Semi-solid molding equipment and process for non-ferrous metal particles

A semi-solid forming, non-ferrous metal technology, used in metal processing equipment, equipment for supplying molten metal, casting equipment, etc., can solve problems such as difficulty in forming large billets, restricting application scope, etc., achieving good compactness, saving manufacturing costs, The effect of a short turnaround time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

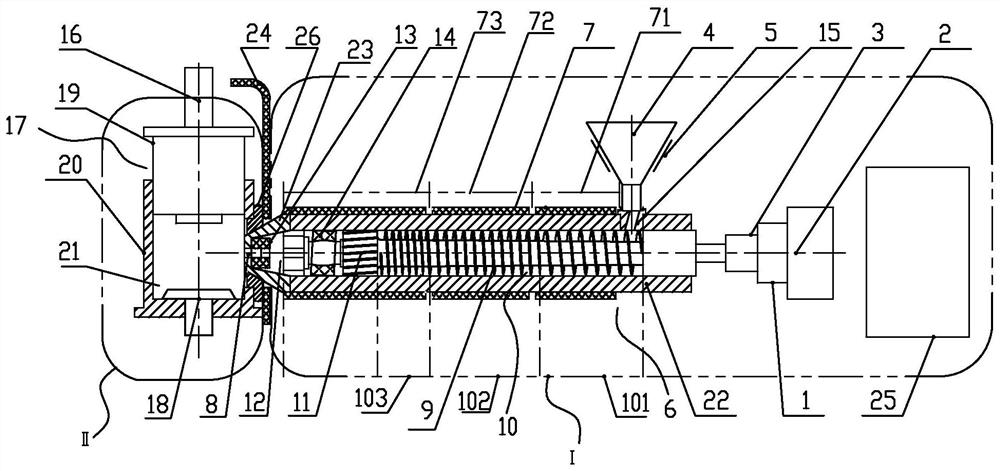

[0039] exist figure 1 , figure 2 In the illustrated embodiment, a semi-solid molding device for non-ferrous metal particles includes:

[0040] One-section horizontal feeding mechanism I, one-section horizontal feeding mechanism is used to realize the conveying, melting, mixing, storage, and feeding of metal particles into the molding cavity; one-section horizontal feeding mechanism includes quantitative control system 1 , feed pressure system 2, feed rotation system 3, material storage device 4, drying system 5, barrel device 6 and segmental gradient heating system 7;

[0041] Two-section vertical forming mechanism II, the two-section vertical forming mechanism is used to realize die forging and die-casting;

[0042] The working direction of the horizontal feeding mechanism of the first section is vertical to the working direction of the vertical forming mechanism of the second section, and the horizontal feeding mechanism of the first section is connected with the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com