Manufacturing method of methylamine lead iodine perovskite solar cell

A technology of solar cells and methylamine lead iodine, applied in the field of solar cells, can solve the problems of sensitivity to humidity, cumbersome preparation process, and inconspicuous performance improvement, and achieve a technology suitable for large-scale industrial manufacturing, simple preparation process, and outstanding cleaning ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

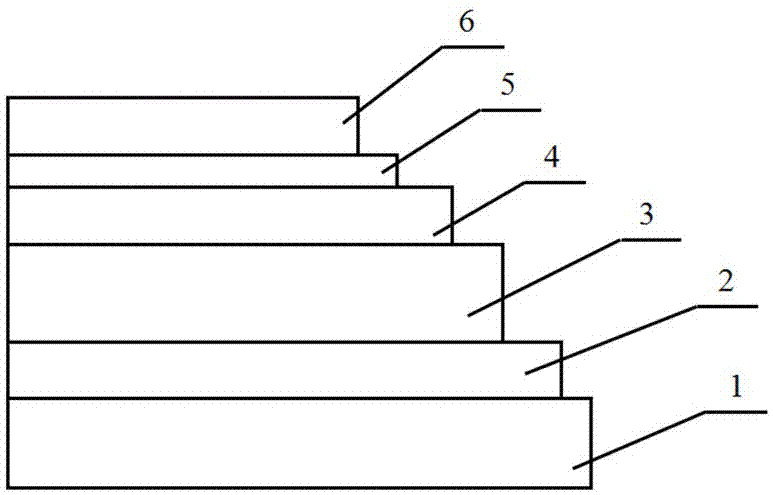

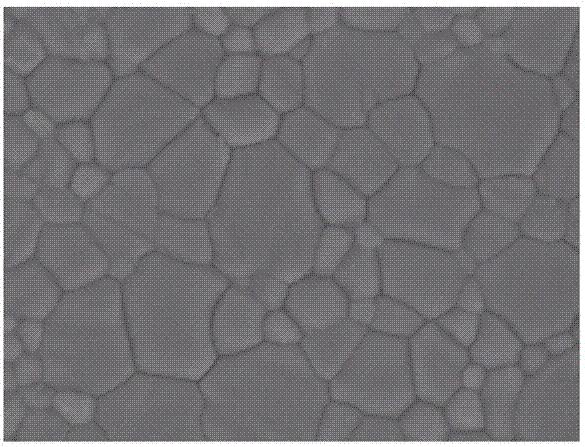

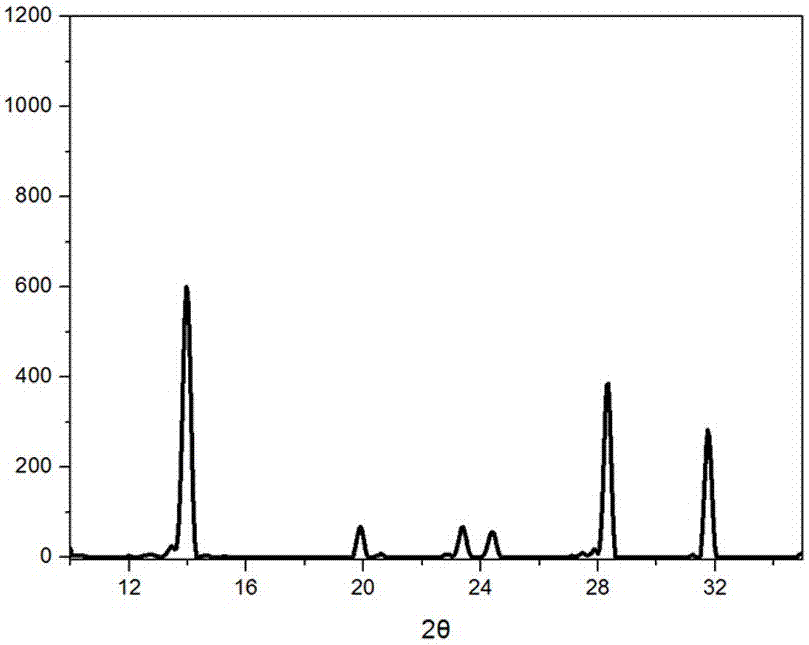

[0017] Such as figure 1 As shown, the thickness of the indium tin oxide (ITO) anode is 100 nm, and the ITO glass substrate is purchased from the manufacturer; the hole transport layer is poly(3,4-ethylenedioxythiophene)-polystyrenesulfonic acid (PEDOT:PSS) Purchased from Heraeus Company in Germany, model: AI4083, dilute the purchased PEDOT:PSS with deionized water according to the volume ratio of 3:2, and then use the solution spin coating method to form a film, and then heat treatment in the air. The spin coating speed is 4000rpm , the spin coating time is 30-40s, the heat treatment temperature is 150°C, the heating time is 10-15 min, the thickness of the PEDOT:PSS film is 20-30 nm, and the photosensitive layer is CH 3 NH 3 PB 3 Perovskite thin films, made of methylammonium iodide (CH 3 NH 3 I), lead iodide (PbI 2 ) was dissolved in a mixed solvent of N,N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) at a molar ratio of 1.05:1 to form CH 3 NH 3 PB 3 Perovskite...

Embodiment 2

[0022] This embodiment is a further optimization of Embodiment 1.

[0023] The methylamine lead iodine perovskite solar cell of the present invention has a planar heterojunction inverted structure: ITO / PEDOT:PSS / photosensitive layer / PC 60 BM / Bphen / Ag, the thickness of the ITO anode is 100 nm, the sheet resistance is 10Ω / □, the thickness of the hole transport layer PEDOT:PSS is 30 nm, the film is formed by the solution spin coating method, and then thermally annealed in the air, spin coating The speed was 4000 rpm, the spin coating time was 30 s, the heating temperature was 150 °C, the heating time was 15 min, and the photosensitive layer was CH 3 NH 3 PB 3 Perovskite thin films prepared from methylamine iodide (CH 3 NH 3 I), lead iodide (PbI 2 ) 1.05:1 molar ratio dissolved in N,N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) mixed solvent to form CH 3 NH 3 PB 3 Precursor solution, then made by spin-coating, sec-amyl alcohol cleaning process combined with annea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com