Tamping and trowelling device for building concrete laying

A concrete and construction technology, applied in the processing of building materials, construction, soil protection, etc., can solve the problems of machine tamping and leveling, waste of manpower, etc., and achieve the effect of saving manpower and material resources, high work efficiency, and smooth ground.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

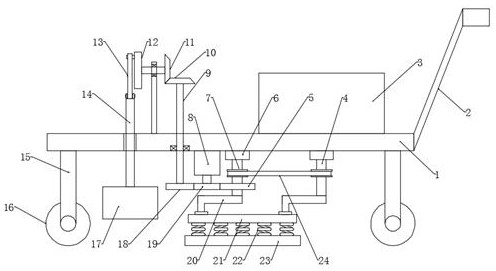

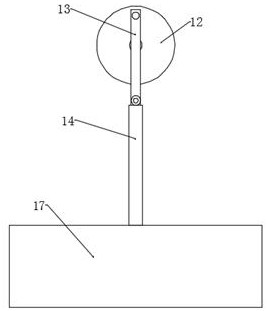

[0024] see Figure 1~2 , in an embodiment of the present invention, a tamping and leveling device for building concrete laying, comprising a base plate 1 and a tamping block 17, support legs 15 are fixed on the four corners of the bottom of the base plate 1, and the bottom ends of the support legs 15 are installed with The roller 16, the roller 16 is a self-locking roller, the right end of the base plate 1 is fixed with the hand frame 2, the tool box 3 is installed on the right side of the upper surface of the base plate 1, the motor 8 is installed in the middle of the bottom of the base plate 1, and the end of the output shaft of the motor 8 is installed There is a first gear 19, the left side of the first gear 19 is provided with a second gear 18, the second gear 18 meshes with the first gear 19, the second gear 18 is installed on the bottom end of the first rotating shaft 9, and the other end of the first rotating shaft 9 runs through The base plate 1 extends to the top of ...

Embodiment 2

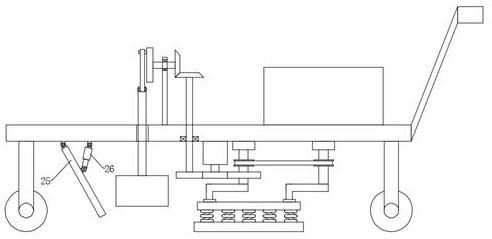

[0026] see image 3 , The difference between this embodiment and Embodiment 1 is that it also includes a tiling mechanism, and the tiling mechanism includes a tiling plate 25 and an electric push rod 26. 1 The lower surface is located on one side of the tiled board 25, and an electric push rod 26 is hingedly installed. The end of the telescopic rod of the electric push rod 26 is hinged with the side wall of the tiled board 25. On the ground, by controlling the stretching or shortening of the telescopic rod of the electric push rod 26, the distance between the bottom end of the tiled board 25 and the ground is adjusted, so that the concrete can be tiled with different thicknesses according to the operation requirements to meet the needs of different situations .

[0027] The working principle of the present invention is: when the present invention is in use, push the device to the working position, then start the motor 8, the motor 8 drives the first gear 19 to rotate, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com