A kind of polyurethane prepolymer and its preparation method and ultraviolet light curing polyurethane prepolymer composition

A polyurethane prepolymer and compound technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of production, negative impact on users, affecting the overall performance of coatings, and diluents that cannot be cured, etc., to achieve process optimization and human body The effect of stimulating green environmental protection and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a kind of preparation method of above-mentioned polyurethane prepolymer, comprising:

[0049] a) under the inert gas helium or argon, react the cyclocarbonate compound and the amine compound under the action of a catalyst at 50-150° C. for 5-48 hours to obtain the first reaction intermediate;

[0050] b) reacting the first reaction intermediate obtained in step a) and the acrylic compound at 100-120° C. for 2.5-3 hours in the presence of a polymerization inhibitor to obtain the polyurethane prepolymer;

[0051]Among them, the molar ratio of the cyclic carbonate compound, the amine compound and the acrylic compound is preferably (1-3):1:(2-3).

[0052] The cyclic carbonate compound in step a) is preferably ethylene carbonate, 1-methoxy-ethylene carbonate or propylene carbonate, more preferably propylene carbonate. The amine compound is preferably N-(2-hydroxyethyl)ethylenediamine, diamine or triamine, wherein the diamine is preferably...

Embodiment 1

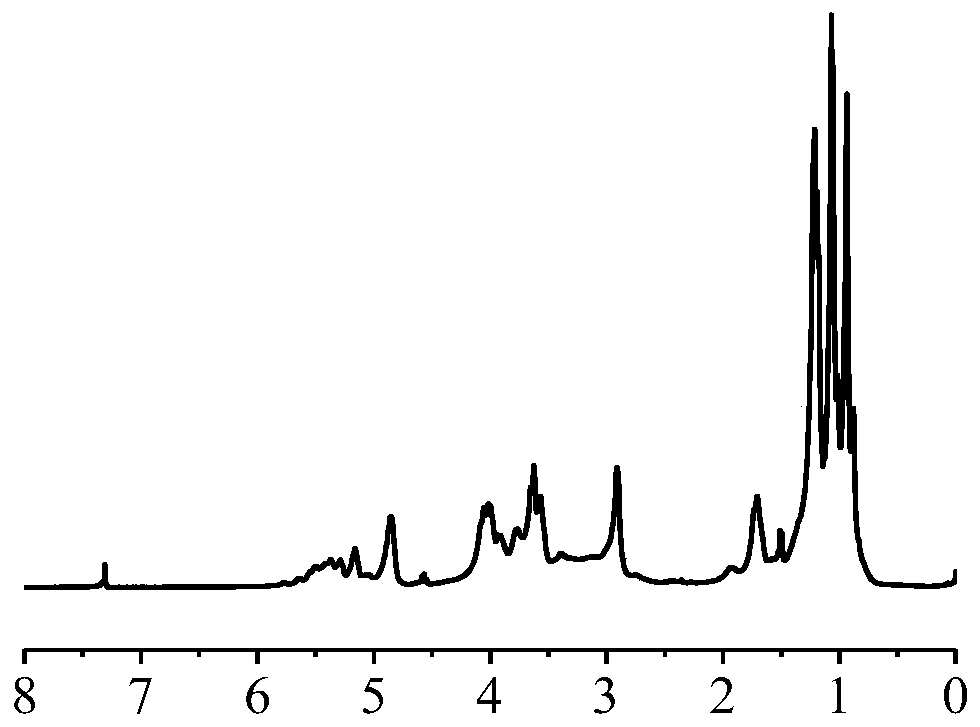

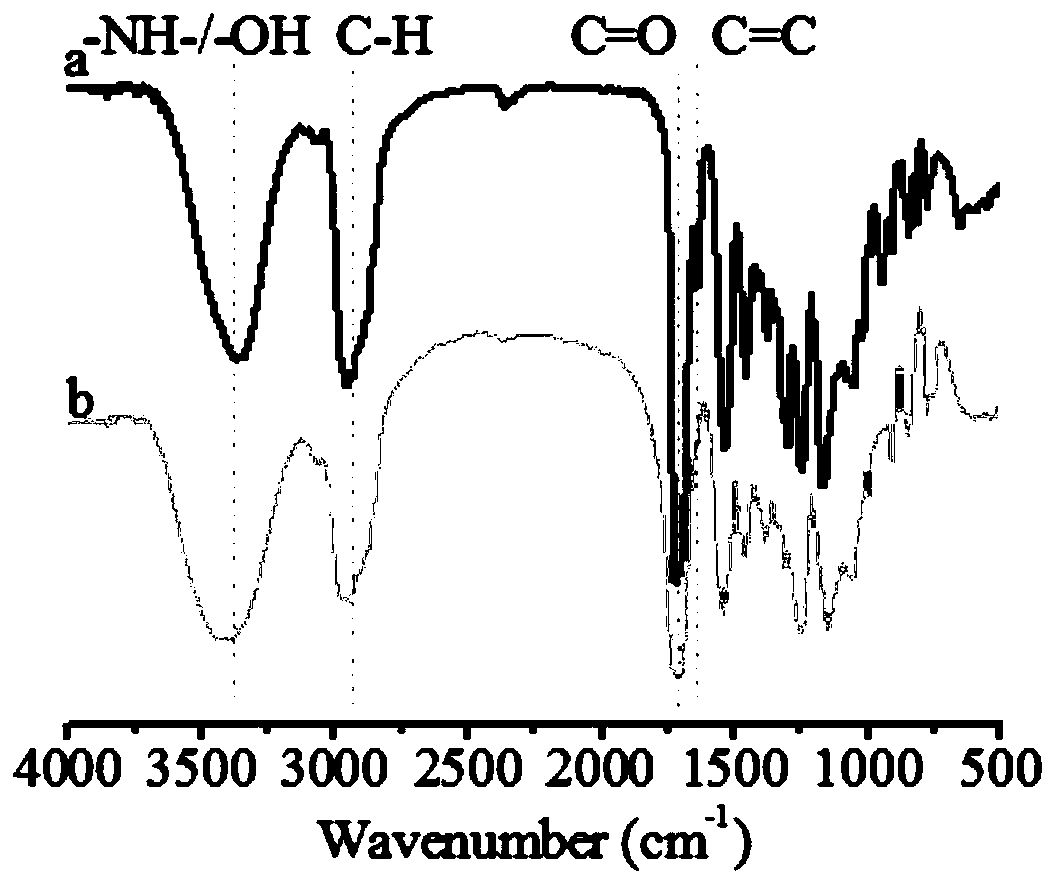

[0060] Nitrogen was passed into the four-necked flask with a stirrer and a thermometer to remove the air in the system, and after slowly raising the temperature to 150°C, 204.18g of propylene carbonate (PC) and 0.02g of cesium carbonate catalyst were added and stirred evenly, and