Simple tire semi-finished product joint pressing machine

A semi-finished and simple technology, applied to tires, other household appliances, household appliances, etc., can solve the problems of reducing tire quality and production efficiency, unreliable pressing, increasing waste rate, tire manufacturing costs, etc., to achieve a compact structure Stable and defect-free, fast compaction, good promotion and use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

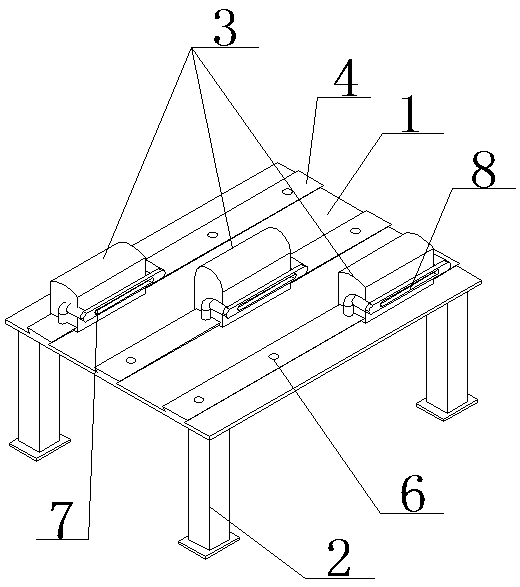

Embodiment 1

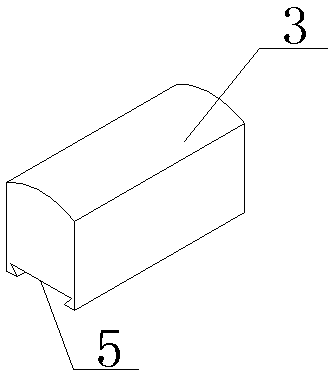

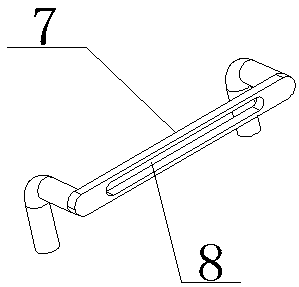

[0027] A simple tire semi-finished joint compactor according to the present invention comprises a support plate 1, and support legs 2 are arranged at the bottom of the support plate 1, and the support legs 2 are arranged in an even number and symmetrically fixed on the bottom of the support plate 1; the support plate 1 The top is movable and provided with 3 compacting plates 3 with a rectangular block structure with a curved top; 3 bosses 4 with a dovetail structure are arranged on the support plate 1, and the 3 bosses 4 are arranged in parallel, and the bosses 4 It is integrally formed with the support plate 1, and the bottom of the compaction plate 3 is provided with a dovetail-shaped structural groove 5 that matches the boss 4, and the boss 4 is connected with the groove 5 so that the compaction plate 3 and the support plate 1 are slidably matched connected; each boss 4 is provided with four limit holes 6, and the length of two adjacent limit holes 6 is equal to the plate le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com