Special micro-expansion corundum wear-resistant coating for waste heat air pipe

A wear-resistant coating and micro-expansion technology, applied in the field of wear-resistant coating materials, can solve the problems of substandard service life, loose combination of wear-resistant coatings and tortoise shell nets, shrinkage and drop of castables, etc., and achieve high compaction operation efficiency, Easy to adjust and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

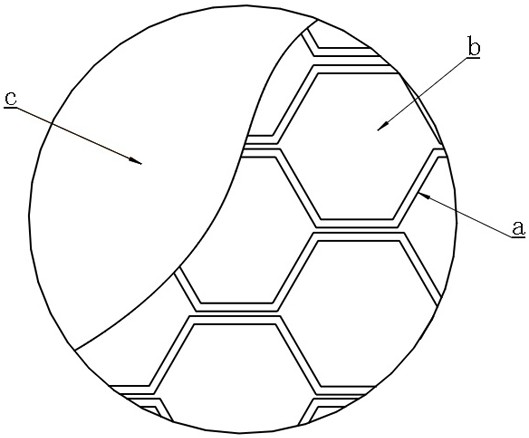

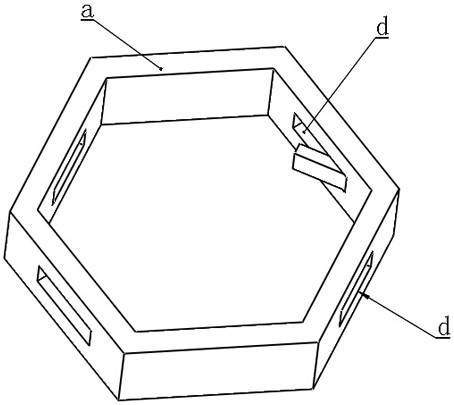

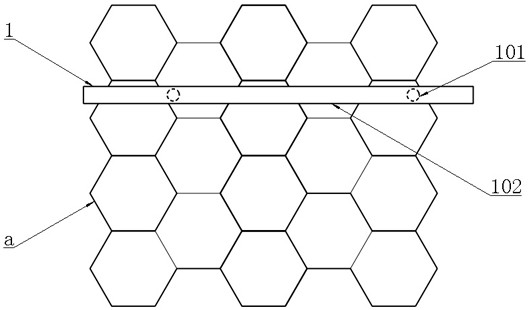

[0029] Example: as attached Figure 1-7 As shown, a special micro-expansion corundum wear-resistant paint for waste heat air ducts, including wear-resistant aggregates, composite expansion agents and plastic sintering aids, the wear-resistant paint is applied on the tortoise shell net a for use in waste heat air An inner liner c is formed in the pipe b.

[0030] In this embodiment, wear-resistant aggregates are used instead of ordinary aggregates in the prior art to ensure that the inner liner c has outstanding wear resistance, so that the inner liner c contains a large amount of solid particles It can remain effective for a long time under the dust, and the composite expansion agent has the characteristics of micro-expansion when heated, which is different from the characteristics of shrinkage of the existing wear-resistant coatings at high temperatures in the prior art, so that the wear-resistant coatings in this embodiment are used During the process, the tortoise shell ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com