A tea uniform crushing device

A crushing device and uniform technology, which can be used in pre-extraction tea treatment, solid separation, chemical instruments and methods, etc., and can solve the problems of low uniformity and large differences in crushing degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

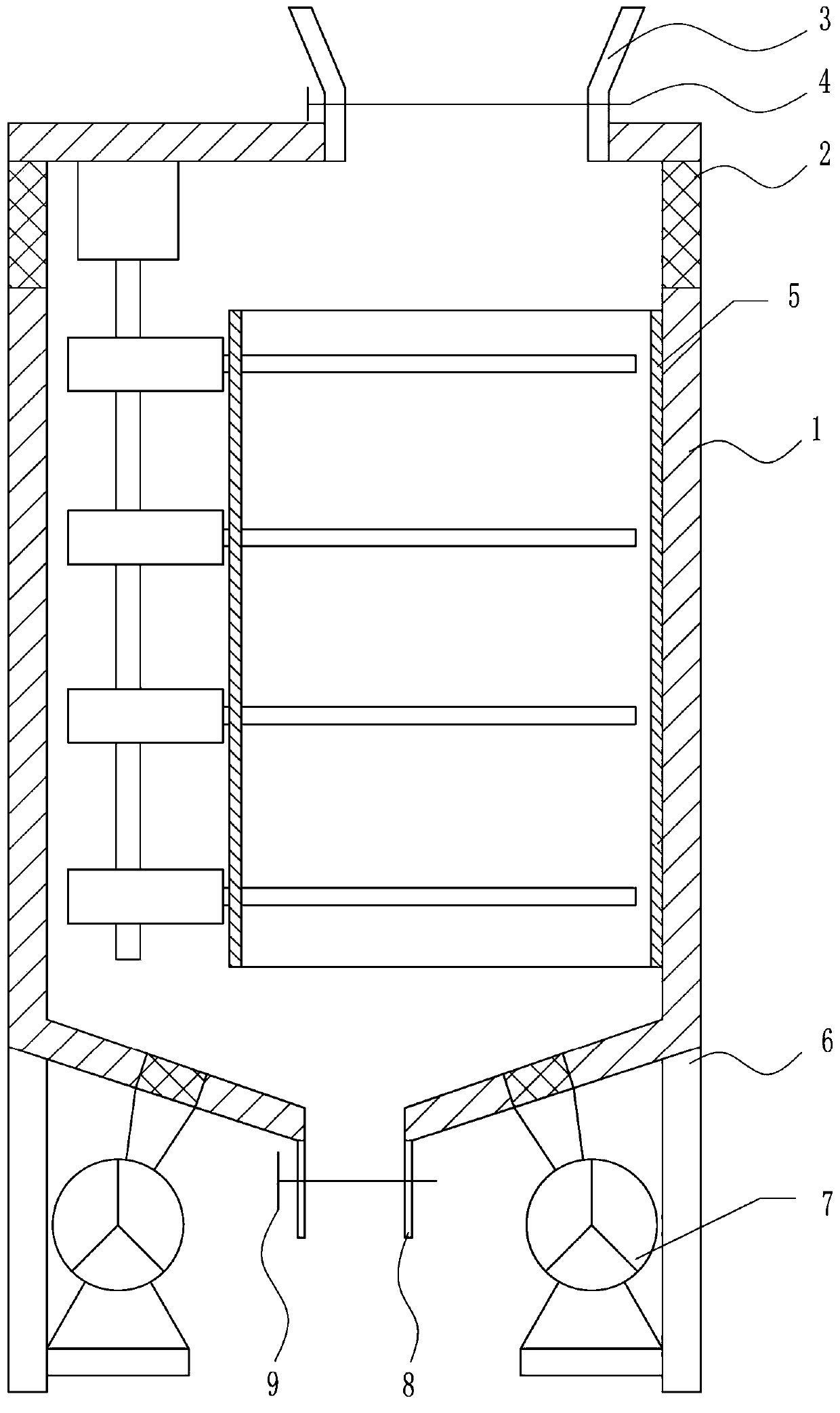

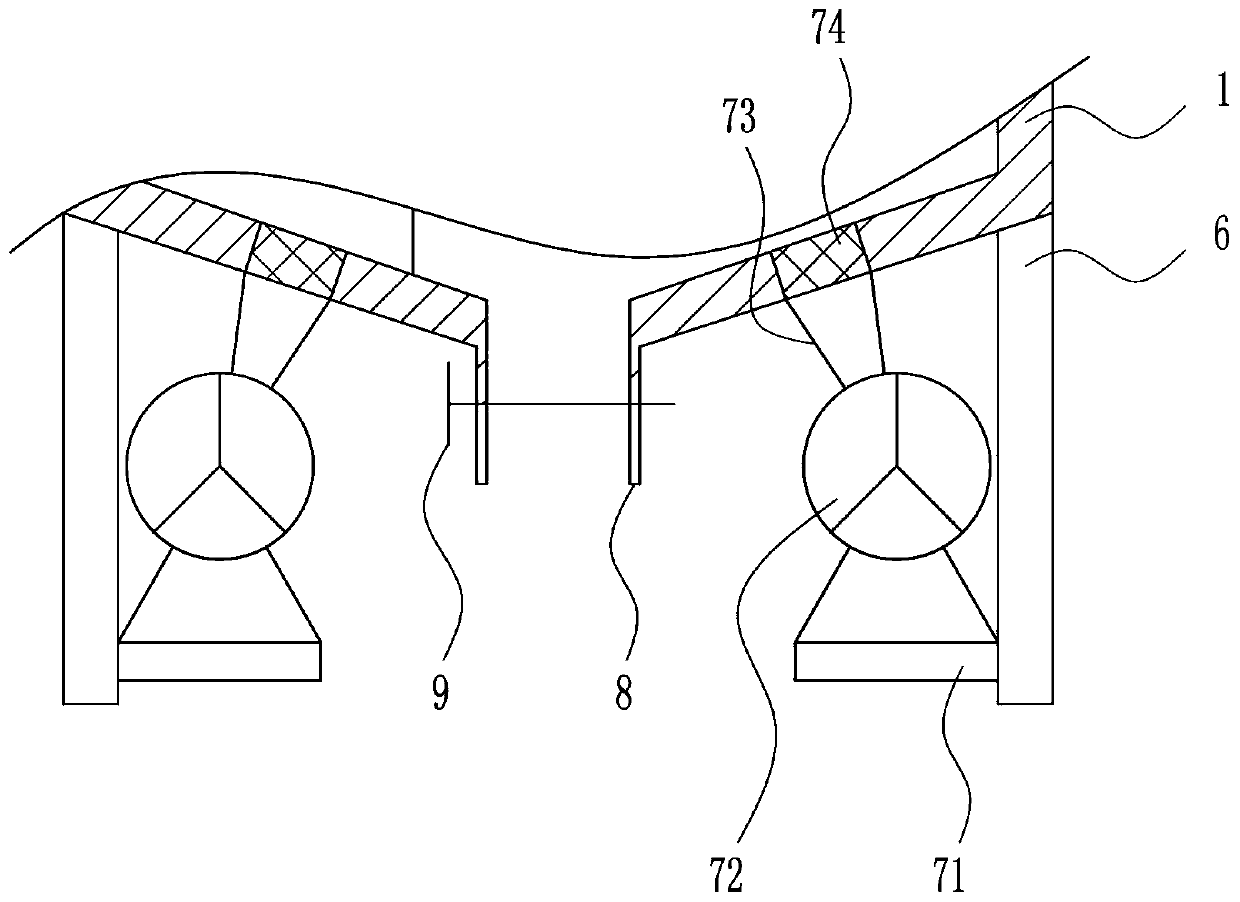

[0030] A device for evenly crushing tea leaves, such as Figure 1-6 As shown, it includes a crushing body 1, a first screen plate 2, a feed hopper 3, a first valve 4, a crushing mechanism 5, a frame 6, an air blast device 7, a discharge pipe 8 and a second valve 9, two left and right The side frame 6 is provided with a blower device 7, the blower device 7 is connected to the bottom of the crushing body 1, the top of the left and right sides of the frame 6 is installed with a crushing body 1, and the right side of the top of the crushing body 1 is provided with a feeding hopper 3. A first valve 4 is provided on the feed hopper 3, a crushing mechanism 5 is provided inside the crusher body 1, a discharge pipe 8 is provided in the middle of the bottom of the crusher body 1, and a second valve 9 is provided on the discharge pipe 8. 1. The upper part of the left and right side walls is symmetrically provided with a first mesh plate 2.

Embodiment 2

[0032] A device for evenly crushing tea leaves, such as Figure 1-6 As shown, it includes a crushing body 1, a first screen plate 2, a feed hopper 3, a first valve 4, a crushing mechanism 5, a frame 6, an air blast device 7, a discharge pipe 8 and a second valve 9, two left and right The side frame 6 is provided with a blower device 7, the blower device 7 is connected to the bottom of the crushing body 1, the top of the left and right sides of the frame 6 is installed with a crushing body 1, and the right side of the top of the crushing body 1 is provided with a feeding hopper 3. A first valve 4 is provided on the feed hopper 3, a crushing mechanism 5 is provided inside the crusher body 1, a discharge pipe 8 is provided in the middle of the bottom of the crusher body 1, and a second valve 9 is provided on the discharge pipe 8. 1. The upper part of the left and right side walls is symmetrically provided with a first mesh plate 2.

