye in acetonitrile and butanol solution for 8 hours.

[0031] The dye-sensitized titanium dioxide nanocrystalline film prepared above is used as the cathode, and the conductive glass coated with platinum layer is used as the counter electrode, and a quasi-solid electrolyte is used to assembl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com