Novel rock cone crusher movable cone and using method thereof

A cone crushing and cone technology is applied in the field of new rock cone crushing motor cones, which can solve the problems of reduced work efficiency and low crushing quality, and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

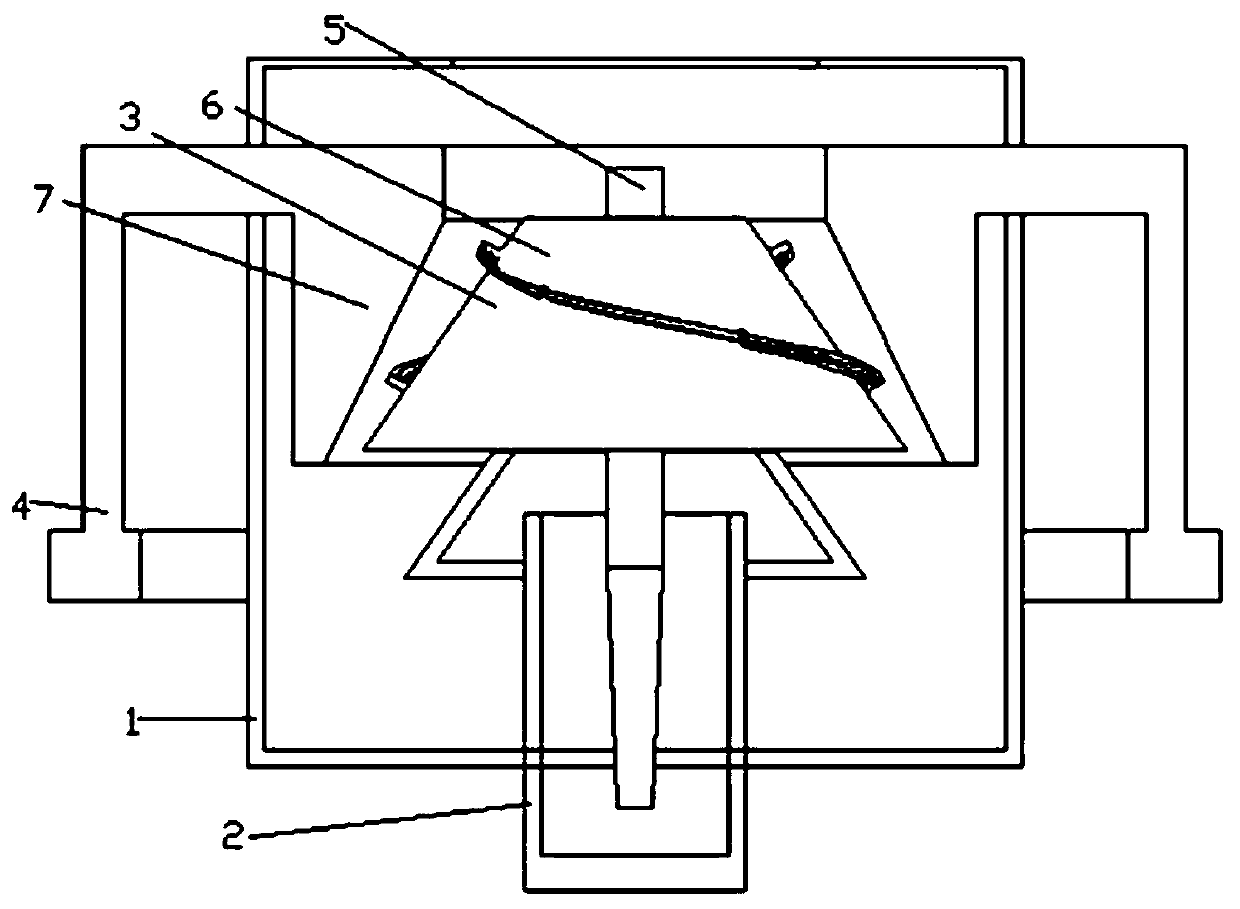

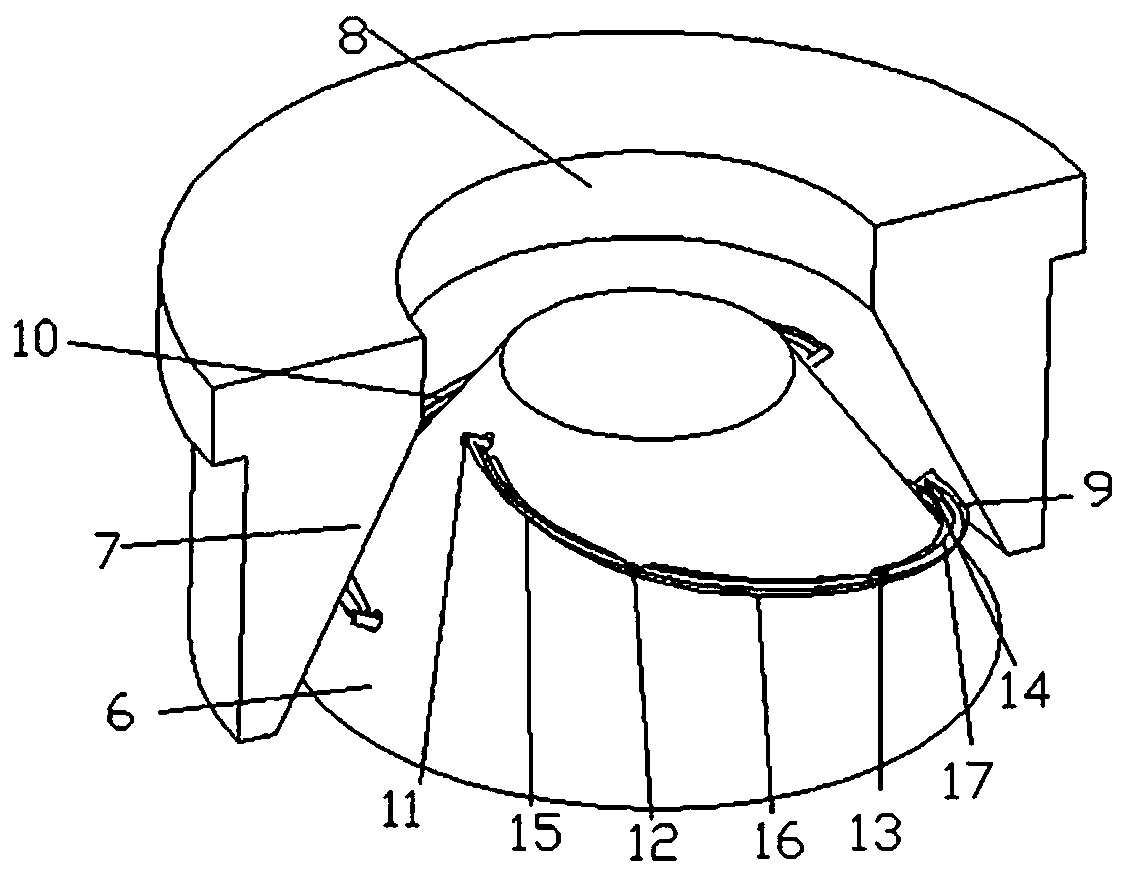

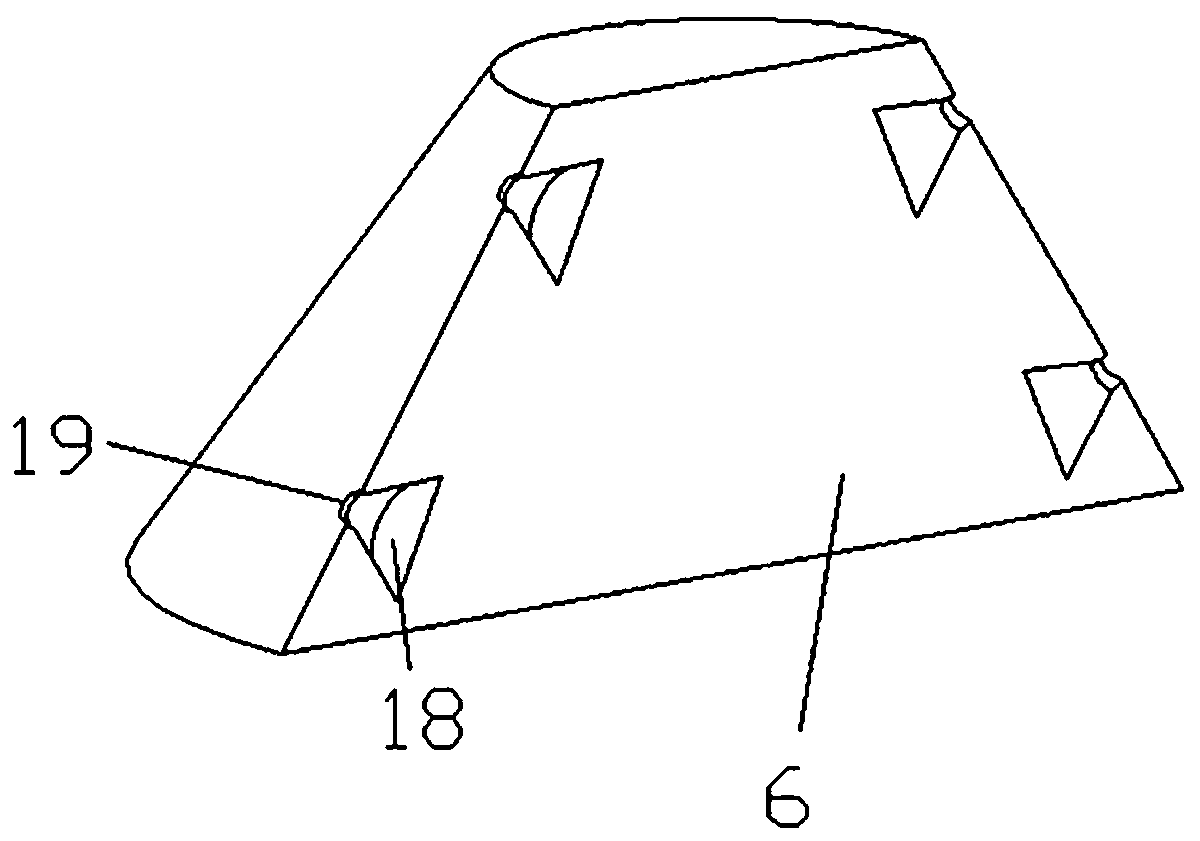

[0024] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, including frame 1, frame 1 is a cylindrical barrel structure, the top of frame 1 is provided with feed inlet 8, the bottom of frame 1 is equipped with shaft frame module 2, and shaft frame module 2 is equipped with spindle 5 , the upper relative position of the main shaft 5 is provided with a movable cone assembly 3, the relative position inside the frame 1 is provided with a crushing wall 7, the outer wall of the frame 1 is provided with a spring mechanism 4, the movable cone assembly 3 includes a movable cone body 6, and the movable cone The body 6 is a conical structure and the diameter of the top of the moving cone 6 is small, and the diameter of the bottom is large. The shape of the crushing wall 7 is similar to that of the moving cone 6. The position of the crushing wall 7 corresponds to the moving cone 6, and the front side of the moving cone 6 is opposite. The position and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com