Method and system for crushing and cooling high-temperature solid waste residue blocks

A cooling system and waste slag technology, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of slow cooling speed, smashed conveying equipment, burnt conveying belt, etc., to prolong the cooling time, good cooling effect, Shattered uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

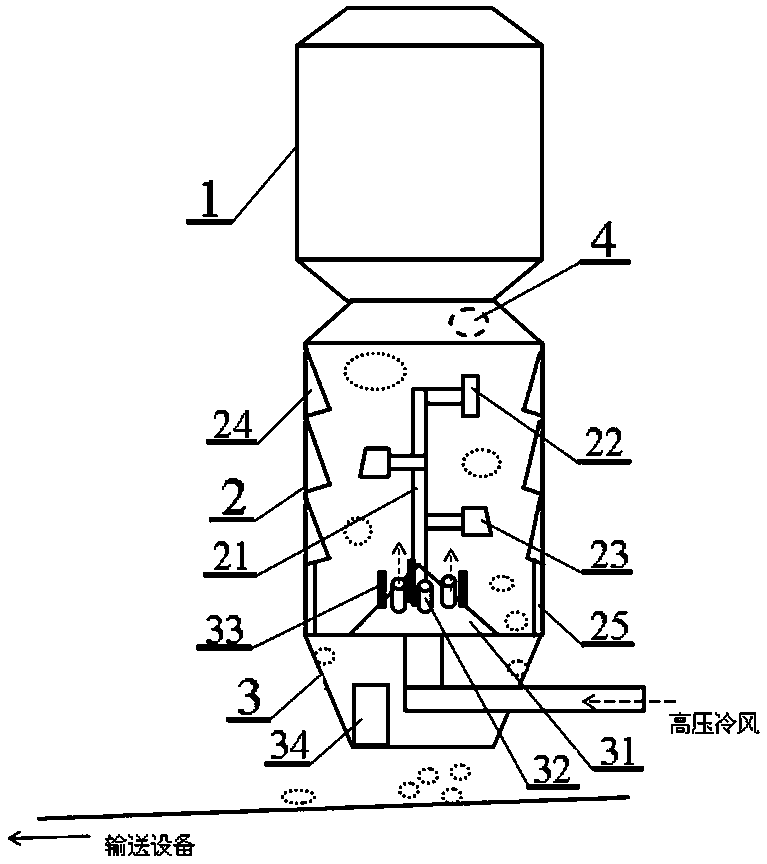

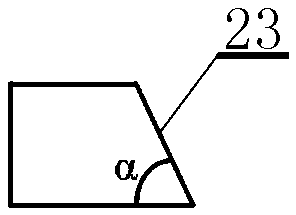

[0030] Such as figure 1 As shown, this embodiment provides a crushing and cooling system for high-temperature solid waste slag blocks. The system includes a garbage incinerator 1, a crushing chamber 2, and a collection bin 3 from top to bottom. The middle part of the crushing chamber 2 is cylindrical. There is a heat-resistant steel vertical shaft 21 installed on the bottom of the cylinder. Three rows of hammer shafts are installed on the vertical shaft 21. There is a hammer head on the hammer shaft. The hammer head is made of high manganese steel and has been heat-treated. The radius of rotation of the hammerhead decreases gradually from top to bottom, and the weight of the hammerhead also gradually decreases from top to bottom, as figure 2 As shown, the uppermost hammer head is a square hammer head 22, such as image 3 As shown, the hammer heads of the second layer and the third layer are right-angled trapezoidal hammer heads 23, and the right-angled sides of the right-ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com