Negative pressure compactor for quilt netting twine

A technology of compactor and negative pressure cotton, which is applied to textiles, papermaking, non-woven fabrics, household appliances, etc., and can solve the problems of high labor intensity, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

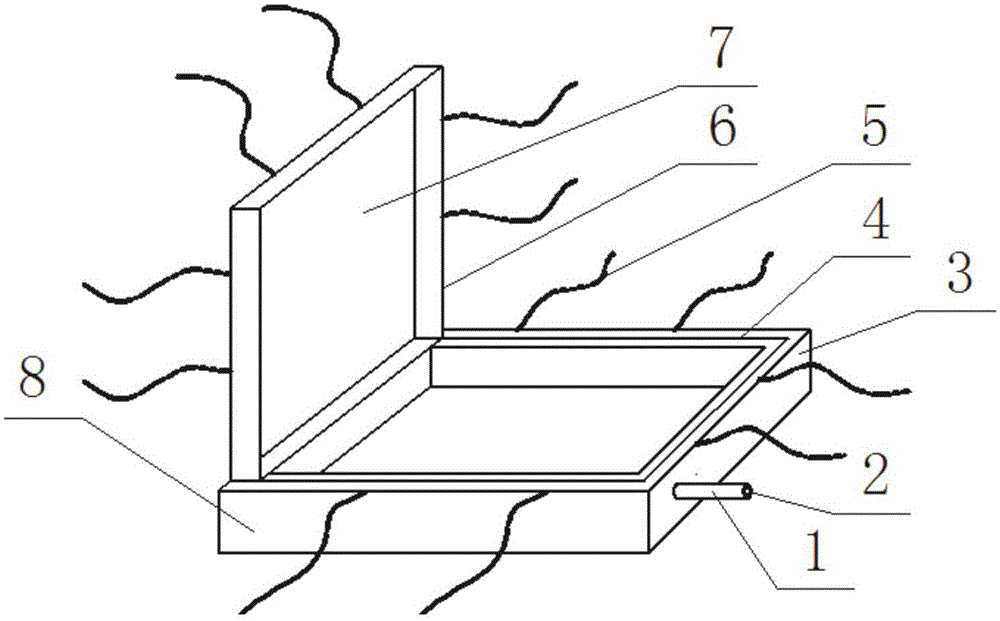

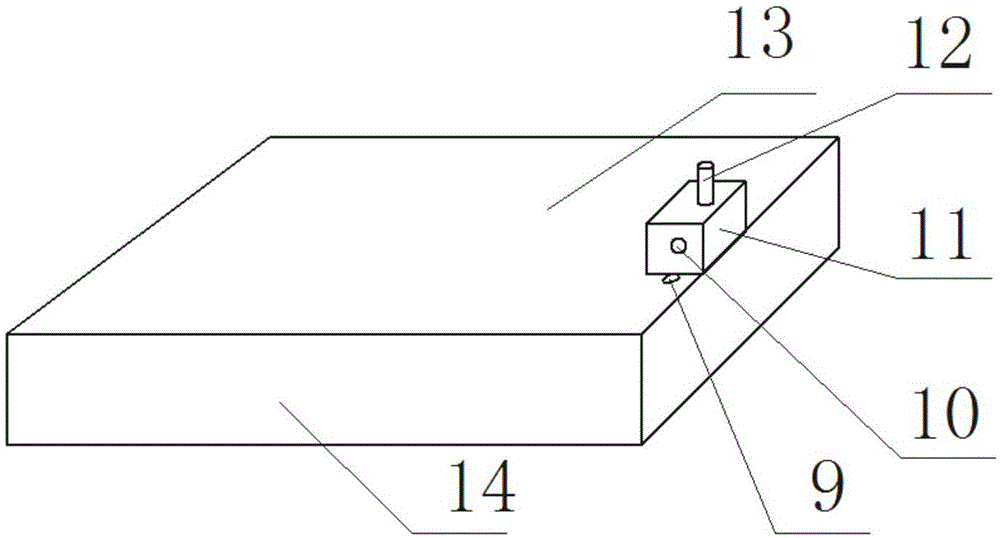

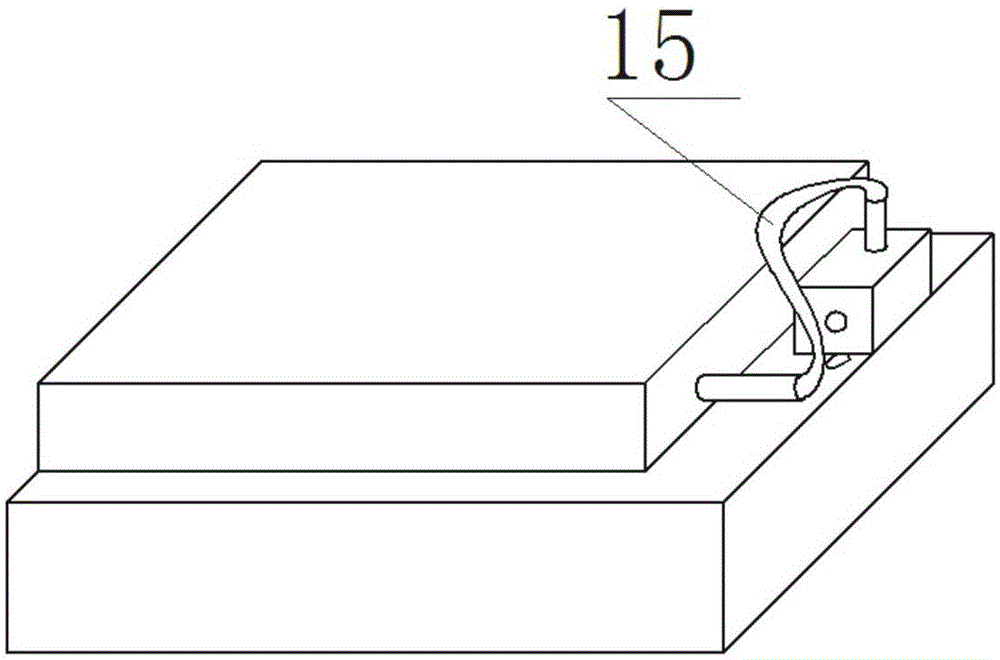

[0012] Such as Figures 1 to 3 As shown, the negative pressure quilt wire compactor of the present invention mainly includes a quilt bag body 8 and a machine base 14 .

[0013] The quilt bag body includes a square bag bottom 3 and a bag surface 7, the bag bottom and the bag surface are connected as a whole through a corresponding side, the other three sides that can be opened on the upper surface of the bag bottom are provided with sealing sockets 4, and the lower surface of the bag surface can be opened The other three sides of the bag are provided with sealing inserts 6 corresponding to the sealing sockets, and the sealing inserts and the sealing sockets can be combined into a sealed whole; two corresponding positions on the other three sides where the bottom of the bag and the bag surface can be opened are respectively installed with a total of six pairs of tight fittings. Solid band 5; Stretch out trachea joint 1 on the right end at the bottom of the bag, and the ventilati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com