Cotton separating device

A separation device, cotton technology, applied in the direction of separating plant fibers from seeds, etc., can solve the problems of large volume, complex structure and difficulty in sharing of shelling machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

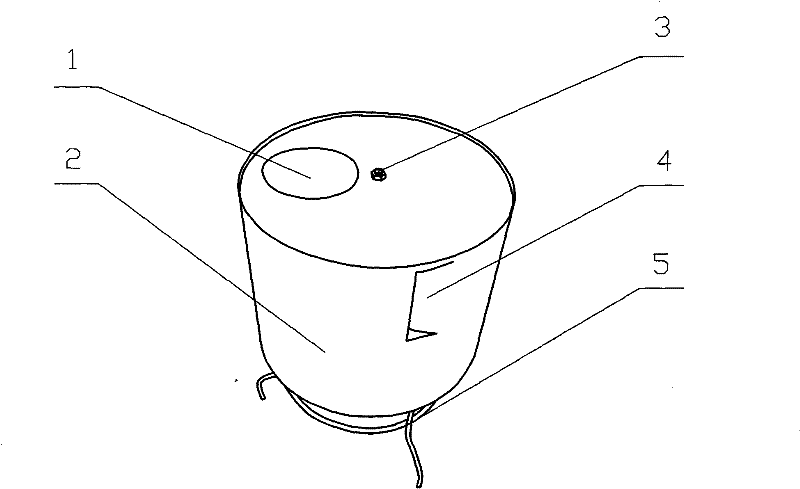

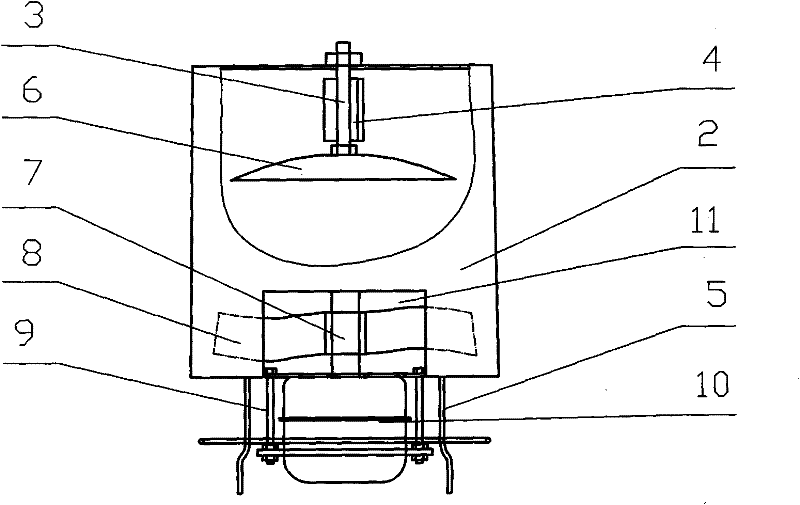

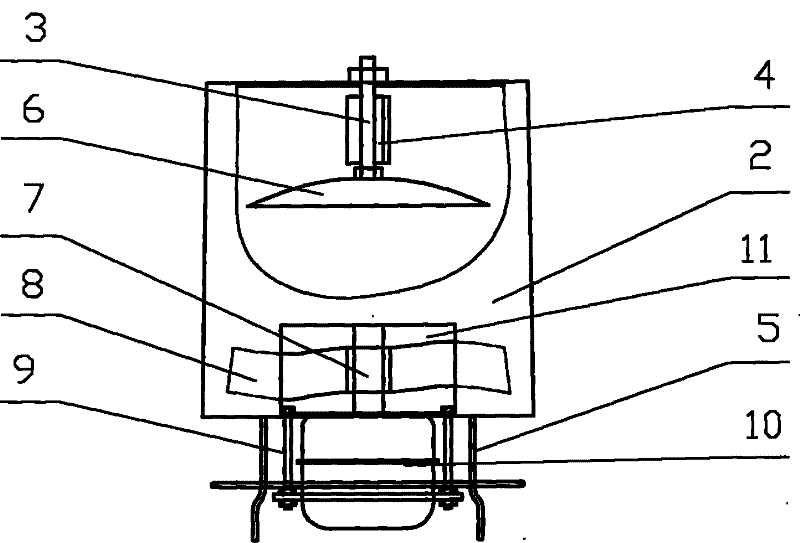

[0013] Such as figure 1 , figure 2 A kind of cotton separating device shown, it comprises housing 2 and support 5, and motor 10 is installed on the support 5, and motor drives the working mechanism in the housing, and housing has feeding port 1 and cotton outlet 11, and housing 2 It is a cylindrical cylinder, and the bracket 5 is located below the shell 2 and supports the cylinder; the upper surface of the shell 2 has a circular feeding port 1, and the upper side wall of the shell has a debris outlet 4, and the debris The outlet 4 is a "匚" shape cut out on the side wall of the housing, and the cut out part of the side wall protrudes into the inside of the housing. The lower part of the upper side wall of the housing 2 is provided with a cotton outlet 11 relative to the debris outlet 4; a motor 10 is fixed on the support, and the motor 10 is connected with the lower surface of the housing 2 through a flange and a fixed screw rod 9. The output shaft 7 passes upwards through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com