Blanket type light anode for dye sensitized solar cell and preparation method thereof

A technology of solar cells and dye sensitization, which is applied to the photoanode of dye-sensitized solar cells and its preparation field, which can solve the problem of ineffective separation of photogenerated electrons and holes, restricting the photoelectric conversion efficiency of dye-sensitized solar cells, and limiting the fast Migration and other issues to achieve the effect of improving photoelectric conversion efficiency, reducing grain boundary energy barrier, and reducing dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

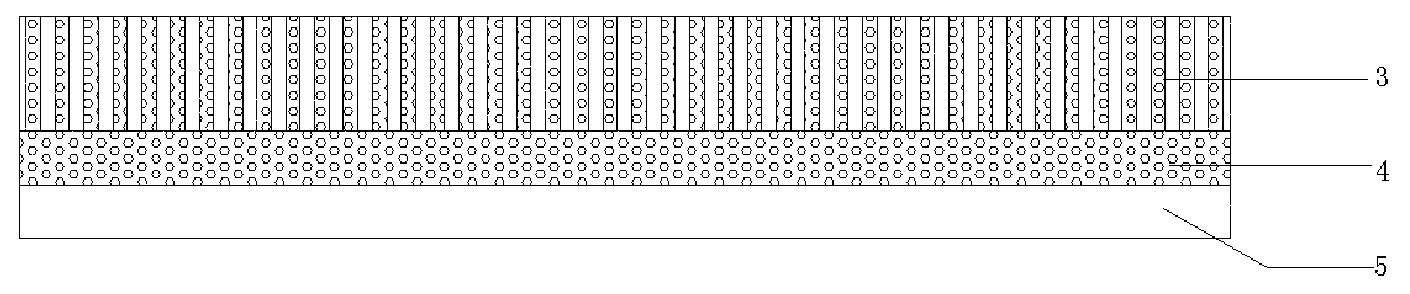

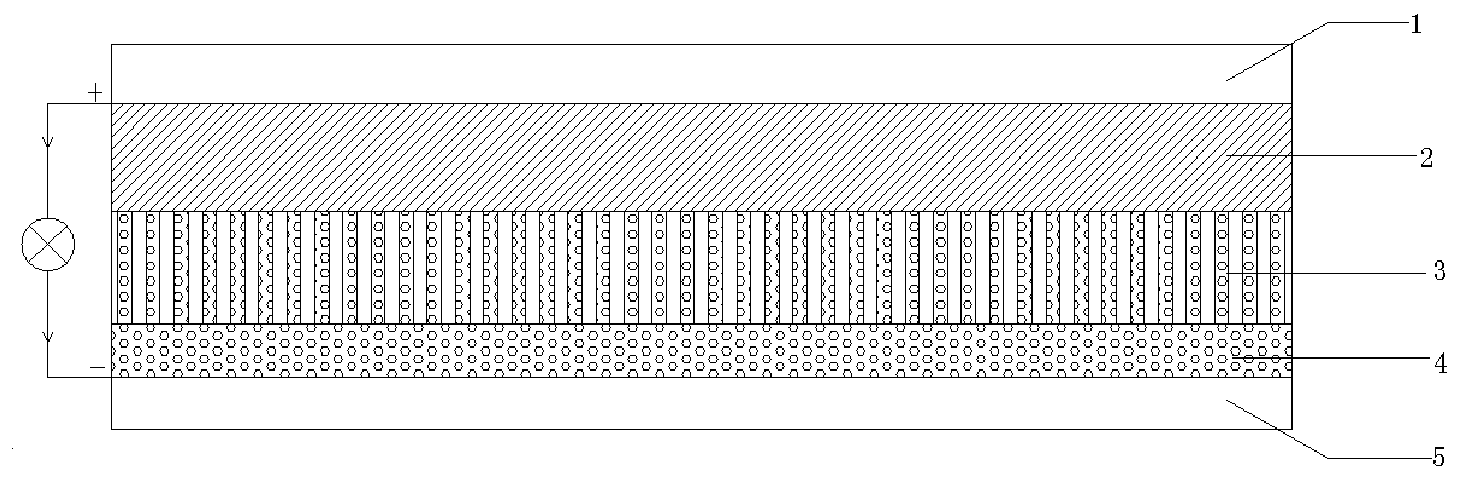

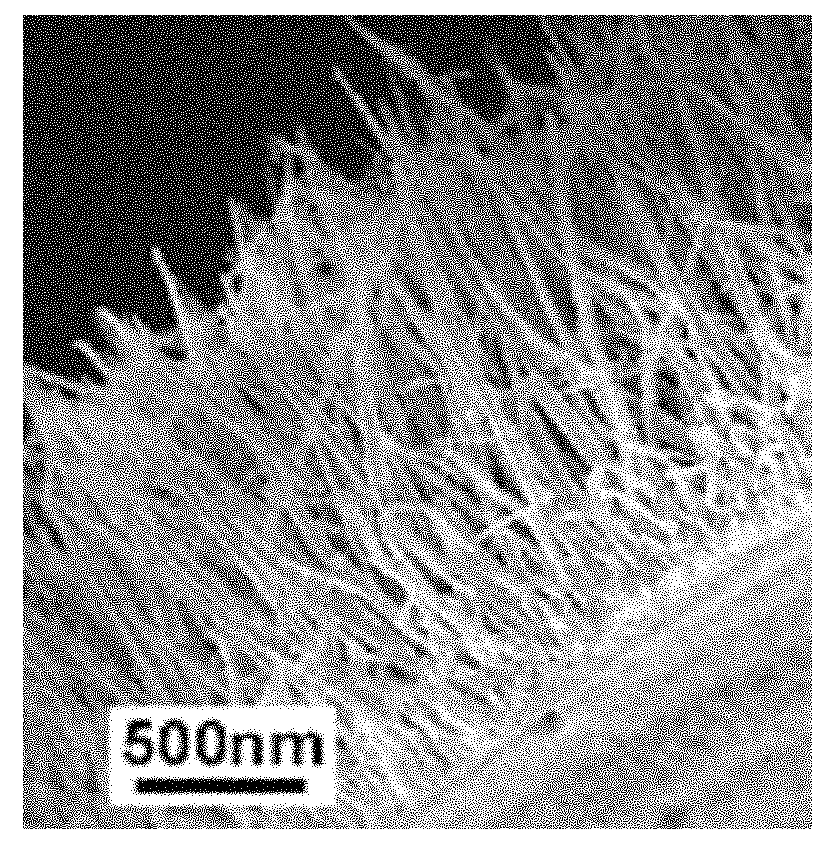

[0026]Put the high-purity titanium plate into 8M NaOH solution at 150°C and react for 24 hours to prepare a titanium-based titanate nanowire array film, and put the resulting titanium-based titanate nanowire array film into 0.05mol / L Fully soak in dilute hydrochloric acid until the white film on the surface is separated from the substrate to obtain a titanate nanowire array film; apply a layer of sticky P25 titanium oxide colloid on the surface of the transparent conductive glass by scraping, and then coat the titanate nanowires The array film is bonded to the surface of titanium dioxide colloid, after drying, it is sintered at 300°C for 50 minutes to obtain a composite film of porous titanium dioxide nanocrystalline film and titanium dioxide nanowire array film; finally, the composite film is soaked in 4×10 -4 mol / L dye in an organic solution for 8 hours to obtain the final carpet photoanode for dye-sensitized solar cells.

[0027] The prepared dye-sensitized solar cell carpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com