Photoelectric device with colloid NiO nanocrystalline film as hole transport layer and manufacturing method thereof

A hole transport layer, optoelectronic device technology, applied in semiconductor/solid-state device fabrication, organic light-emitting device fabrication/processing, organic semiconductor device fabrication/processing, etc. devices, etc., to achieve the effect of cost saving and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

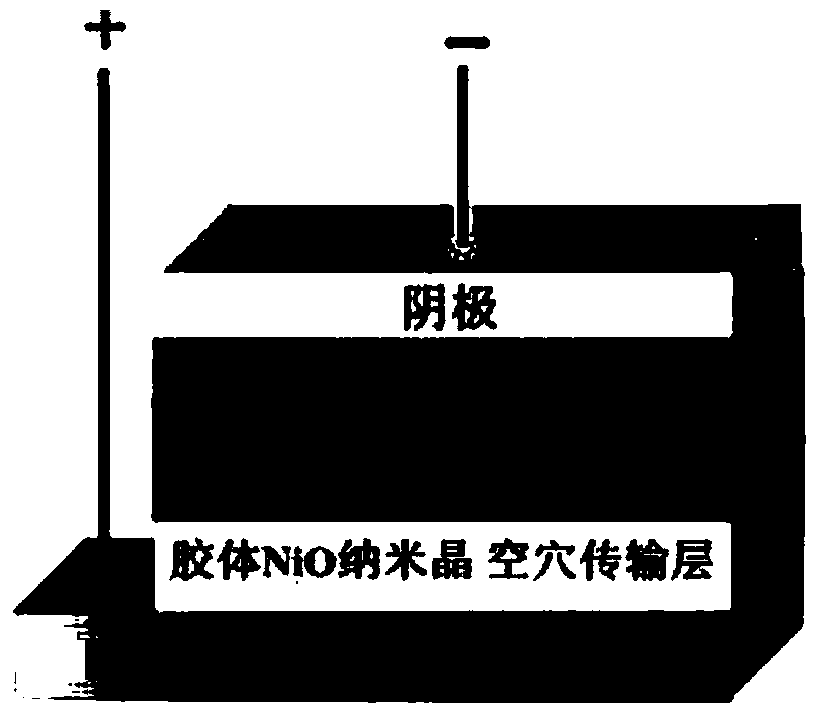

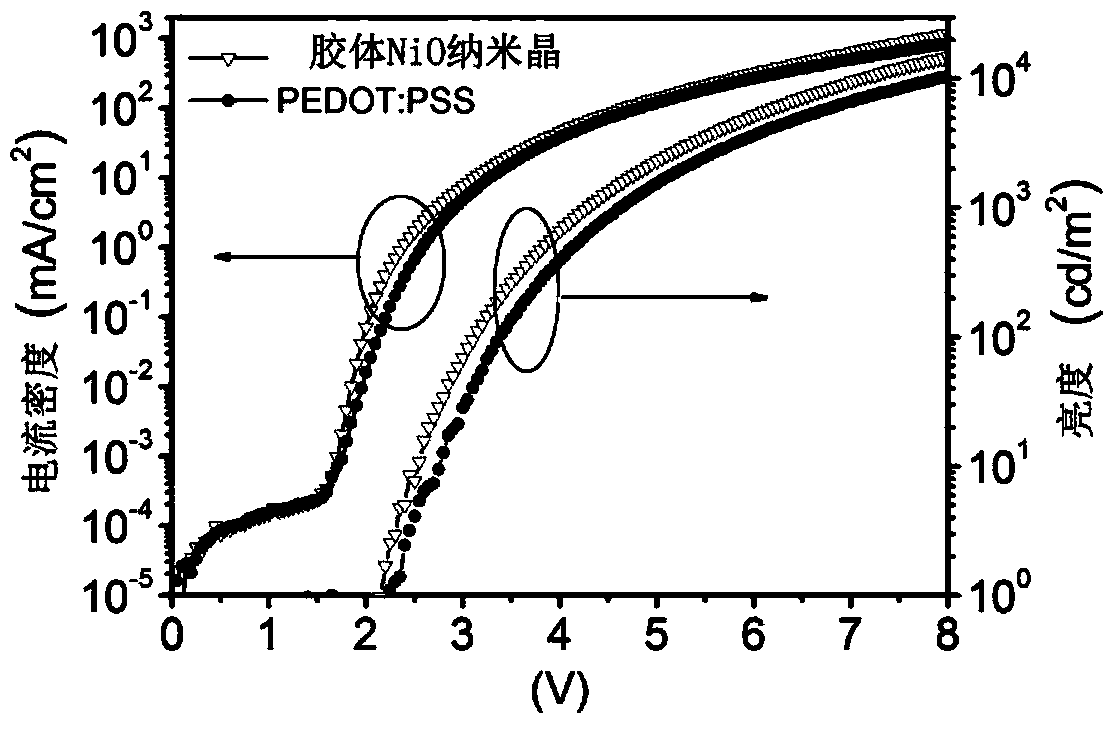

[0043] Example 1 Flexible organic LED device using colloidal NiO nanocrystalline thin film as hole transport layer

[0044] 1) Add 1mmol of nickel stearate, 0.2mmol of lithium stearate, and 6mmol of stearyl alcohol into 10ml of 1-octadecene, put it into a 50ml flask, heat up to 80°C under the protection of an inert gas, and pump Vacuum for 30 minutes; under the protection of inert gas, heat up to 280°C and keep warm for 120 minutes, cool to room temperature, add precipitant ethanol and centrifuge to obtain colloidal NiO nanocrystals;

[0045] 2) Mix 20 mg colloidal NiO nanocrystals with 0.5 ml chloroform to obtain a colloidal NiO nanocrystal solution, which is spin-coated on an ITO / PET substrate (commercially available) at a speed of 3000 Rpm / min to form a uniform and flat film, and then Annealed in air at 90°C for 120 minutes, and then treated with ozone for 10 minutes to obtain a colloidal NiO nanocrystalline film on the substrate;

[0046] 3) Mix 14mg MEH-PPV (manufacturer...

Embodiment 2

[0055] Example 2 Flexible organic LED device using colloidal NiO nanocrystalline thin film as hole transport layer