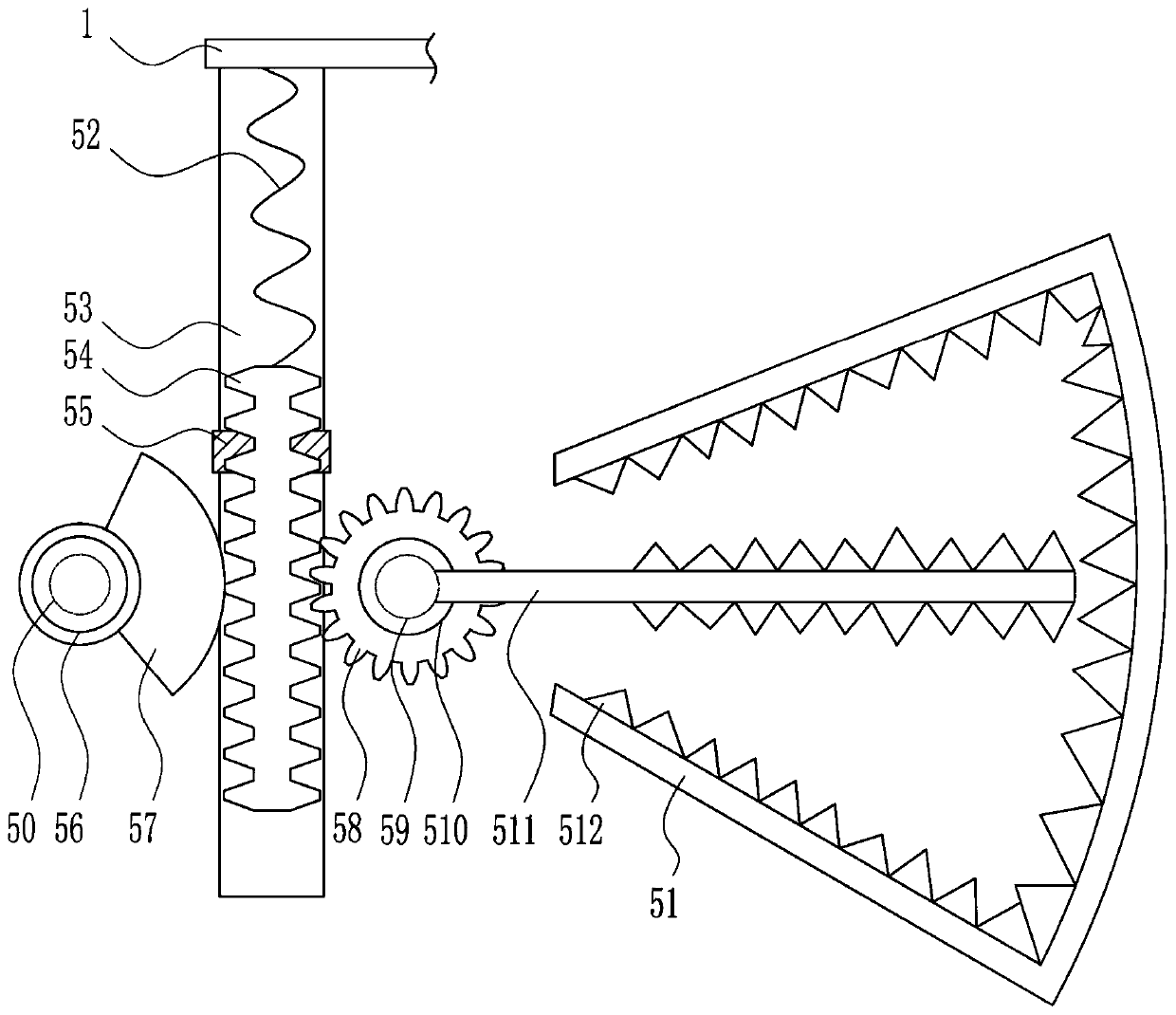

[0033]The crushing mechanism 5 includes a fir...

Embodiment 3

[0035] A device for evenly crushing tea leaves, such as Figure 1-6 As shown, it includes a crushing body 1, a first screen plate 2, a feed hopper 3, a first valve 4, a crushing mechanism 5, a frame 6, an air blast device 7, a discharge pipe 8 and a second valve 9, two left and right The side frame 6 is provided with a blower device 7, the blower device 7 is connected to the bottom of the crushing body 1, the top of the left and right sides of the frame 6 is installed with a crushing body 1, and the right side of the top of the crushing body 1 is provided with a feeding hopper 3. A first valve 4 is provided on the feed hopper 3, a crushing mechanism 5 is provided inside the crusher body 1, a discharge pipe 8 is provided in the middle of the bottom of the crusher body 1, and a second valve 9 is provided on the discharge pipe 8. 1. The upper part of the left and right side walls is symmetrically provided with a first mesh plate 2.

[0036] The crushing mechanism 5 includes a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com