Gas pipeline with high-sensitivity humidity detection device

A humidity detection device and gas pipeline technology, applied in the pipeline field, can solve the problems of not detecting water vapor, etc., achieve high repeatability, increase the humidity sensitivity performance, and solve the effect of performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

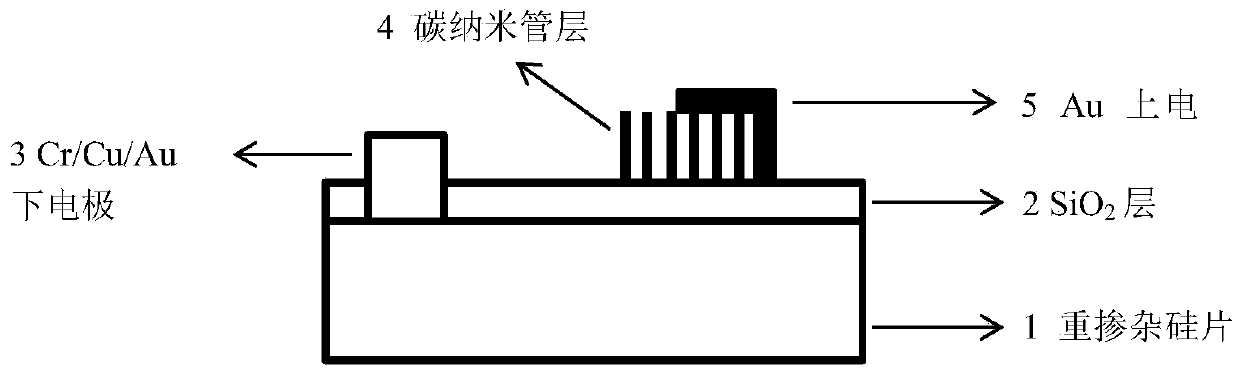

[0039] A gas pipeline with a high-sensitivity humidity detection device, the outside of the gas pipeline is equipped with a moisture-sensitive sensor module, the humidity-sensitive sensor module includes a heavily doped silicon chip arranged in sequence from bottom to top, close to the heavily doped SiO 2 layer, carbon nanotube layer, on SiO 2 The lower electrode between the layers and the upper electrode on the carbon nanotube layer grown on SiO 2 layer; there is a metal film on the lower electrode, and the metal film is an adhesive Cr layer, a conductive and thermally conductive Cu layer, and an Au layer as an electrode layer from the inside to the outside, and the Cr layer, Cu layer and The thickness of the Au layer is 70nm, 280nm and 300nm in sequence; the carbon nanotube layer adopts catalyst and / or photolithography to achieve its localized growth, and the grown carbon nanotube layer is modified by plasma to produce hydroxyl groups, The carbon nanotube layer has been tr...

Embodiment 2

[0058] A gas pipeline with a high-sensitivity humidity detection device, the outside of the gas pipeline is equipped with a moisture-sensitive sensor module, the humidity-sensitive sensor module includes a heavily doped silicon chip arranged in sequence from bottom to top, close to the heavily doped SiO 2 layer, carbon nanotube layer, on SiO 2 The lower electrode between the layers and the upper electrode on the carbon nanotube layer grown on SiO 2 layer; there is a metal film on the lower electrode, and the metal film is an adhesive Cr layer, a conductive and thermally conductive Cu layer, and an Au layer as an electrode layer from the inside to the outside, and the Cr layer, Cu layer and The thickness of the Au layer is 60nm, 400nm and 500nm in sequence; the carbon nanotube layer adopts catalyst and / or photolithography to achieve its localized growth, and the grown carbon nanotube layer adopts plasma to make it produce hydroxyl modification, The carbon nanotube layer has b...

Embodiment 3

[0077] A gas pipeline with a high-sensitivity humidity detection device, the outside of the gas pipeline is equipped with a moisture-sensitive sensor module, the humidity-sensitive sensor module includes a heavily doped silicon chip arranged in sequence from bottom to top, close to the heavily doped SiO 2 layer, carbon nanotube layer, on SiO 2 The lower electrode between the layers and the upper electrode on the carbon nanotube layer grown on SiO 2 layer; there is a metal film on the lower electrode, and the metal film is an adhesive Cr layer, a conductive and thermally conductive Cu layer, and an Au layer as an electrode layer from the inside to the outside, and the Cr layer, Cu layer and The thickness of the Au layer is 30nm, 270nm and 360nm in sequence; the carbon nanotube layer adopts catalyst and / or photolithography to achieve its localized growth, and the grown carbon nanotube layer adopts plasma to make it produce hydroxyl modification, The carbon nanotube layer has b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com