[0056] 1) Mix 15 mg of the colloidal NiO nanocrystals prepared in Example 1 with 0.5 ml of hexane to obtain a colloidal NiO nanocrystal solution, which is spin-coated on the ITO / PET flexible substrate at a speed of 1500 Rpm / min to form a uniform and flat The film was then annealed in air at 90°C for 140 minutes, and then treated with ozone for 10 minutes to obtain a colloidal NiO nanocrystalline film on the substrate;

[0057] 2) Mix 16mg MEH-PPV with 1ml dichlorobenzene to obtain a solution of MEH-PPV luminescent material, and spin-coat it on the colloidal NiO nanocrystalline film obtained in step 2) at a speed of 1500 Rpm / min to form a MEH-PPV luminescent layer ;

[0058] 3) ZnO thin film was prepared by thermal evaporation on the MEH-PPV light-emitting layer as an electron transport layer;

[0059] 4) Preparation of metal Al cathode on ZnO film.

[0060] T...

Embodiment 3

[0061] Example 3 Flexible organic solar cell using colloidal NiO nanocrystalline thin film as hole transport layer

[0062] 1) Mix 60 mg of colloidal NiO nanocrystals prepared in Example 1 with 1 ml of tetrachlorethylene to obtain a NiO nanocrystal solution, which is spin-coated on an ITO / PET substrate at a speed of 4000 Rpm / min to form a uniform and flat film, and then Annealed in air at 90°C for 120 minutes, and then treated with ozone for 10 minutes to obtain a colloidal NiO nanocrystalline film on the substrate;

[0063] 2) Add 20mg TQ1:PC 71 BM (manufacturer: Solenne) was mixed with 1ml of dichlorobenzene to obtain TQ1:PC 71 The solution of BM light-absorbing material was spin-coated on the colloidal NiO nanocrystalline film obtained in step 2) at a speed of 1200 Rpm / min to form TQ1:PC 71 BM light absorbing layer;

[0064] 3) In TQ1:PC 71 On the BM light absorbing layer, a ZnO thin film was prepared by thermal evaporation method as an electron transport layer;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com