Pre-added axial force based circular support system in shield tunnel and construction method of system

A shield tunneling and support system technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of impassable construction vehicles, difficult operation of prestress, and large space occupation, so as to ensure normal traffic and save construction period , the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in combination with specific embodiments.

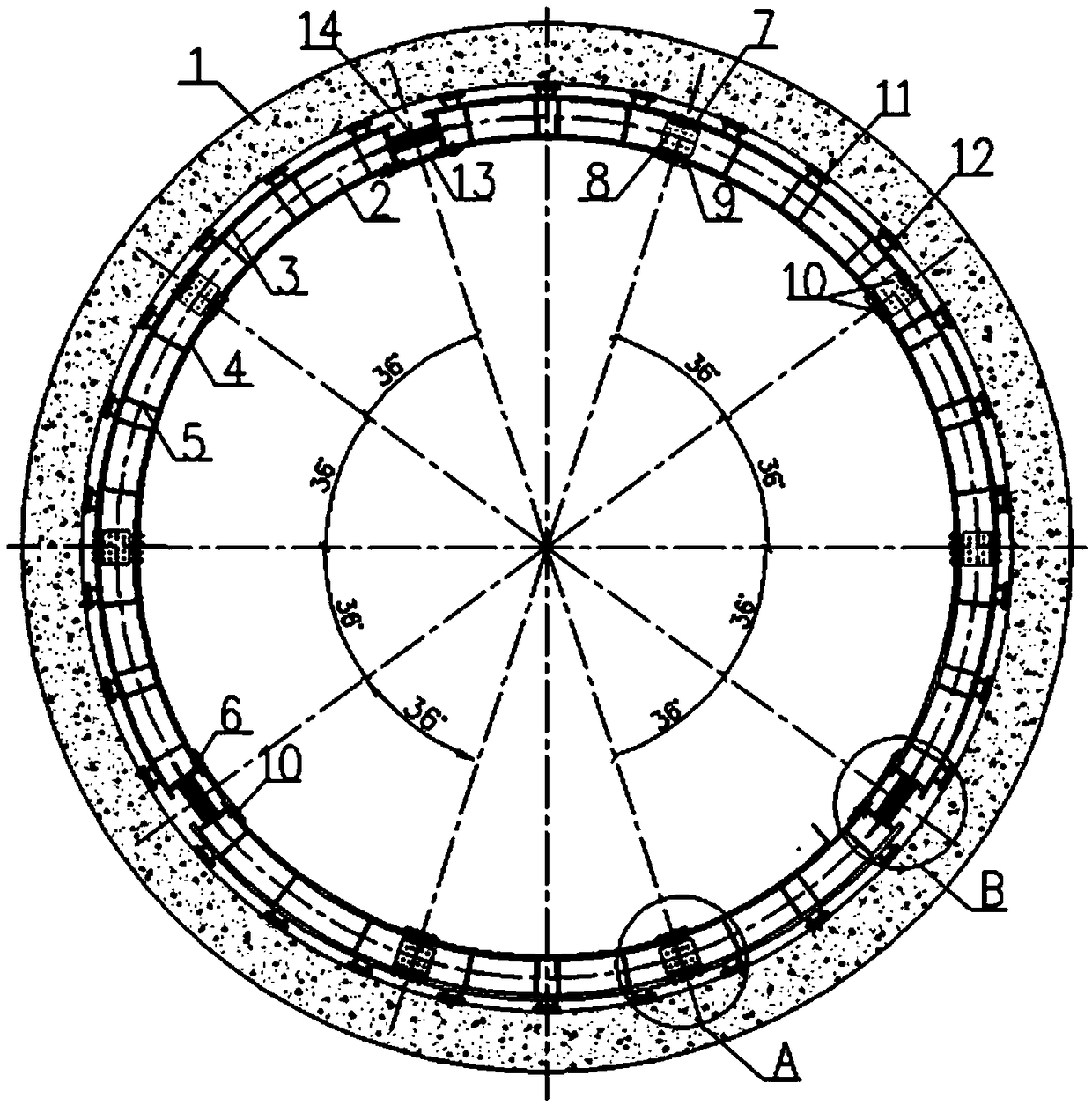

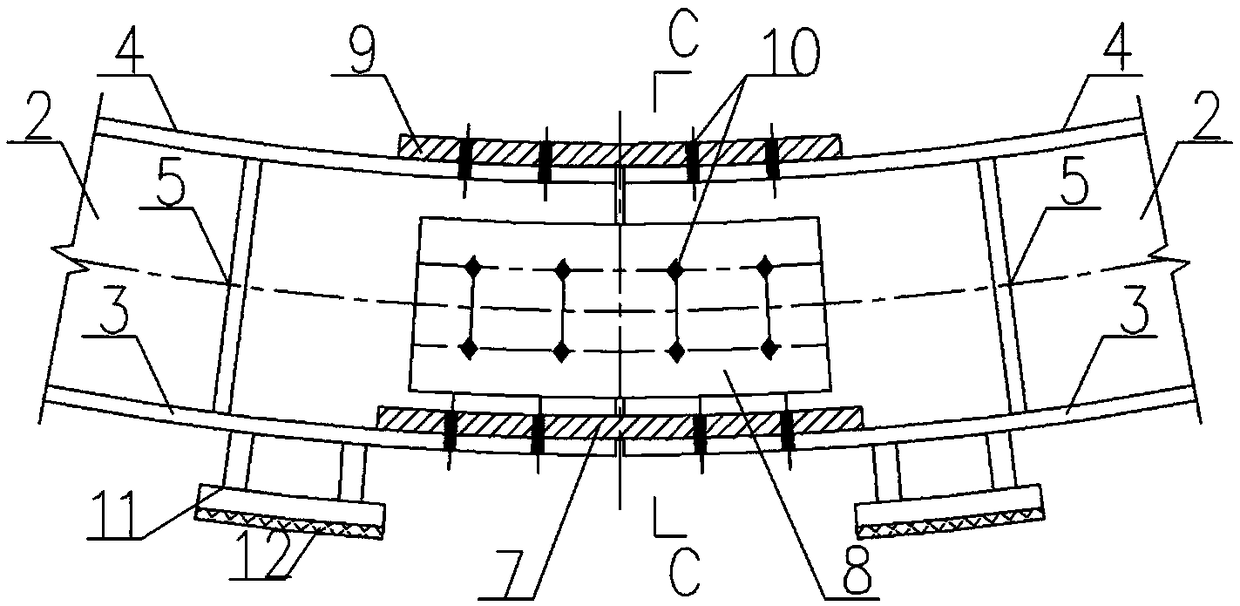

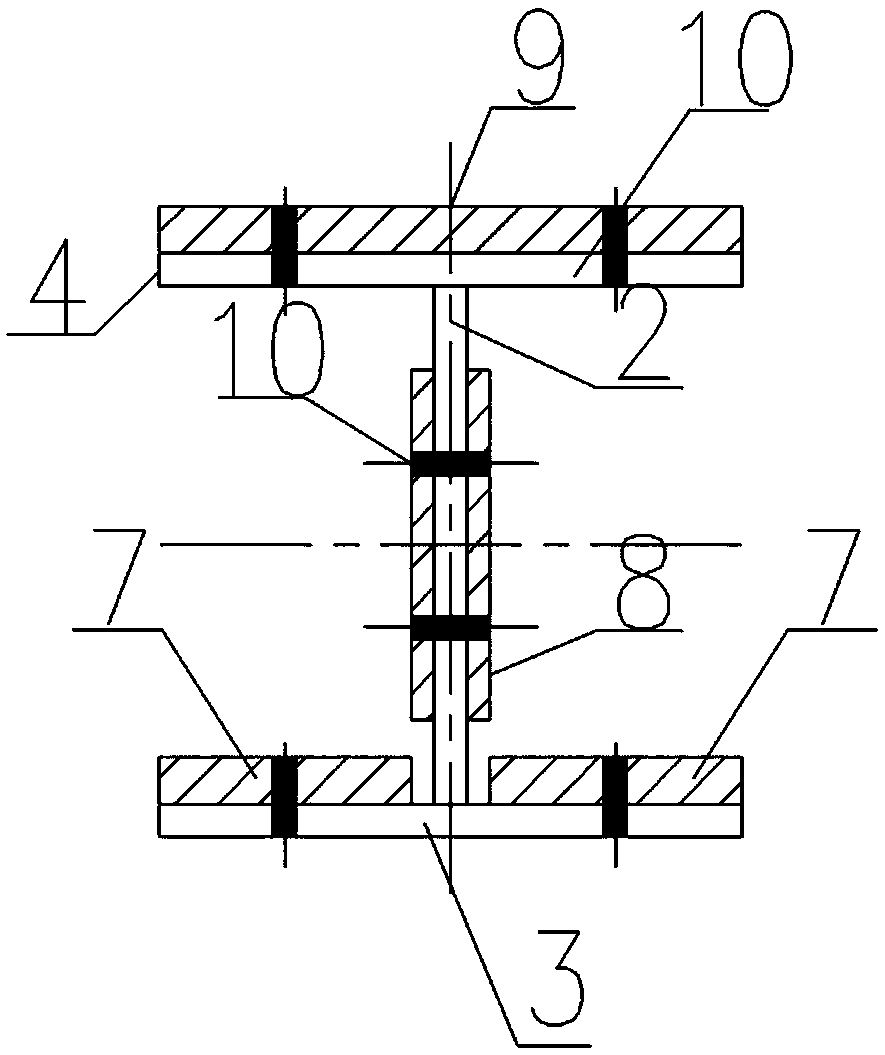

[0038] The invention relates to a circular support system in a shield tunnel based on pre-applied axial force, which is a combination welded by section steel and steel plates, connected by connecting steel plates and bolts, and then formed into a continuous, rigid, pre-loaded support system by a jack. The stress of the overall support system, so as to achieve the purpose of forming an effective reinforcement support for the segment.

[0039] Specifically, the structure includes an annular shaped steel and steel plate combination in the shield segment 1, and a support 11 perpendicular to the shield segment 1 is arranged between the shaped steel and steel plate combination and the shield segment 1. The combination of section steel and steel plate is divided into multiple sections in the circumferential direction, and each section includes arc-shaped section steel. The arc-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com