then slowly Add 170.03 g of isophorone diamine dropwise, and keep the reaction for 5 hours to obtain a reaction intermediate. When the temperature of the above reaction system was lowered to 120°C, 284.3 g of glycidyl methacrylate containing 0.028 g of p-hydroxyanisole was slowly added dropwise to the system, stirred at constant temperature for 3 h, and then distilled under reduced pressure for 1.5 h to remove unreacted mono body, a light yellow polyurethane prepolymer was obtained, and its H NMR spectrum was as figure 1 shown.

[0061] Finally, the reaction system was cooled to 70° C., and 0.071 g of 2-isopropylthioxanthone and 0.08 g of phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide were added....

Embodiment 2

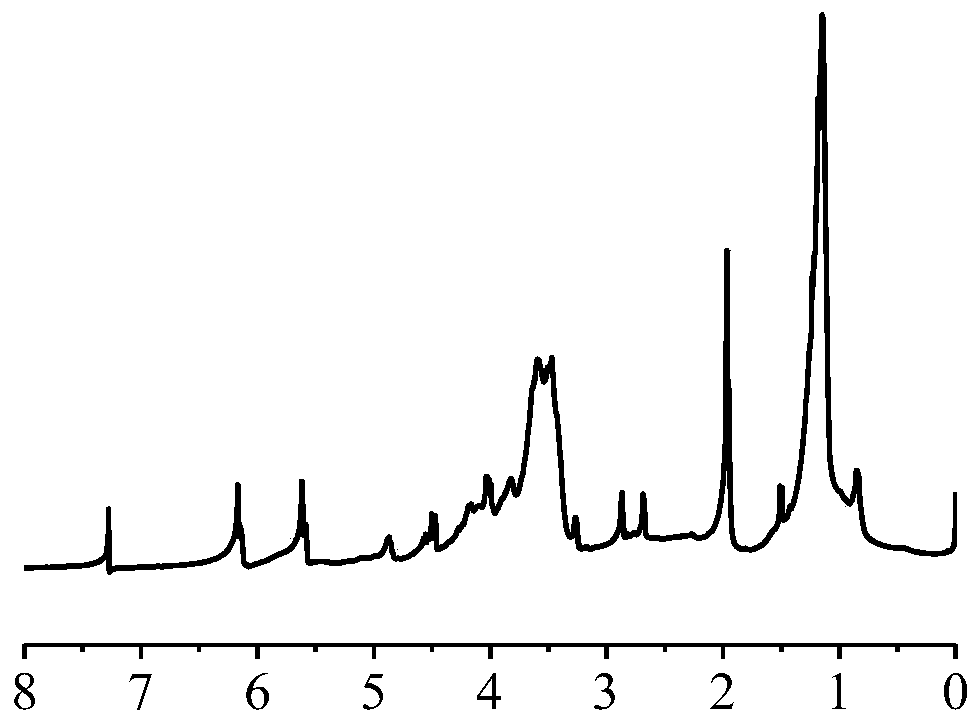

[0063] Nitrogen was passed into the three-necked flask with a stirrer and a thermometer to remove the air in the system, and the temperature was slowly raised to 50°C, then 1mol of PC and 0.014g of cesium carbonate catalyst were added and stirred evenly, and then 0.43mol of isofor was slowly added dropwise. Erketone diamine and 0.6mol of D-400 were incubated for 48 hours to obtain a reaction intermediate. Then, after the temperature of the reaction system was raised to 100° C., 1 mol of glycidyl methacrylate containing 0.025 g of hydroquinone was slowly added dropwise to the system, and stirred at constant temperature for 3 hours to obtain a light yellow polyurethane prepolymer.

[0064] Finally, the reaction system was cooled to 40°C, 0.23g of phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide was added, stirred at high speed for 5 minutes under dark conditions, and then stirred at low speed for 10 minutes to obtain a Transparent low viscosity UV curable polyurethane prepolymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com