A kind of preparation method of macromolecular hydrogen bond composite fiber

A technology of macromolecules and composites, applied in spinning solution preparation, conjugated synthetic polymer artificial filament, wet spinning, etc., can solve problems such as uneven expansion, uneven composition, and uneven structure, and achieve Low equipment requirements, low cost, green and environmentally friendly preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Raw materials: PAA, relative molecular mass: 450KDa; PEO, relative molecular mass: 600kDa.

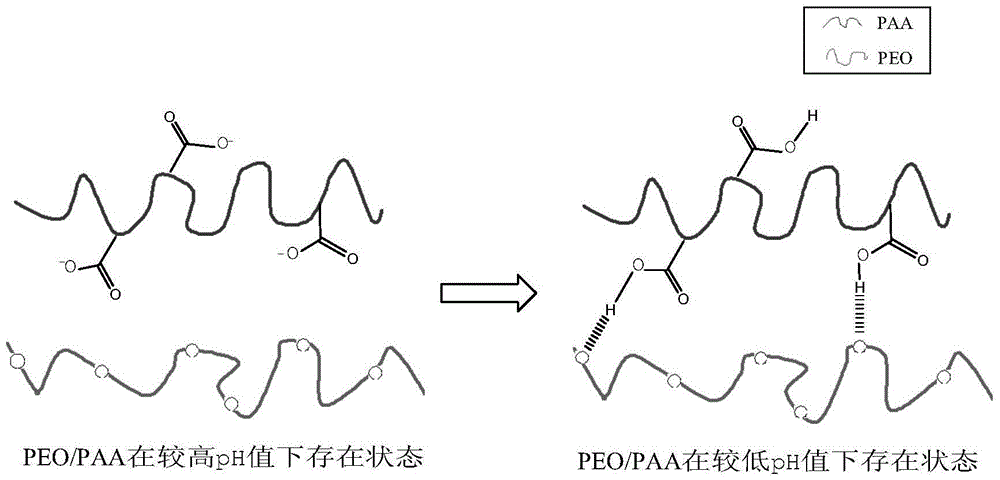

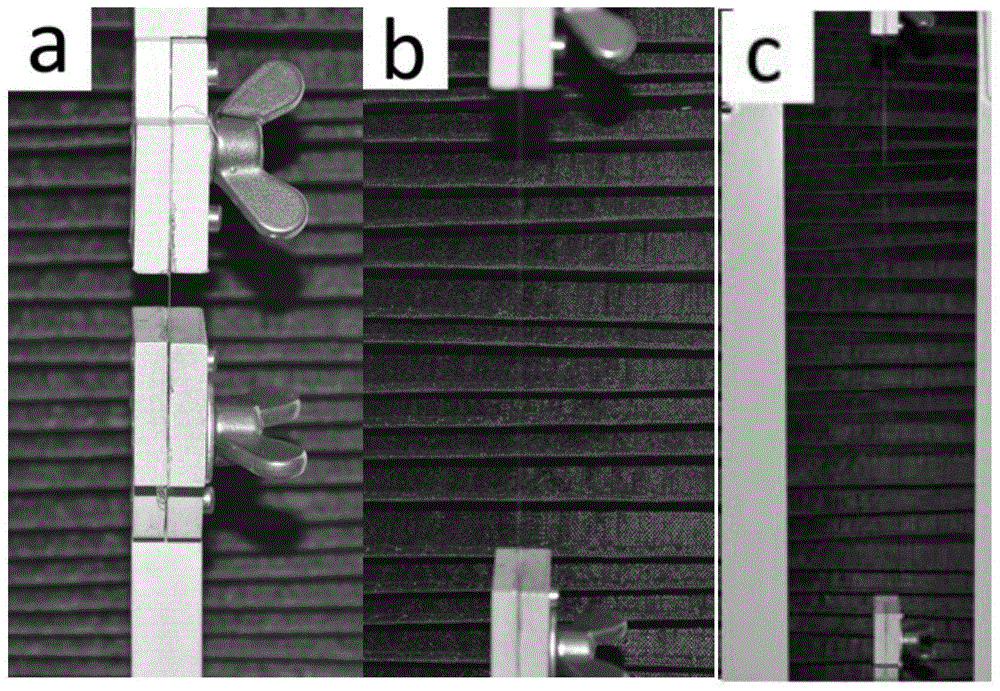

[0032] Add PAA and PEO to water respectively, and stir at a constant speed for 8 hours at room temperature to form an aqueous solution with a mass fraction of 8%, and mix them at a ratio of 1:1. Add NaOH solution dropwise to make a uniform and stable spinning solution; then filter (use a tank filter to filter, the filter cloth is made of polyester, the pore size of the filter material is 200 mesh, the filter cartridge is made of stainless steel, and the filter pressure is 0.1~ 0.5MPa), the spinning solution was degassed by centrifugation at 25°C for 45min at a speed of 4500r / min. Using the wet spinning process, a single-hole spinneret is used. The diameter of the spinneret hole is 0.08mm. The spinning liquid is extruded through the metering pump and the spinneret, and then enters an acidic coagulation bath at 25 ° C. The coagulation bath is pH = 1. hydrochloric acid solution to...

Embodiment 2

[0034] Raw materials: PAA, relative molecular mass: 450kDa; PEO, relative molecular mass: 600kDa.

[0035]Add PAA and PEO to dewatered water respectively, and stir at a constant speed for 8 hours at room temperature to form an aqueous solution with a mass fraction of 8%, and mix them at a ratio of 1:3. Add NaOH solution dropwise to form a uniform and stable spinning solution; then filter (use a tank filter to filter, the filter cloth is made of nylon, the pore size of the filter material is between 1200 mesh, the filter cartridge is made of stainless steel, and the filter pressure 0.1~0.5MPa), the spinning solution was degassed by centrifugation at 25°C for 45min, and the rotation speed was 4500r / min. Using the wet spinning process, a single-hole spinneret is used. The diameter of the spinneret hole is 0.08mm. The spinning liquid is extruded through the metering pump and the spinneret, and then enters an acidic coagulation bath at 25 ° C. The coagulation bath is pH = 1. hydro...

Embodiment 3

[0037] Raw materials: PAA, relative molecular mass: 450kDa; PEO, relative molecular mass: 600kDa.

[0038] Add PAA and PEO to water respectively, and stir at a constant speed at room temperature for 8 hours to form an aqueous solution with a mass fraction of 8%, and mix them at a ratio of 5:1. Add NaOH solution dropwise to form a uniform and stable spinning solution; then filter (use a tank filter to filter, the filter cloth is made of polypropylene, the pore size of the filter material is between 500 mesh, the filter cartridge is made of stainless steel, and the filter pressure 0.1~0.5MPa), the spinning solution was degassed by centrifugation at 25°C for 45min, and the rotation speed was 4500r / min. Using the wet spinning process, a single-hole spinneret is used. The diameter of the spinneret hole is 0.08mm. The spinning solution is extruded through the metering pump and the spinneret, and then enters an acidic coagulation bath at 40 ° C. The coagulation bath is pH = 1.5. sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com